Apparatus and method for using a viscoelastic cleaning material to remove particles on a substrate

A cleaning material, viscoelastic technology, applied in the field of apparatus and method for removing particles on a substrate using a viscoelastic cleaning material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Detailed description of the preferred embodiment

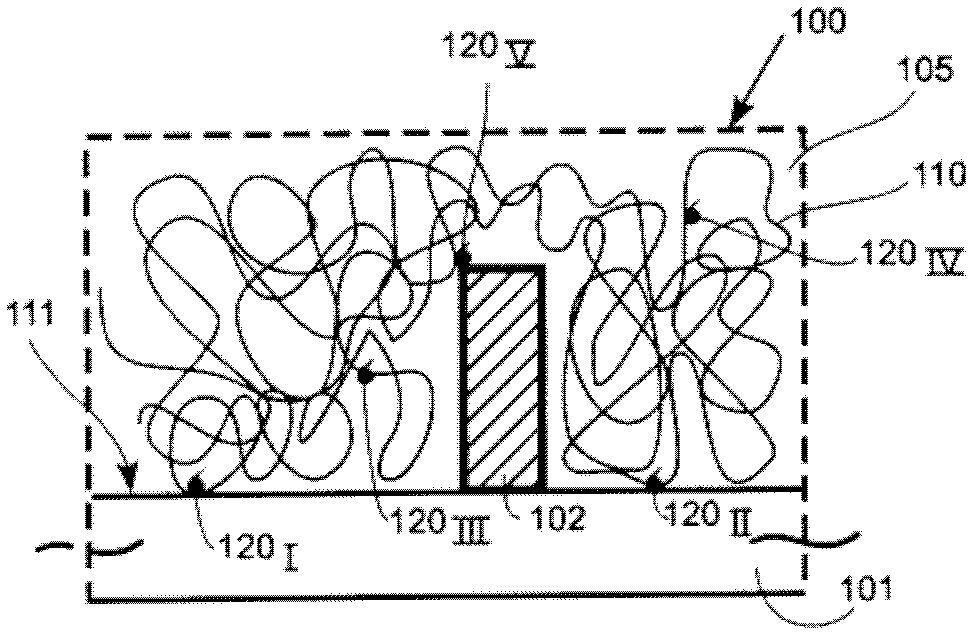

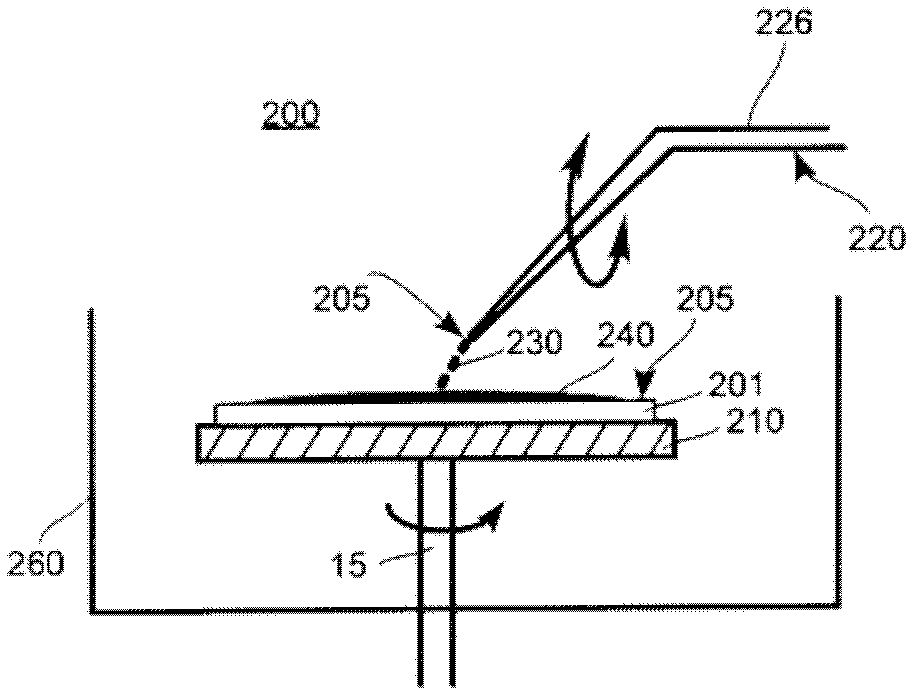

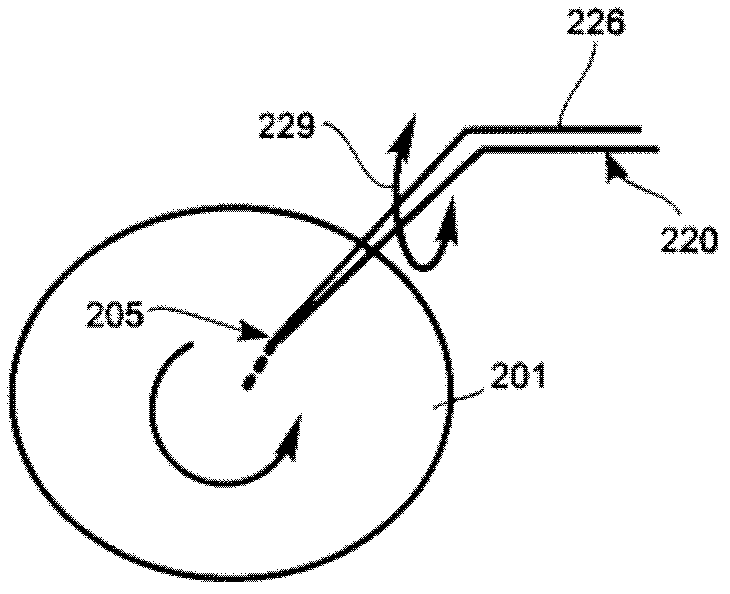

[0042] Embodiments of materials, methods, and apparatus for cleaning wafer surfaces without damaging surface features are described. The cleaning materials, devices, and methods discussed here have advantages in cleaning patterned substrates with fine features without damaging surface features. The cleaning material is fluid, in a liquid or liquid / gas phase, and deforms around the device features; thus, the cleaning material does not damage the device features. The cleaning material comprises polymers with large molecular weights, such as greater than 10000 g / mol, and traps contaminants on the substrate. In addition, the cleaning material captures the contaminants and does not return the contaminants to the substrate surface. The large molecular weight of the polymer chains enhances the trapping and trapping of particulate pollutants compared to conventional cleaning materials.

[0043] It will be apparent, however, to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com