Patents

Literature

33results about How to "Shear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

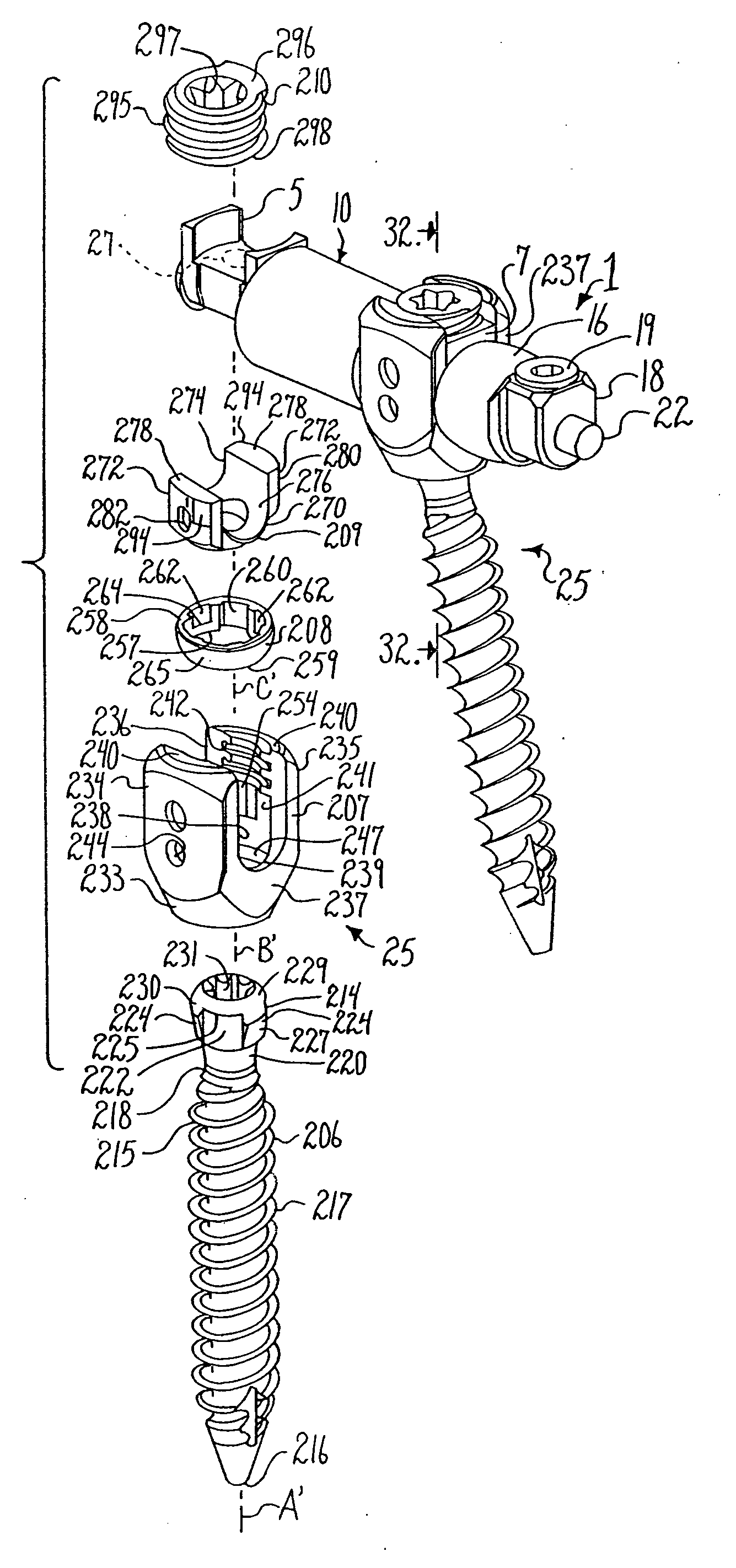

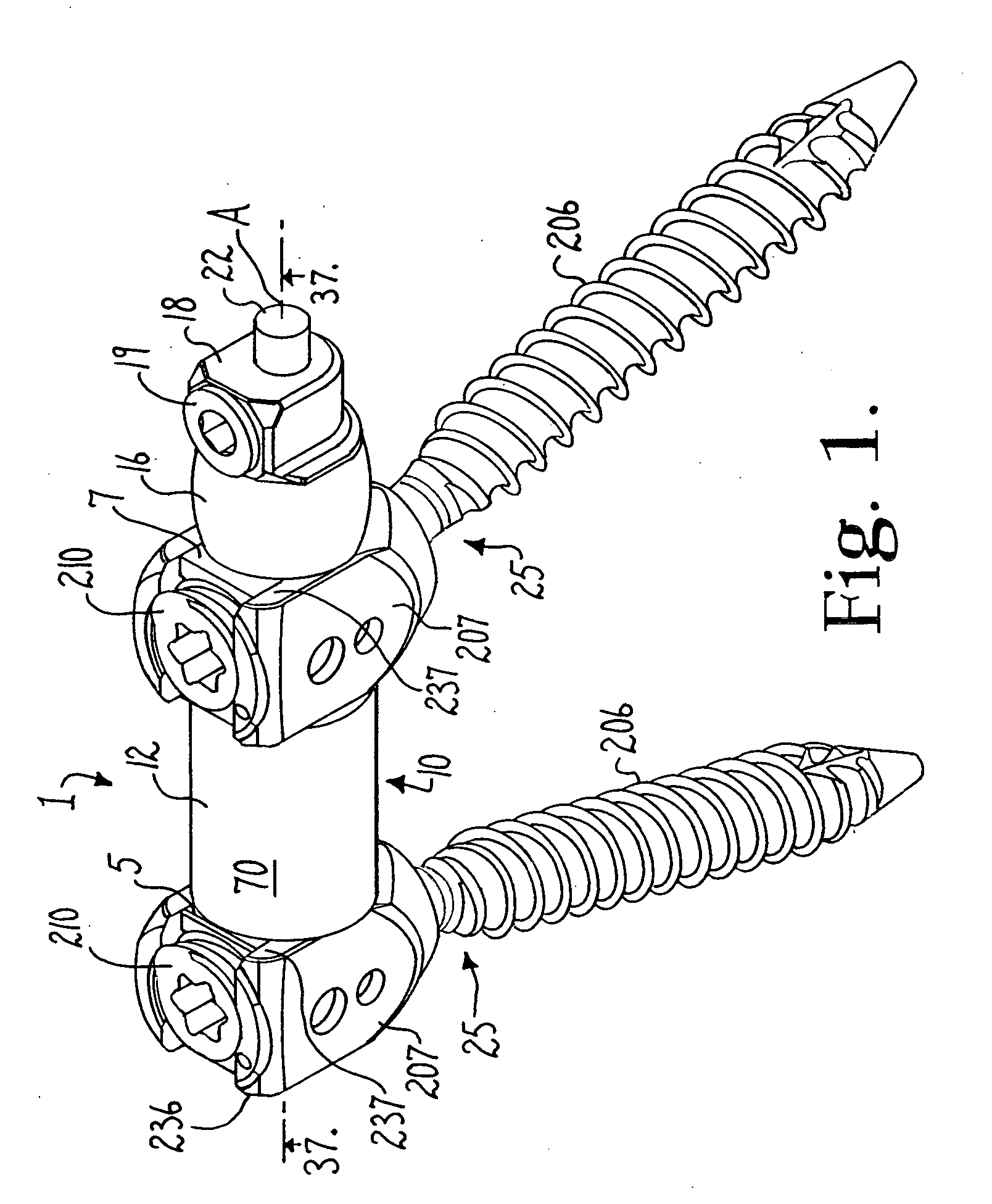

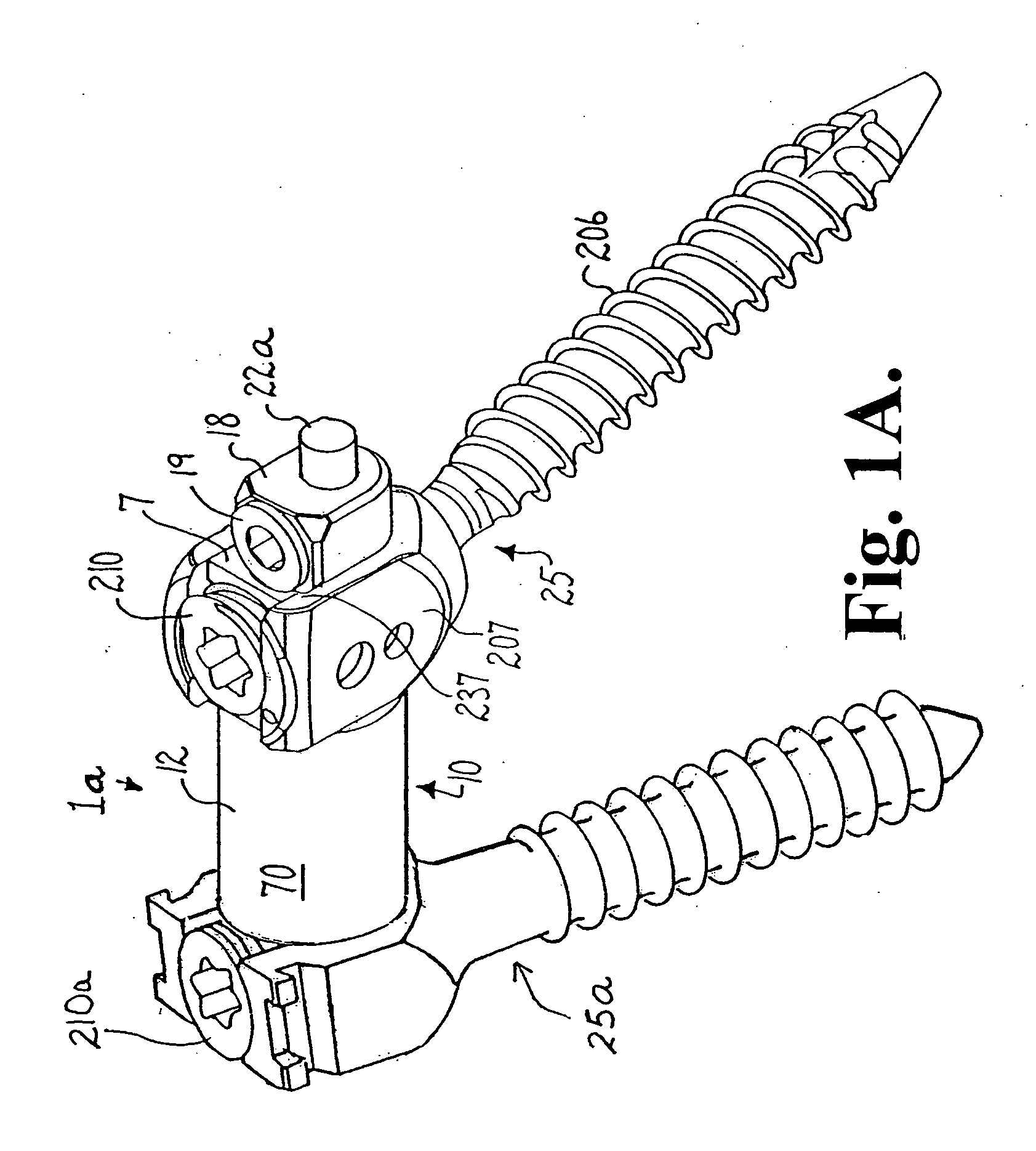

Longitudinal connecting member with sleeved tensioned cords

InactiveUS20100331887A1Variable segmental stiffnessFlexibility in bendingInternal osteosythesisJoint implantsDynamic fixationBiomedical engineering

A dynamic fixation medical implant having at least two bone anchors includes a longitudinal connecting member assembly having rigid sleeves for attachment to the bone anchors, at least one spacer engaging the bone anchors and the sleeves, and in some embodiments, an end elastic bumper. A flexible cord is initially slidingly received within the rigid sleeves, the spacer and the bumper. The spacer may include an optional inelastic inner liner, with at least one of the sleeves having an extension slidingly receivable within the liner. Some sleeves include apertures for receiving a closure top portion for locking the cord against the sleeve, or alternatively receiving a closure top that does not extend into the aperture, the slip or grip option provided by the aperture in each sleeve resulting in an overall connector with variable segmental stiffness.

Owner:JACKSON ROGER P

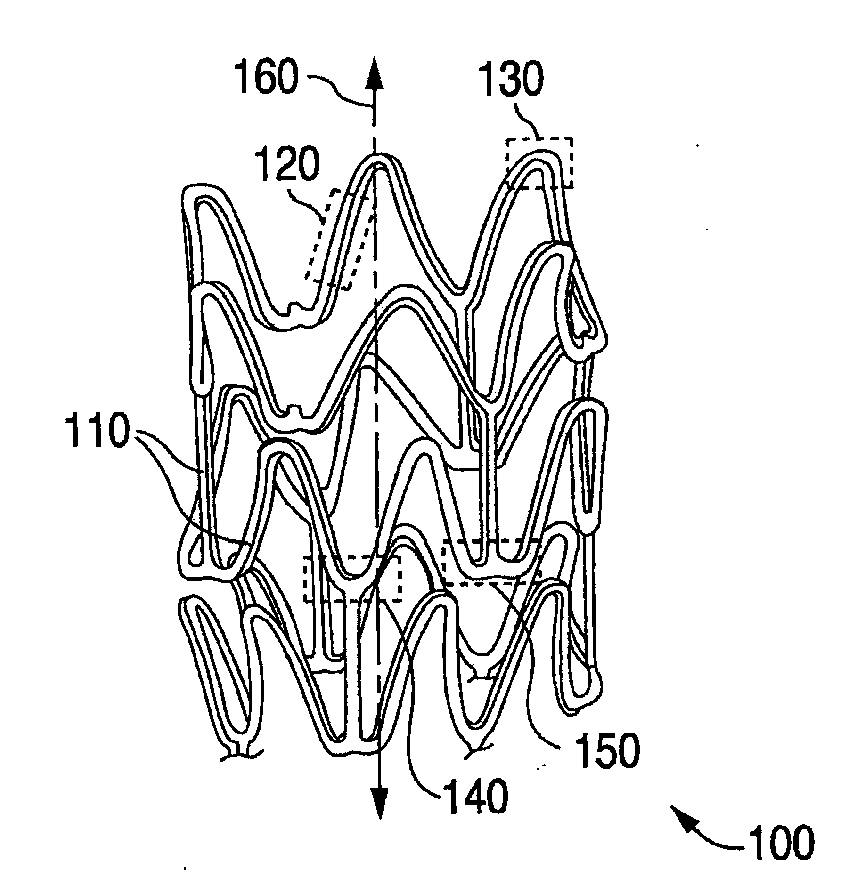

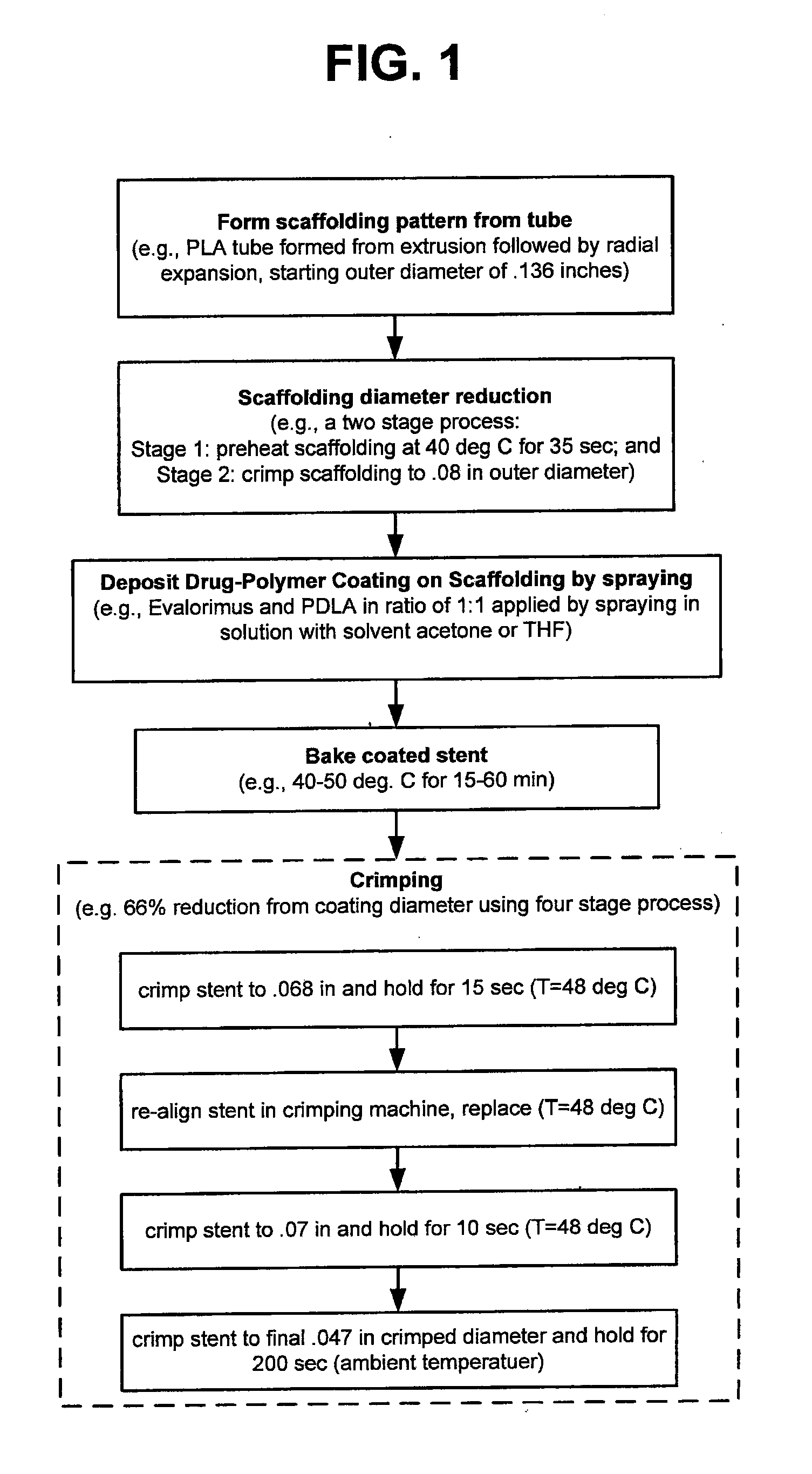

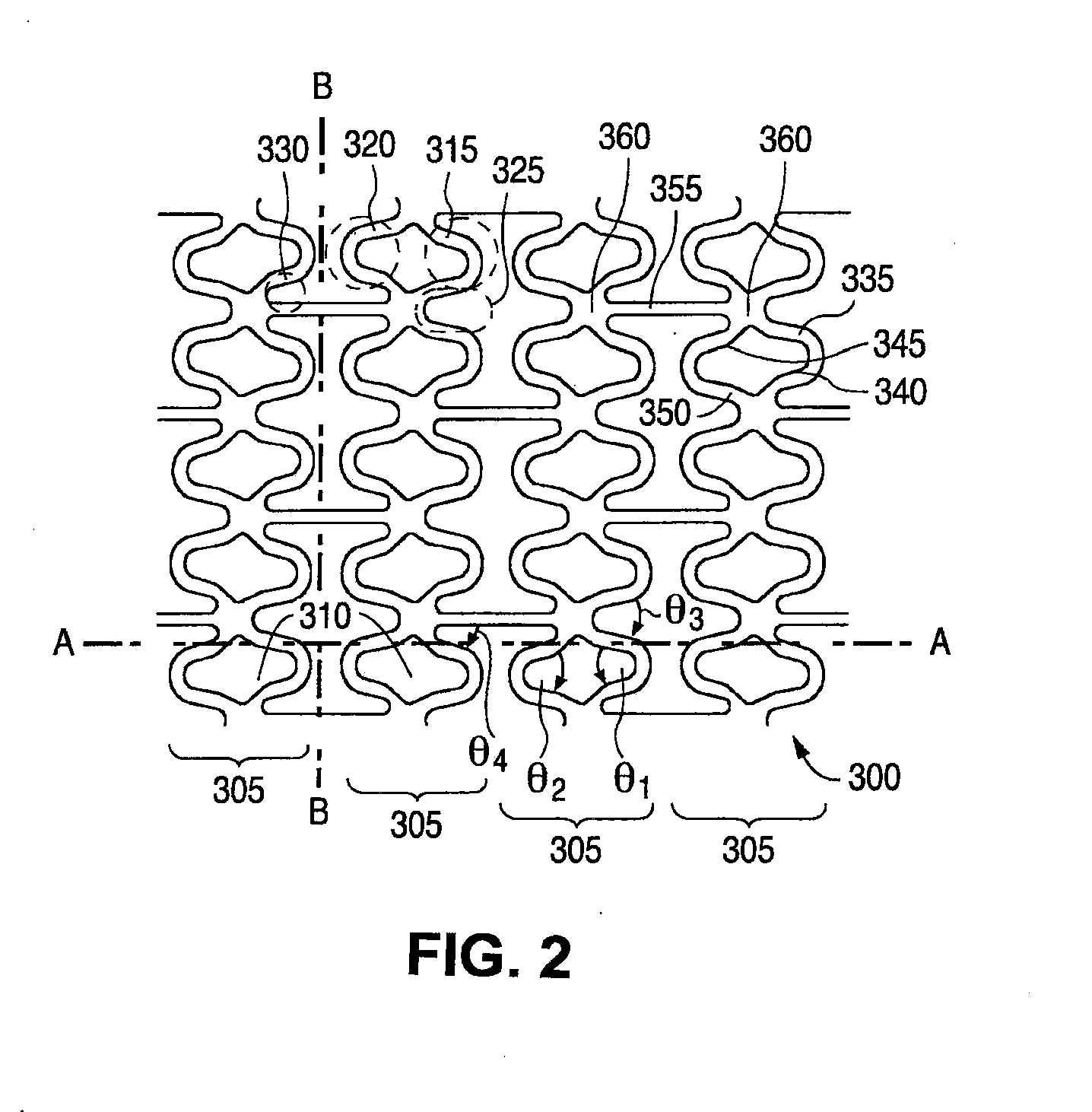

Methods To Increase Fracture Resistance Of A Drug-Eluting Medical Device

InactiveUS20100323091A1Improve fracture resistanceRelieve stress/strainStentsPharmaceutical containersPolymer coatingsMedical device

Owner:ABBOTT CARDIOVASCULAR

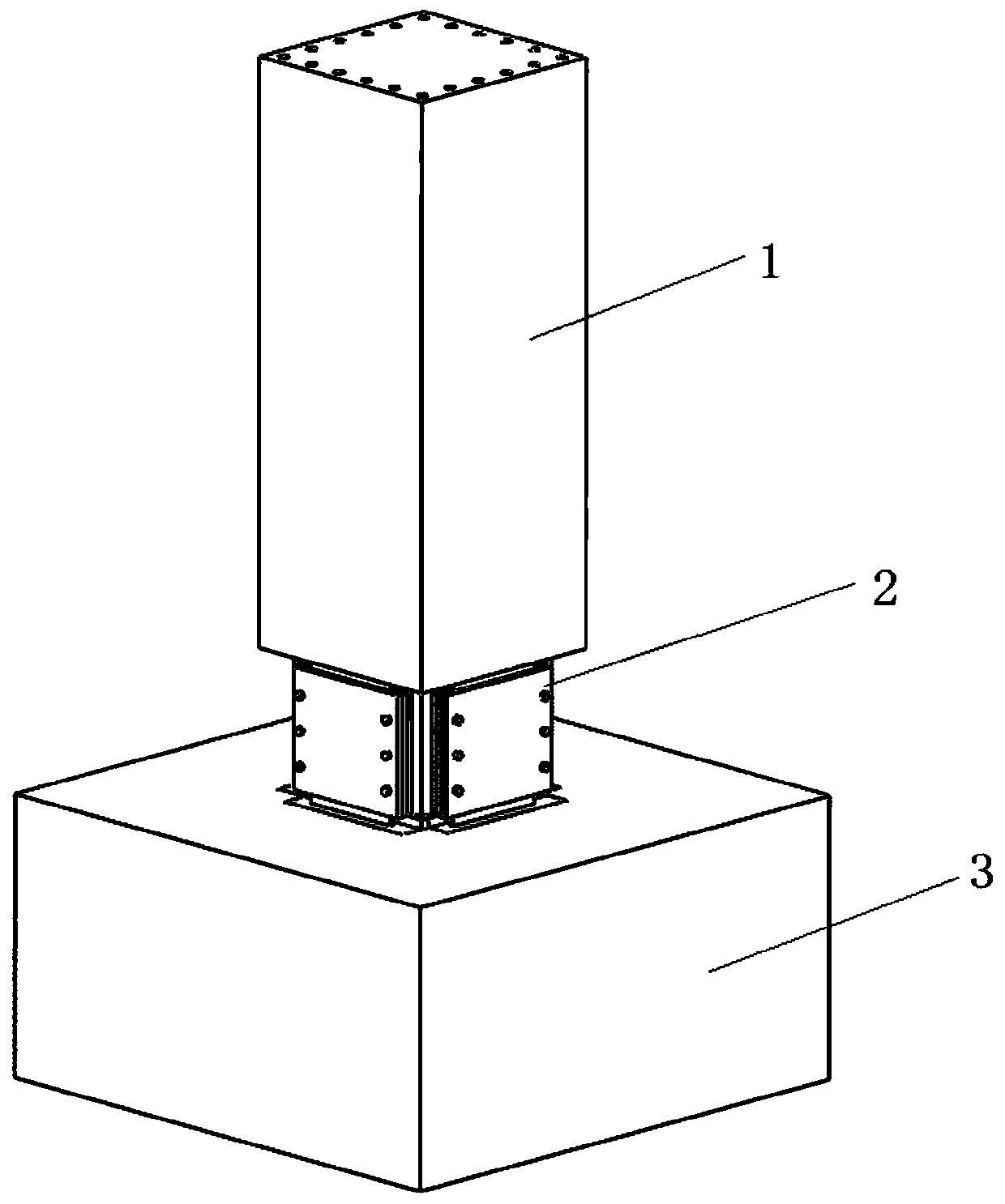

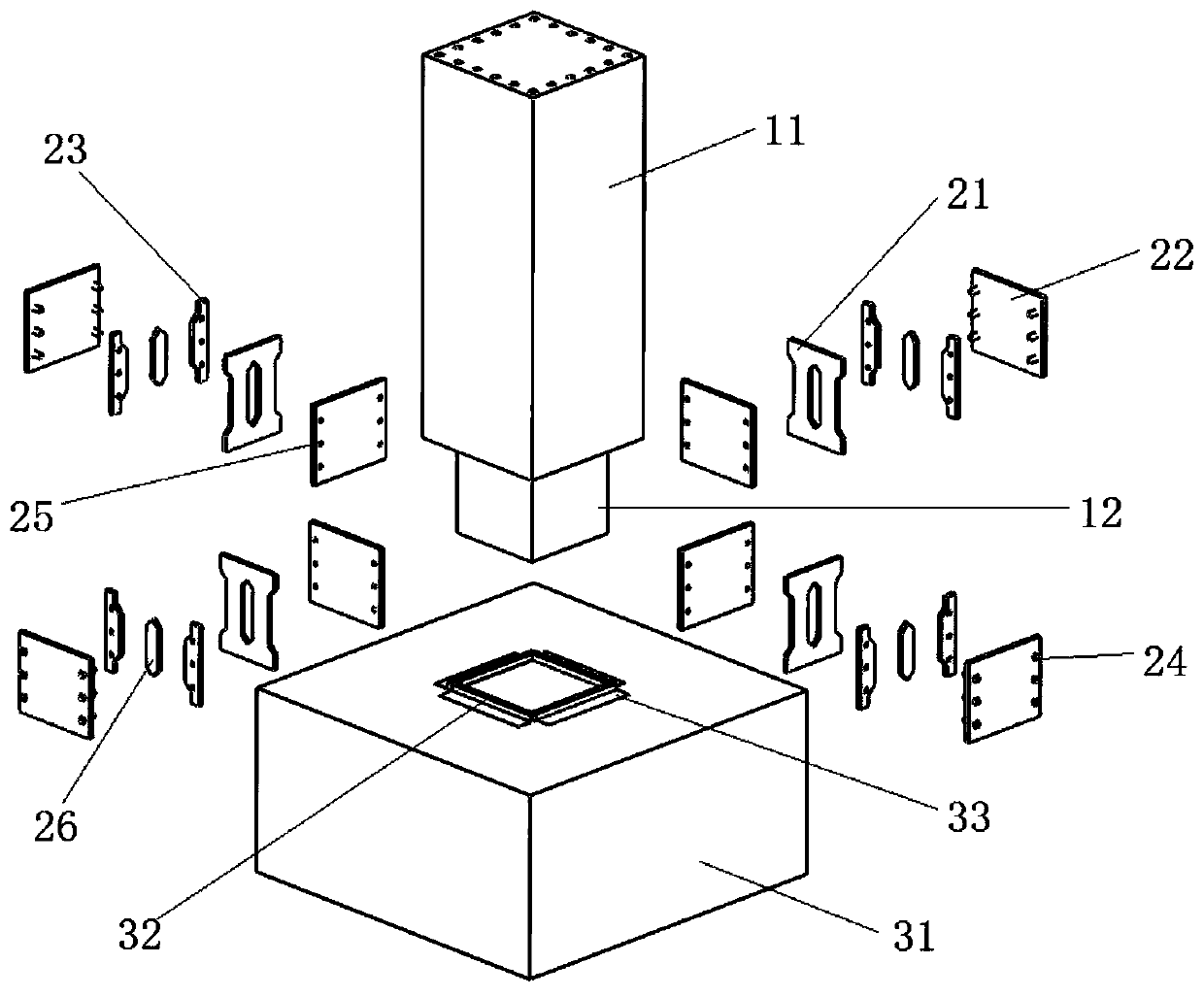

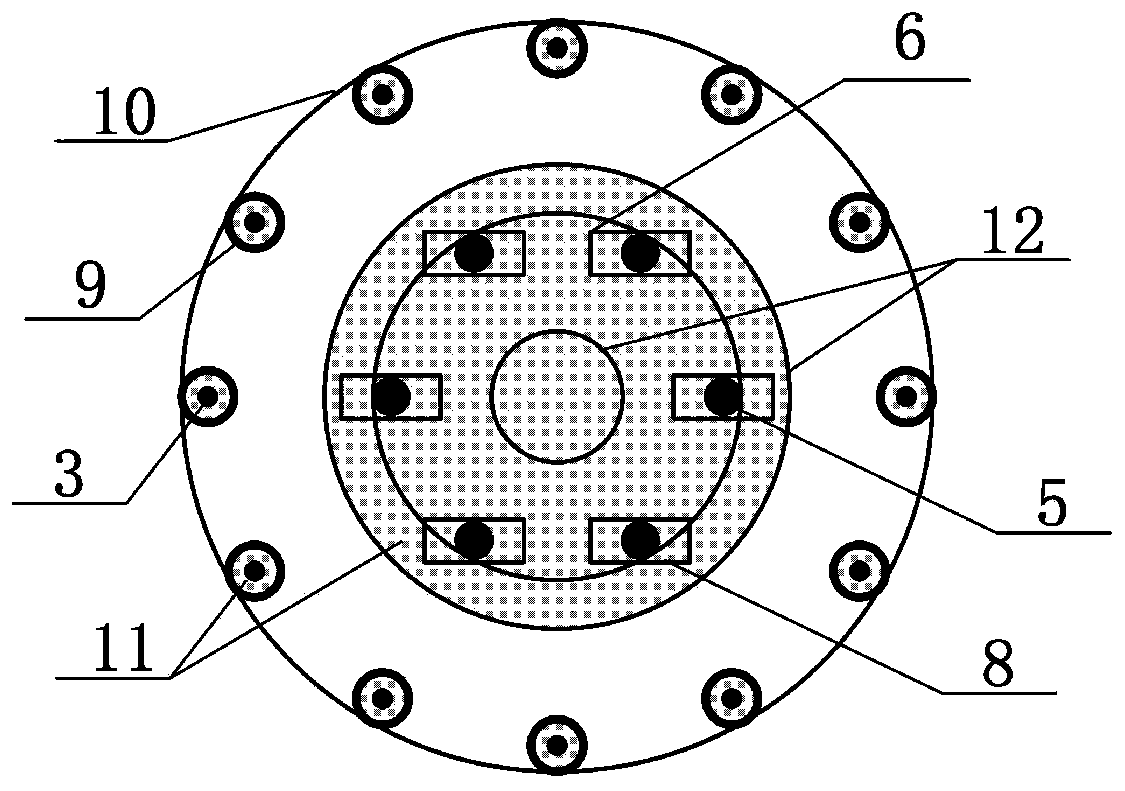

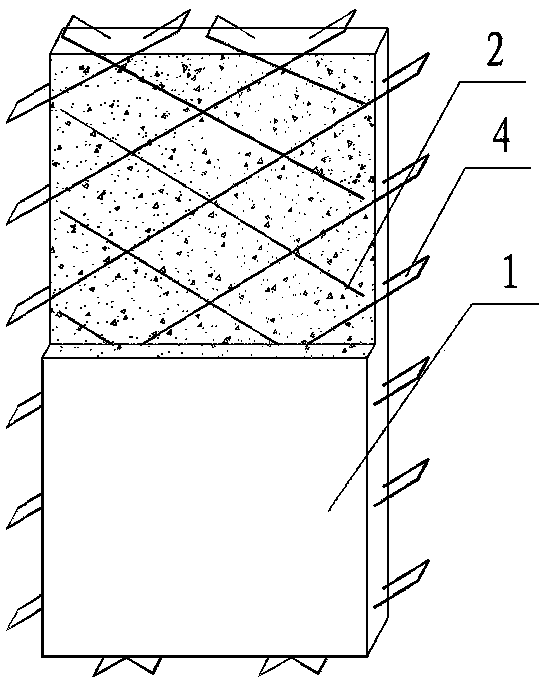

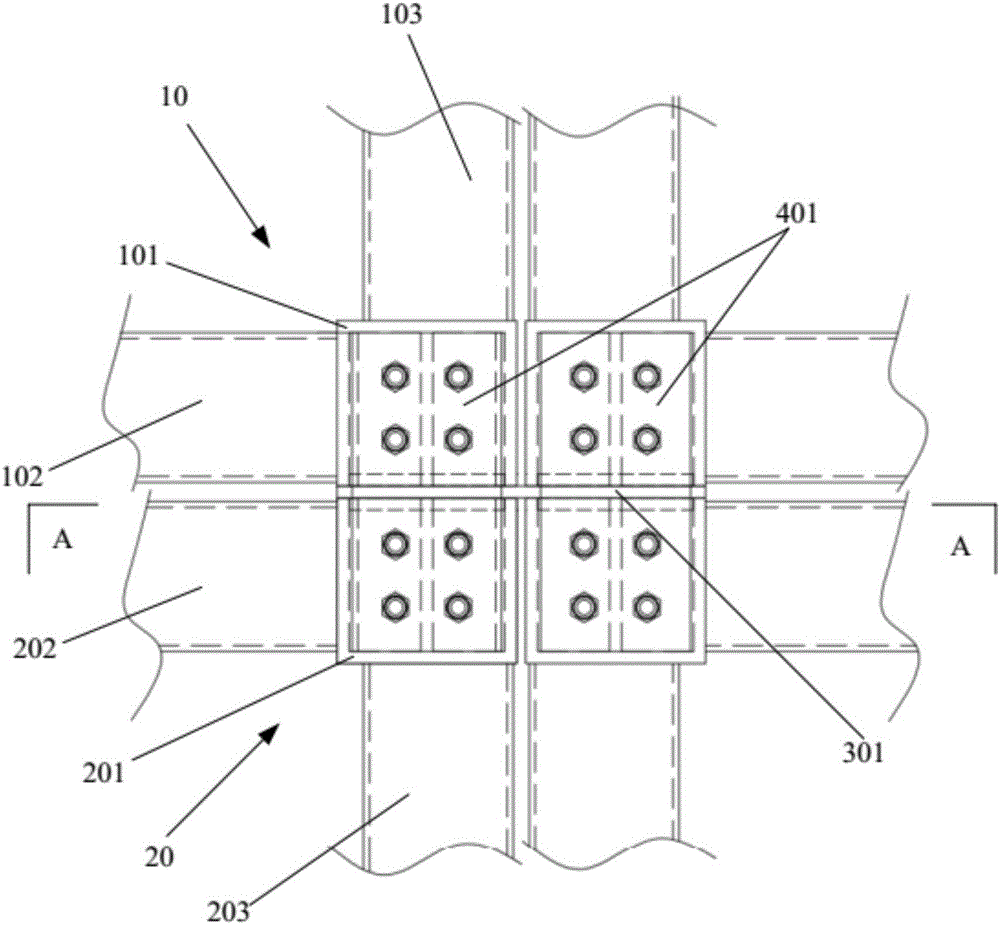

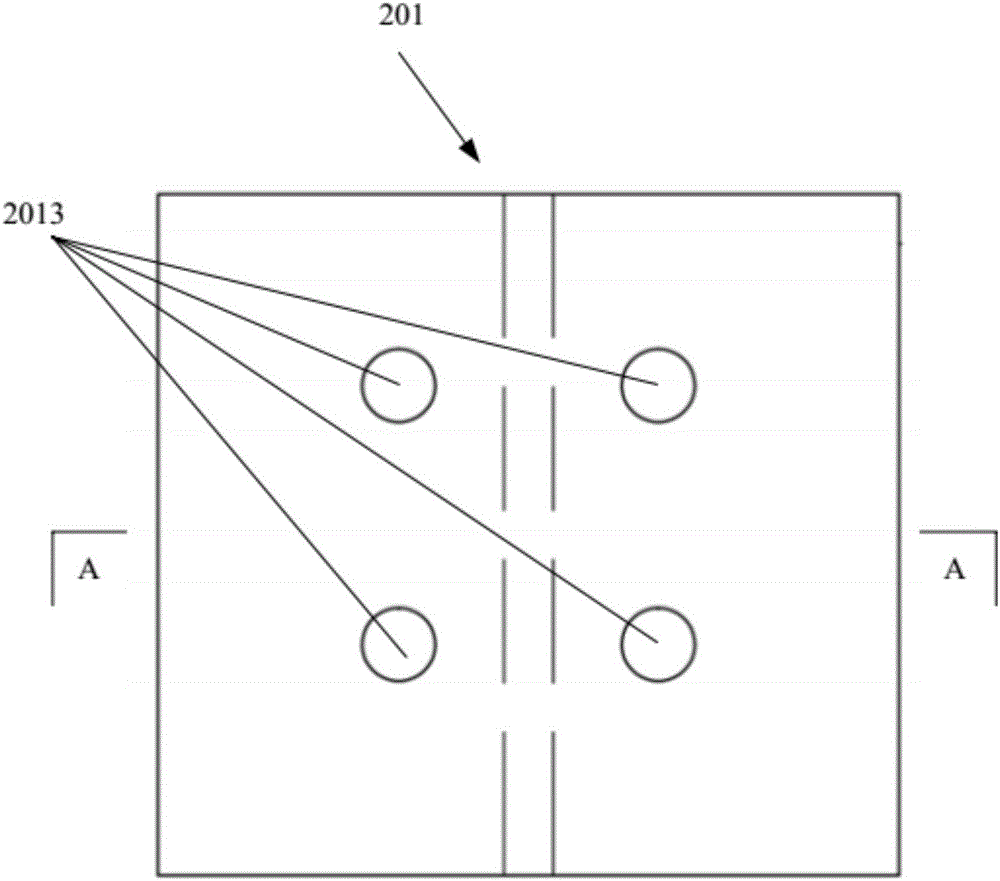

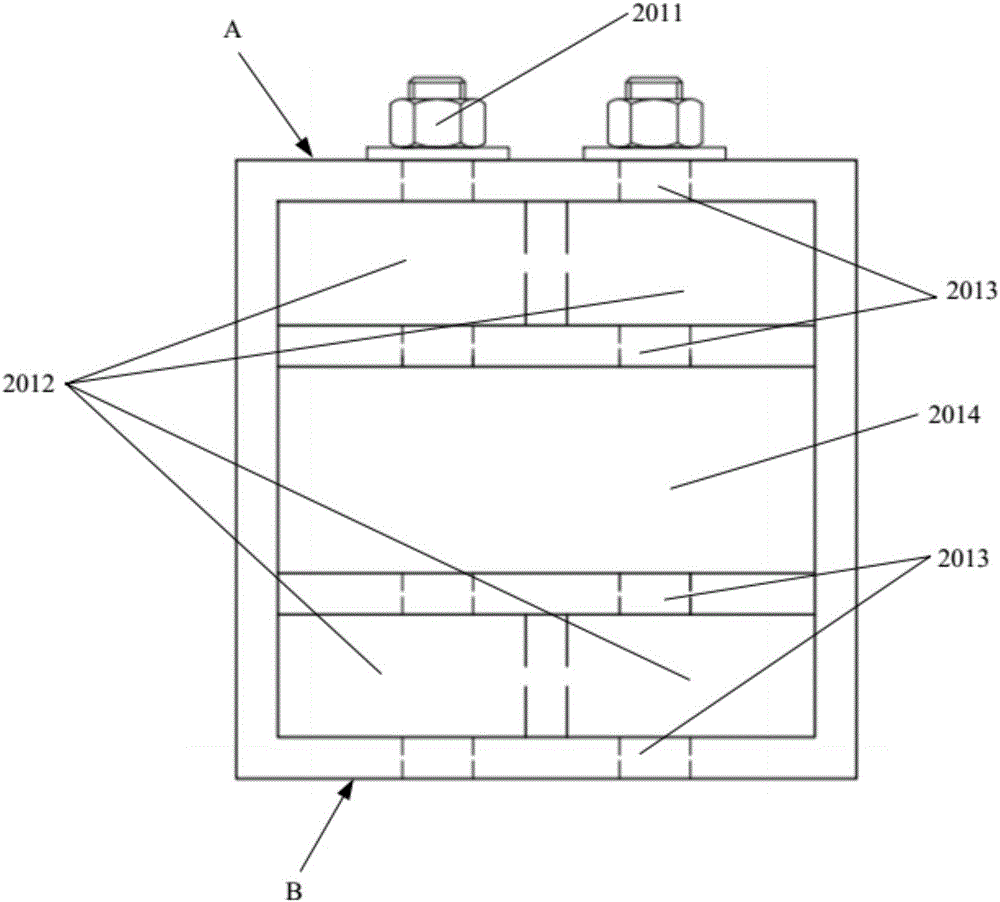

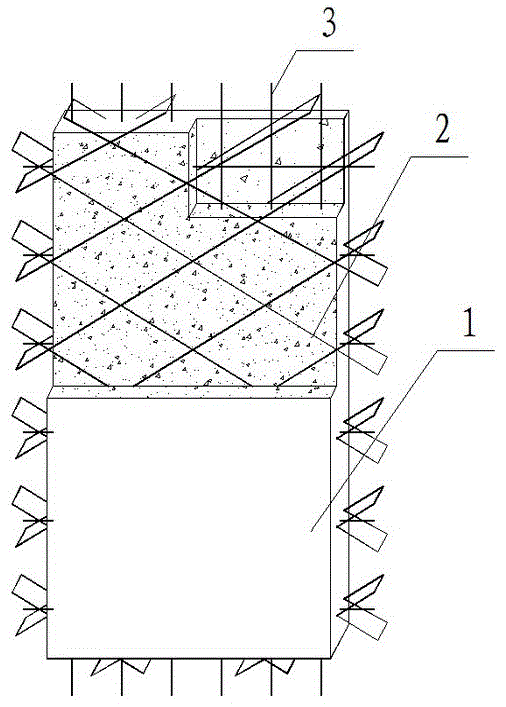

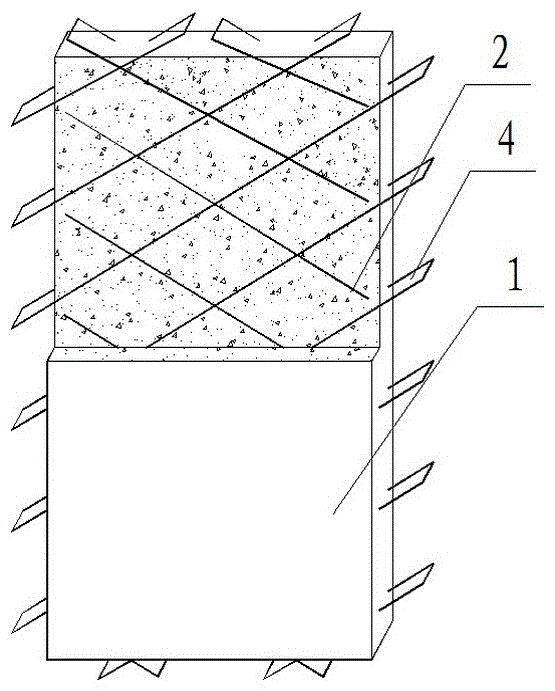

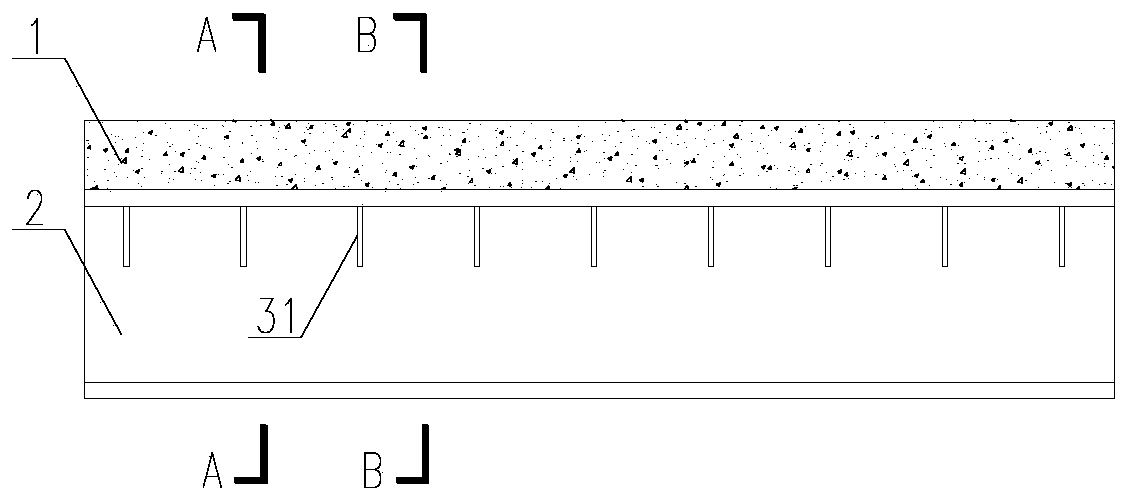

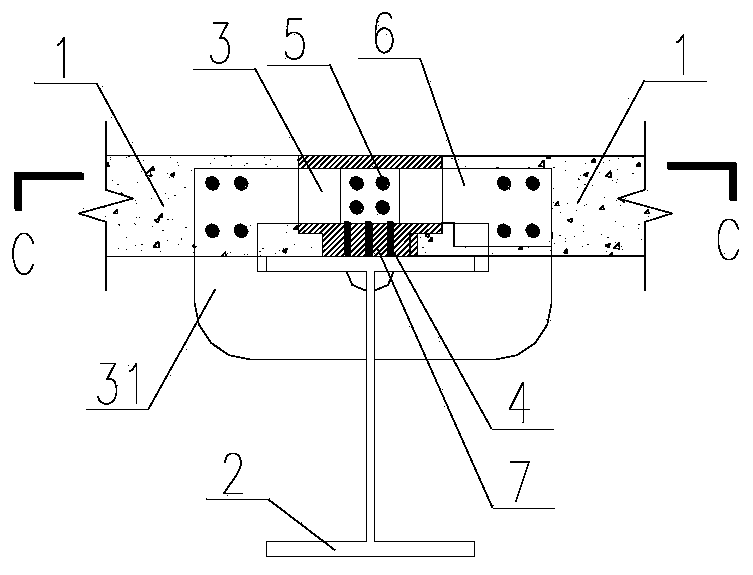

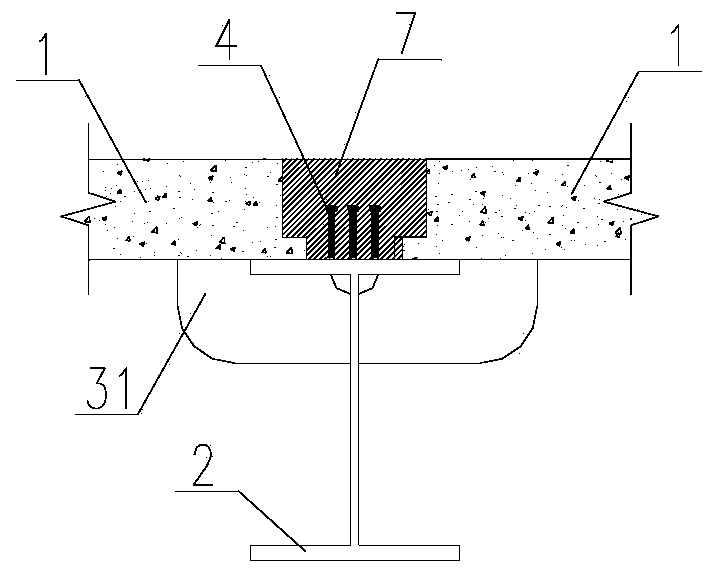

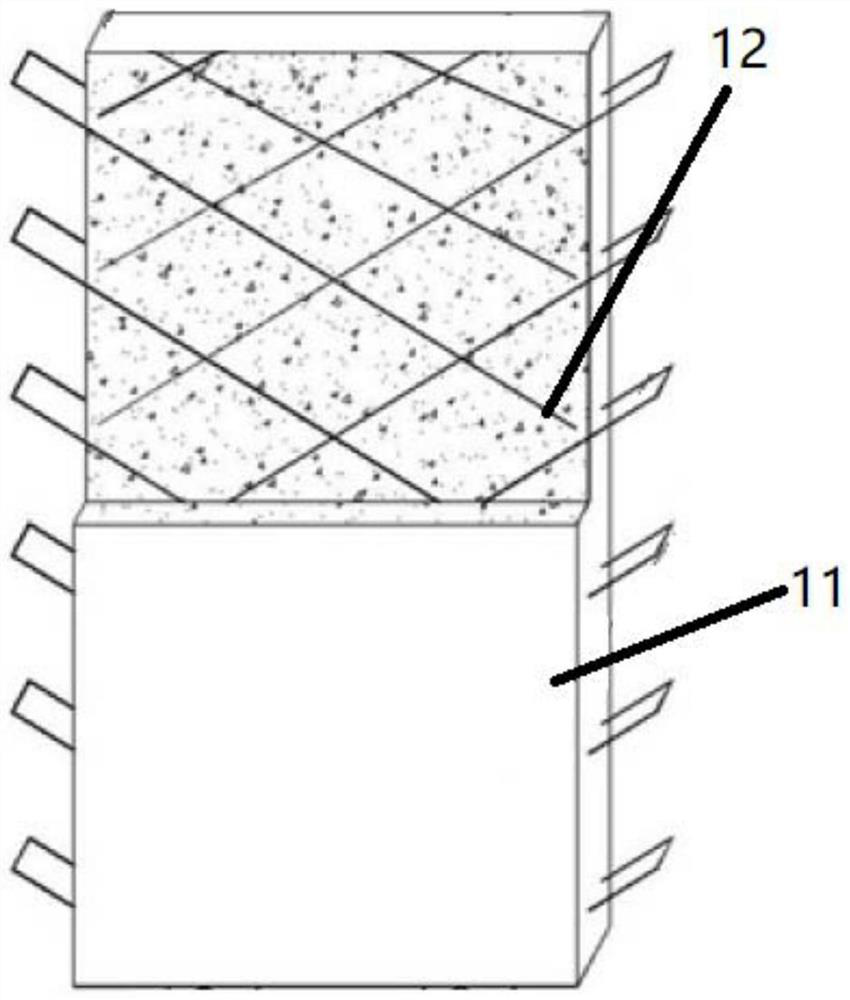

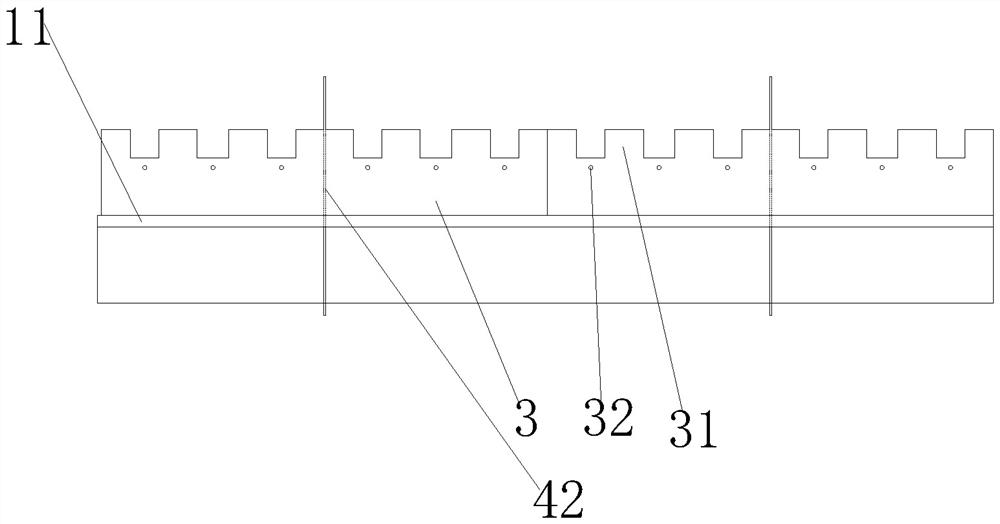

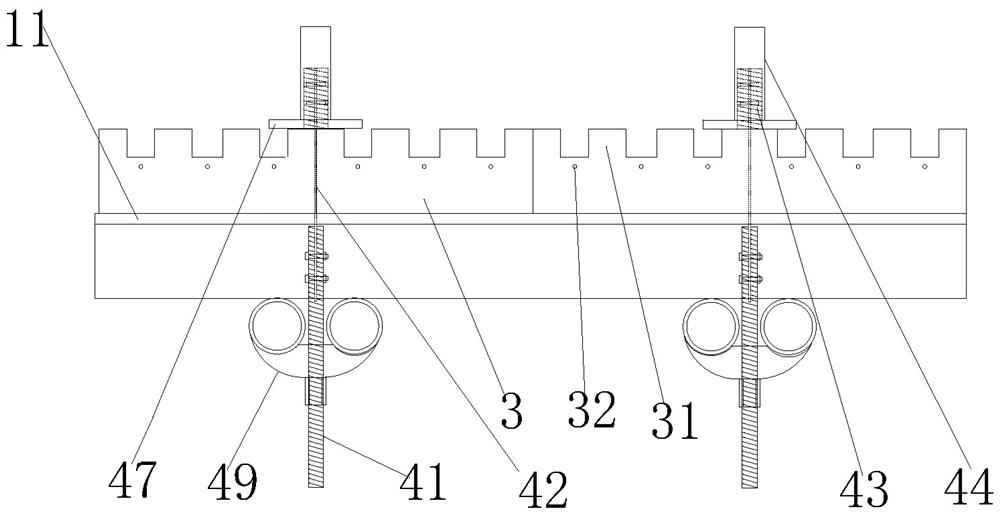

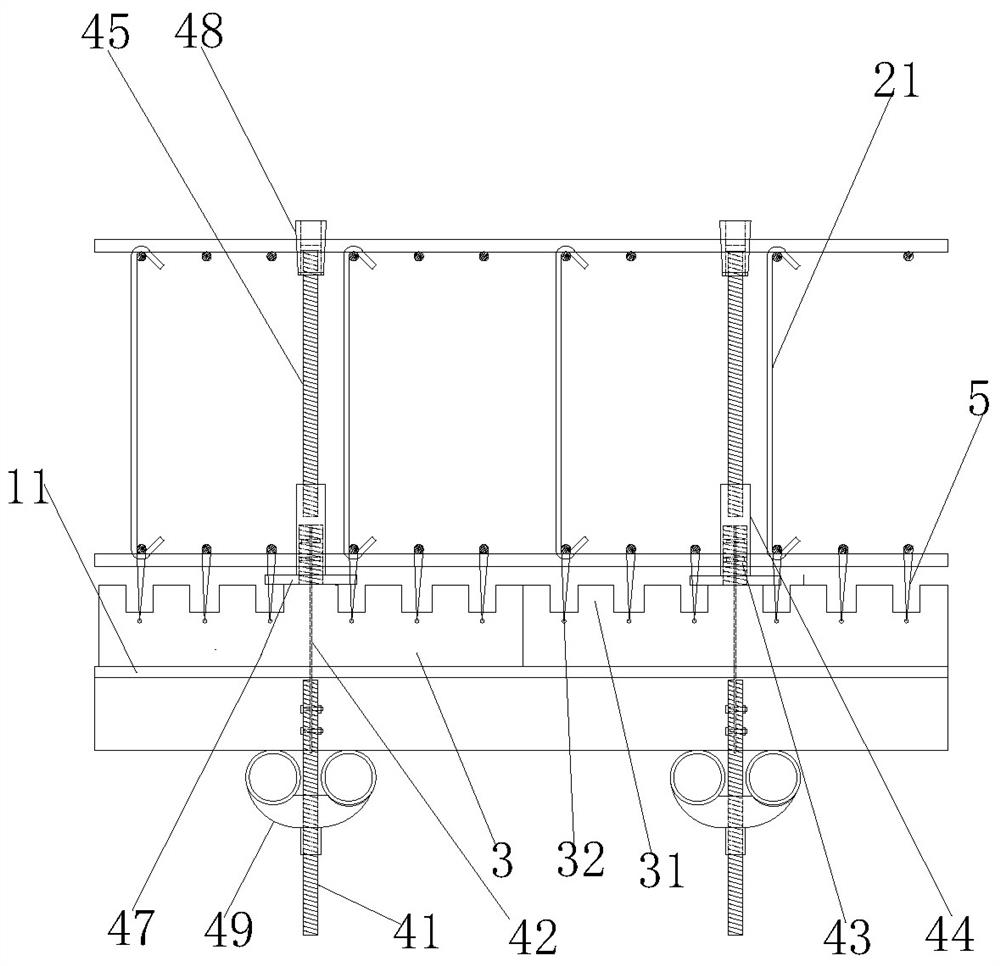

Concrete column base joint containing high-ductility replaceable energy-dissipation connecting assembly

PendingCN110359633AStructural stress division is clearClear division of laborStrutsProtective buildings/sheltersBottom pressurePre embedding

The invention discloses a concrete column base joint containing a high-ductility replaceable energy-dissipation connecting assembly. The concrete column base joint is arranged on the bottom of a rectangular-section column of a concrete structure, and comprises a concrete column, the high-ductility replaceable energy-dissipation connecting assembly and a concrete base, wherein the high-ductility replaceable energy-dissipation connecting assembly is separately welded with the concrete column and a steel connecting block pre-embedded in the concrete base to form a continuous reliable force transmission system. The bottom of the concrete column is equipped with a column bottom reinforcing core column, so that column bottom pressure can be borne under action of an earthquake, and damages are avoided; and the high-ductility replaceable energy-dissipation connecting assembly is mounted on four side surfaces of the column base joint, so that stressed longitudinal bars on the original positionsare replaced, and therefore, hysteretic behavior can be utilized to dissipate earthquake energy during a medium earthquake or a big earthquake, and damages can be controlled inside.

Owner:SOUTHEAST UNIV

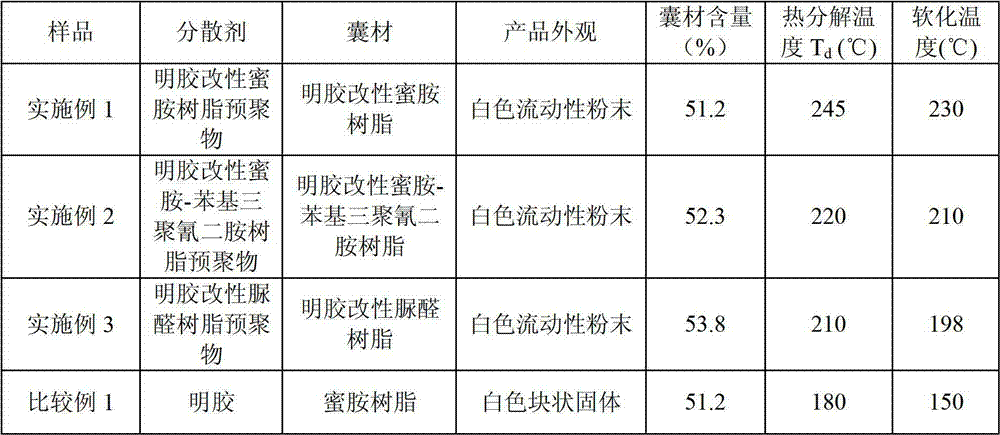

Heatproof microencapsulated essence and its preparation method

InactiveCN102787016ANarrow particle size distributionSmall particle size distributionEssential-oils/perfumesMicroballoon preparationPolymer scienceDecomposition

The invention discloses a heatproof microencapsulated essence used for thermoplastic high polymer materials, and its preparation method. The heatproof microencapsulated essence treats an oil-soluble liquid essence as a capsule core, a gelatin modified amino resin prepolymer as an emulsification dispersant and a gelatin modified amino resin composite material as a wall material. The preparation method of the heatproof microencapsulated essence comprises the processes of prepolymerization, emulsifying dispersion and microcapsule coating. The heat decomposition temperature and the softening temperature of the microencapsulated essence can reach above 200DEG C, mechanical performances comprising the heat resistance, the toughness and the like of the microencapsulated essence are excellent, and the microencapsulated essence has a long-lasting fragrance; and the particle size of the microencapsulated essence is 1-10mum, so the microencapsulated essence can be easily and uniformly dispersed in the high polymer materials.

Owner:HEFEI UNIV OF TECH +1

Fertilizer applicable to sandy saline-alkali land and preparation method of fertilizer

InactiveCN108046891ASimple structureReduce saturated hydraulic conductivityBio-organic fraction processingSewage/sludge fertilisersHydroxyethyl starchSodium Bentonite

The invention discloses a fertilizer applicable to sandy saline-alkali land and a preparation method of the fertilizer. The fertilizer applicable to the sandy saline-alkali land comprises the following components: attapulgite clay, coal fly ash, humic acid, plant straw, municipal solid waste sludge, bentonite, polyacrylamide, carboxymethyl cellulose, hydroxyethyl starch and microbial powder in a weight ratio of (20-30):(20-30):(12-16):(18-22):(4-8):(2-4):(2-4):(1-3):(1-2):(0.5-1.5). The fertilizer applicable to the sandy saline-alkali land provided by the invention can effectively improve thesoil structure of the sandy saline-alkali land, reduce the salinity, reduce the content of sand in the soil, improve the content of nutrients in the soil, improve the compactness of the soil, and canenduringly and effectively improve the sandy saline-alkali land through cooperating with plant cultivation.

Owner:WEIFANG YOURONG IND

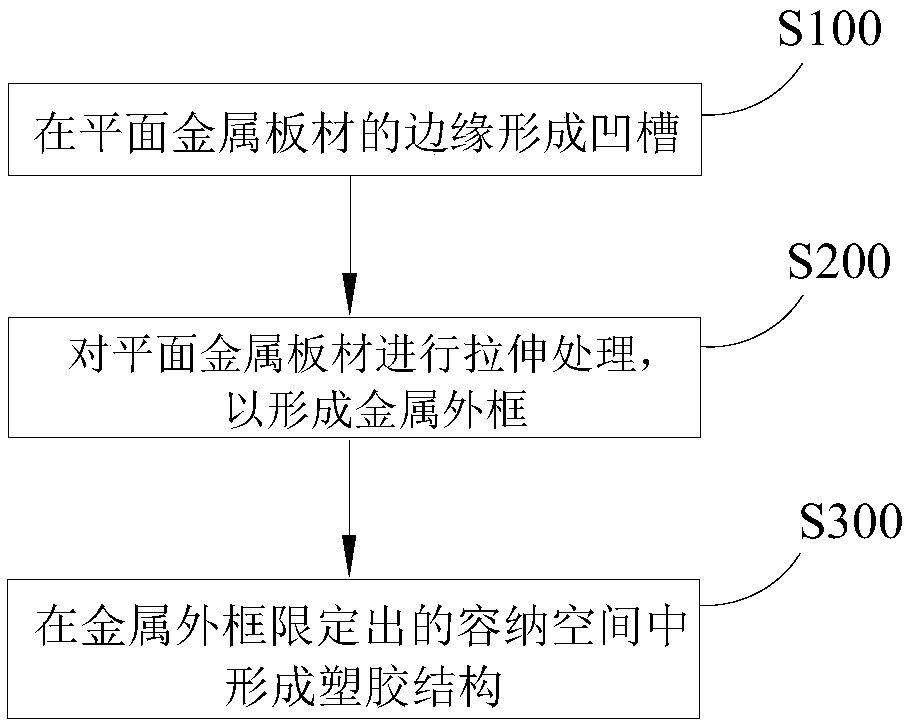

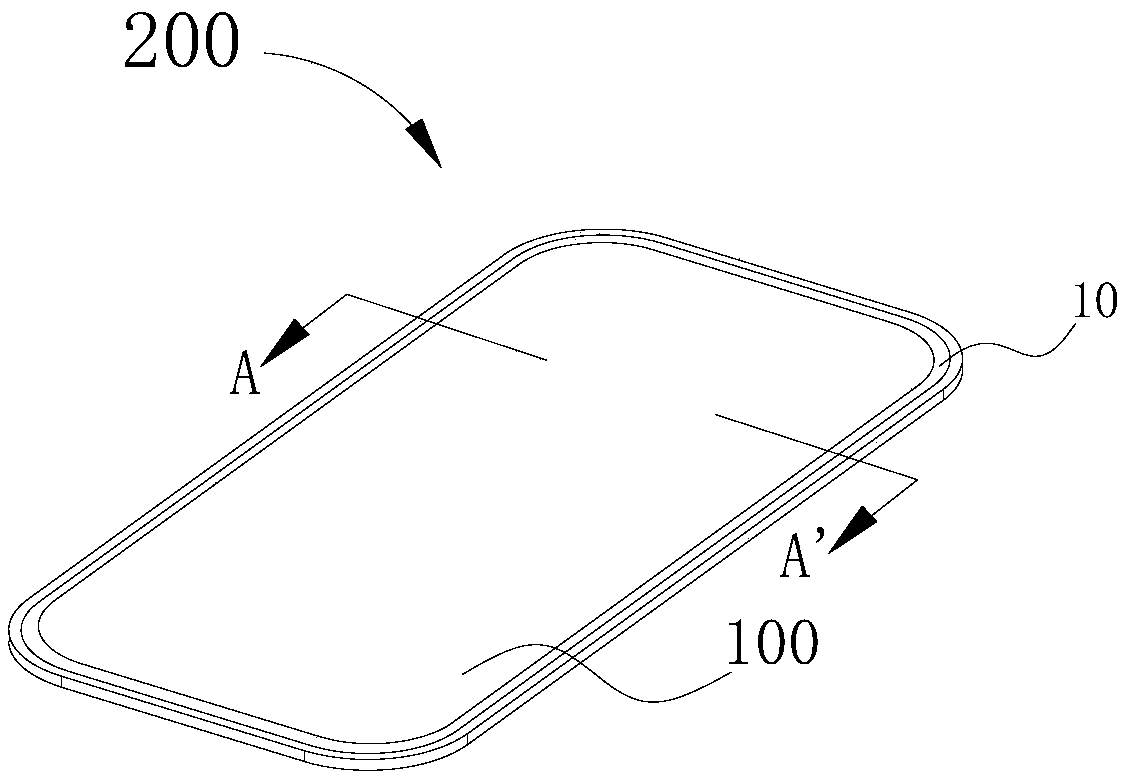

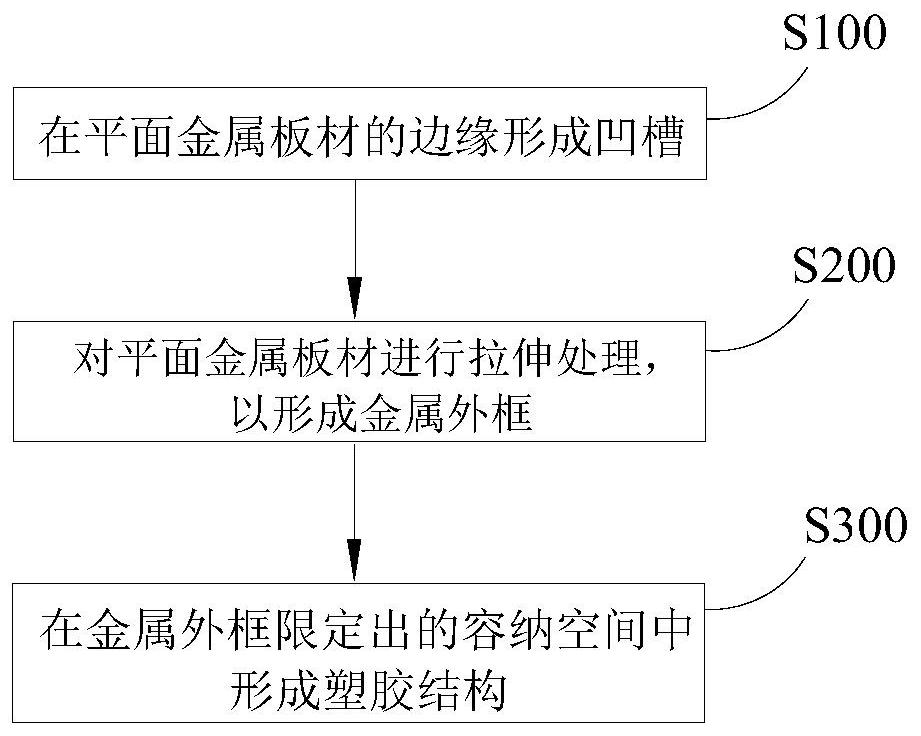

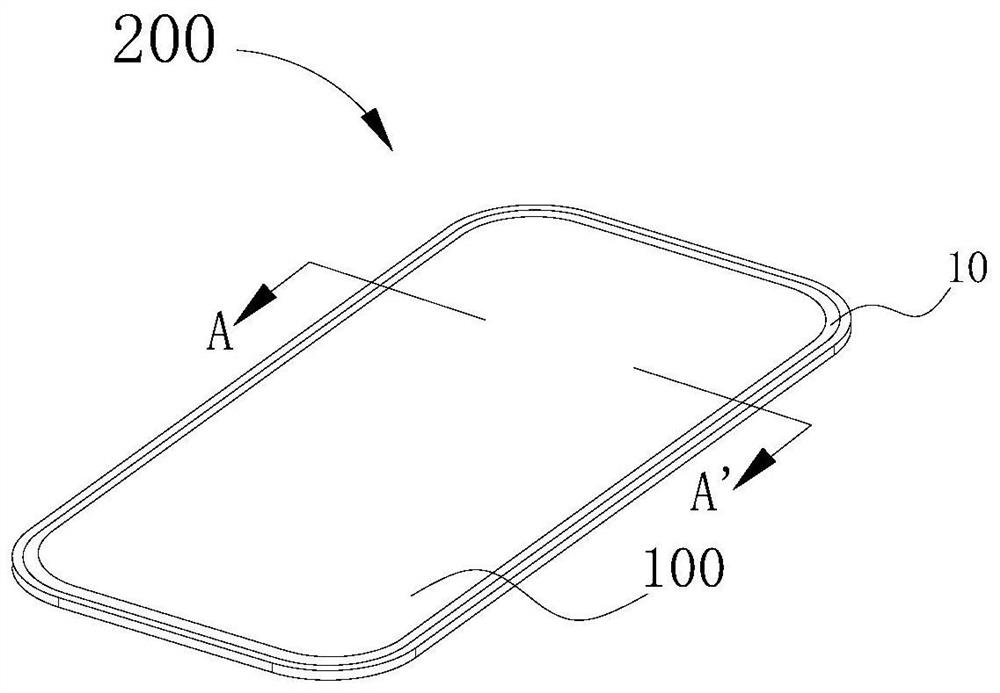

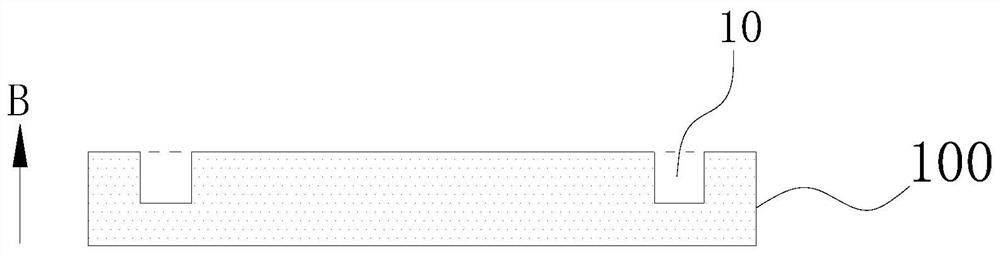

Method for preparing middle frame, middle frame and electronic equipment

ActiveCN108688055AReduce manufacturing costIncrease profitCasings/cabinets/drawers detailsIdentification meansFrame basedEngineering

The invention discloses a method for preparing a middle frame, the middle frame and electronic equipment. The method comprises the following steps: stamping a plane metal panel to form a groove in theedge of the plane metal panel; stretching the plane metal panel with the groove to form a metal outer frame, wherein the metal outer frame is provided with a bottom surface and an annular side framewhich is perpendicular to and surrounds the bottom surface, and the groove is formed in the side wall of the side, facing the bottom surface, of the annular side frame; and carrying out nano injectionmolding treatment on the metal outer frame and defining an accommodating space in the metal outer frame based on the groove to form a plastic structure so as to form the middle frame. Therefore, according to the method, the utilization ratio of raw materials is improved, the production cost is lowered, the processing time is shortened, and the production efficiency is improved.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

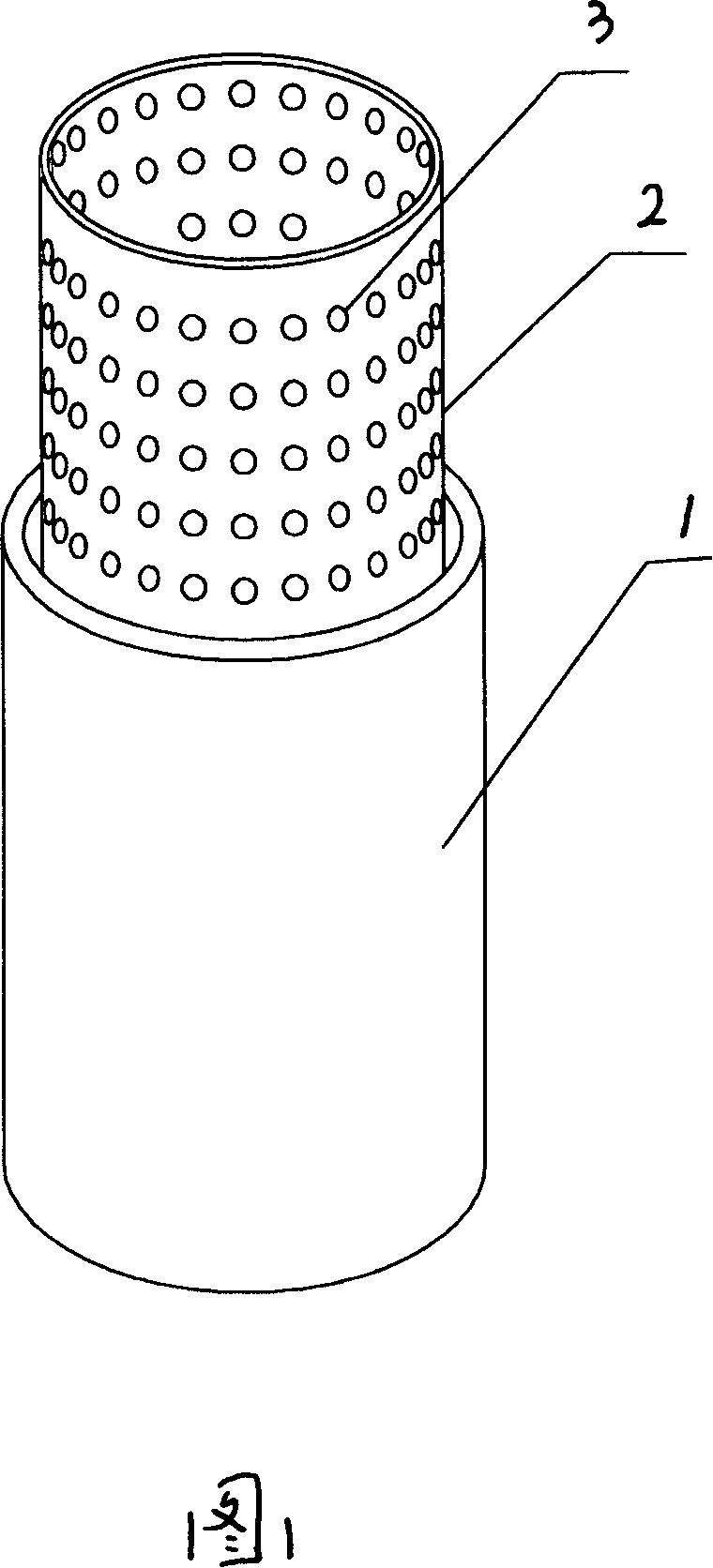

Web frame for concrete organization

InactiveCN101117837AImprove bearing strengthAvoid instabilityBuilding reinforcementsEngineeringHigh torque

The present invention relates to a reinforced frame for concrete structure, and belongs to the construction engineering technology. The present invention is characterized in that a steel tube is arranged and small holes are provided on the tube wall of the steel tube. During the process of pouring concrete column, the concrete is combined with the concrete column via small holes on the tube wall to form an integrated body, therefore, the structure has the functions of high pressure resistance, high shearing resistance, and high torque and vibration resistance, and the present invention has the advantages of simple structure, acceleration of construction progress, saving raw materials and labor forces, being not affected by climate and temperature, being fireproof, being aging and corrosion resistant, and extending service life.

Owner:王加多

Method for planting peanuts and improving soil fertility condition on sandy saline-alkali soil

InactiveCN108029493ASimple structureStrong water absorptionFabaceae cultivationSewage/sludge fertilisersHydroxyethyl starchSodium Bentonite

The invention discloses a method for planting peanuts and improving a soil fertility condition on sandy saline-alkali soil. The method comprises the steps of application of fertilizer which is suitable for the sandy saline-alkali soil, land parcel finishing, seed treatment, sowing, field management and timely harvesting. The fertilizer which is suitable for the sandy saline-alkali soil comprises attapulgite clay, coal ash, humic acid, plant straw, municipal domestic waste sludge, bentonite, polyacrylamide, carboxymethyl cellulose, hydroxyethyl starch and microbial powder with the weight ratioof (20-30):(20-30):(12-16):(18-22):(4-8):(2-4):(2-4):(1-3):(0.5-1.5):(0.5-1.5). According to the method for planting the peanuts and improving the soil fertility condition on the sandy saline-alkali soil, measures such as application of the fertilizer which is suitable for the sandy saline-alkali soil and peanut planting are adopted for improving the saline-alkali soil, the survival rate and yieldof the peanuts are high, the improvement effect on the whole saline-alkali soil is prominent, and the improvement process is environmentally friendly and free of pollution. Therefore, the method is an application technology which is worthy of large-scale popularization.

Owner:WEIFANG YOURONG IND

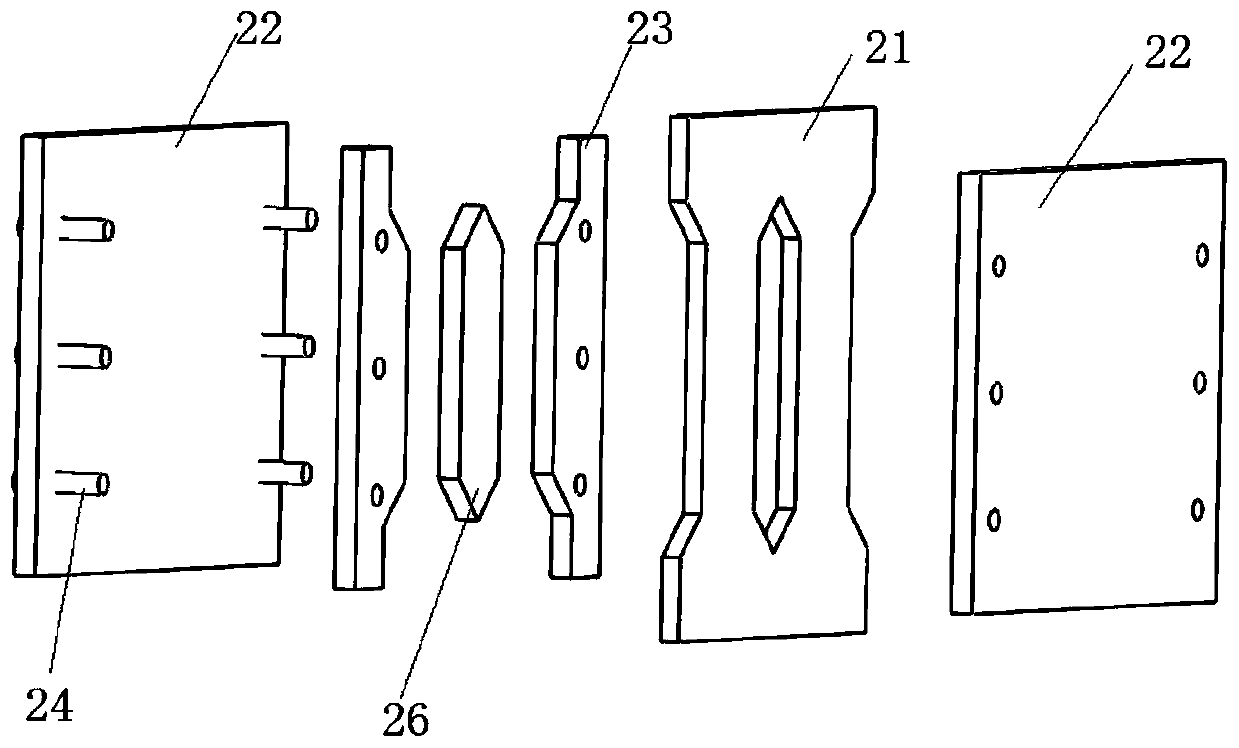

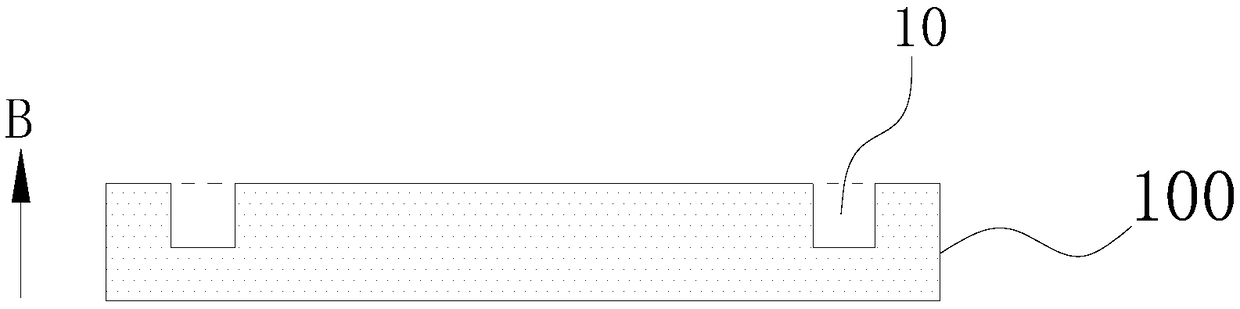

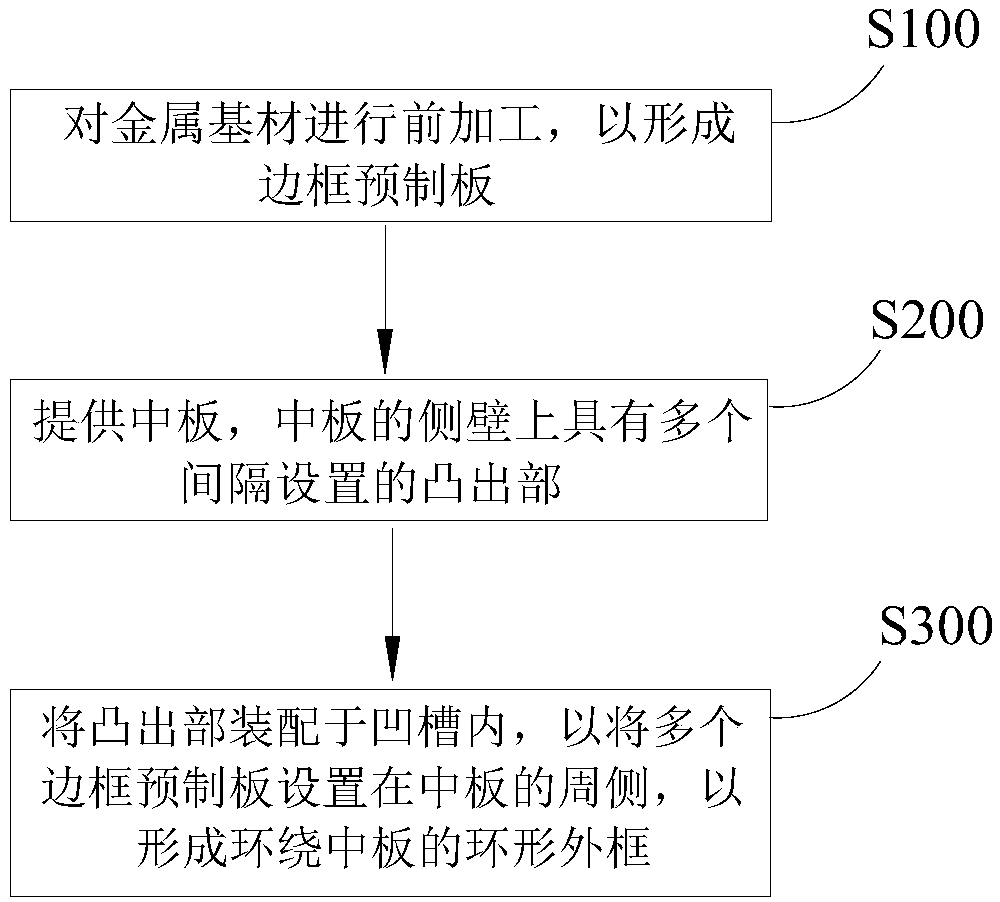

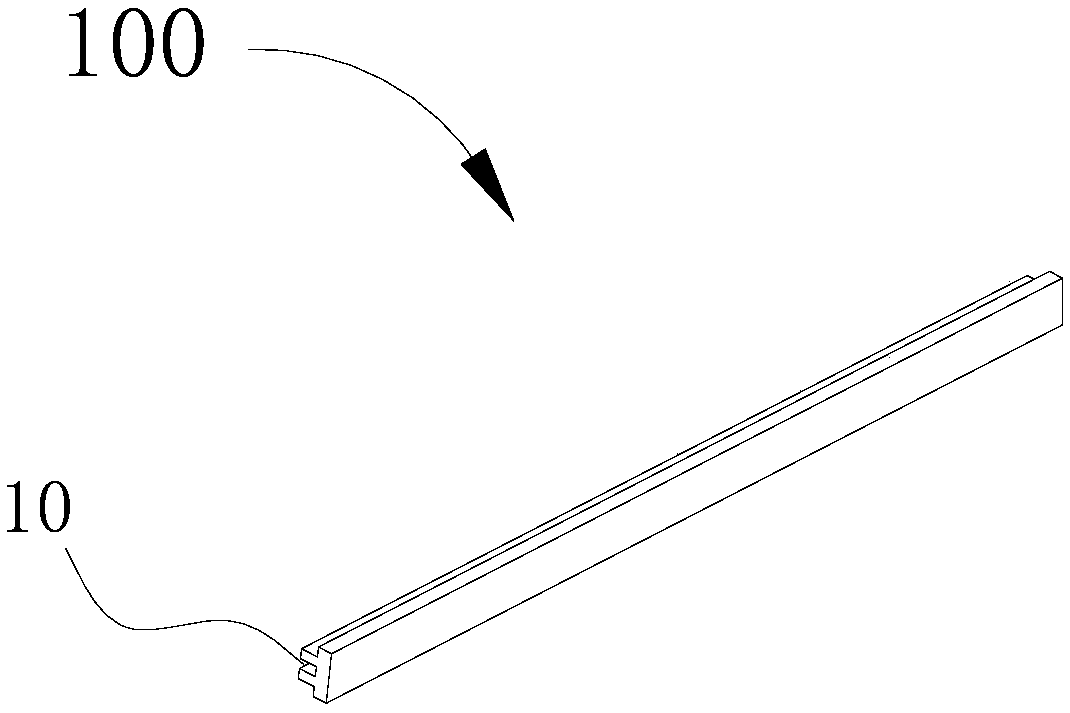

Middle frame and making method thereof, electronic device

InactiveCN108966551AHigh strengthIncrease profitCasings/cabinets/drawers detailsTelephone set constructionsAgricultural engineeringMachining time

The invention discloses a middle frame and a making method thereof, and an electronic device; the method comprises the following steps: preprocessing a metal base material so as to form frame prefabricated slabs, wherein slots are formed on the inner side wall of the frame prefabricated slab; providing a middle plate, and forming a plurality of bumps arranged at intervals on the side wall of the middle plate; assembling the bumps into the slots so as to set the plurality of frame prefabricated slabs around the periphery of the middle plate, and using the plurality of frame prefabricated slabsto form an annular outer frame that encircles the middle plate, thus obtaining the middle frame. The method can effectively improve the raw material utilization rate, can save raw materials, can reduce production costs, can reduce processing time, can improve production efficiency, and can simplify the solidification process.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

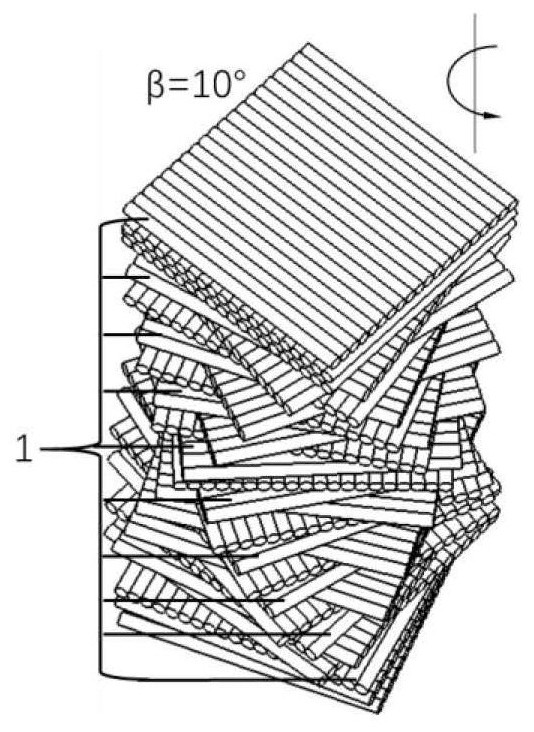

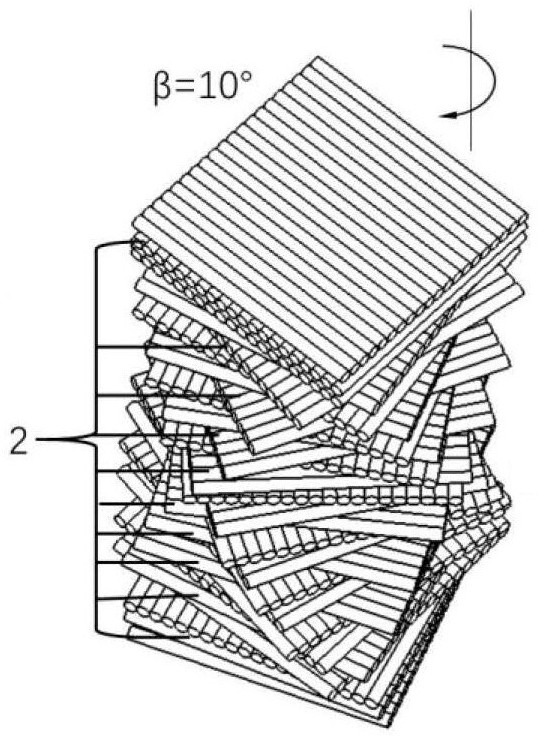

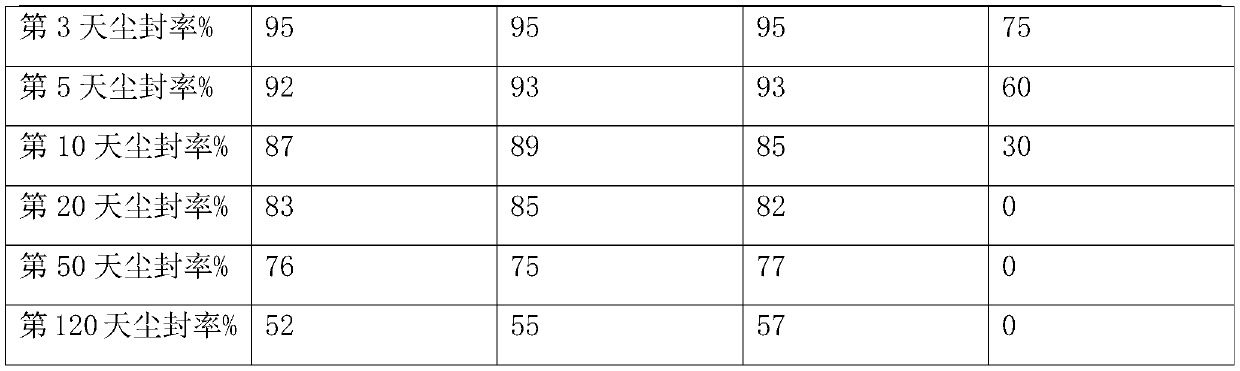

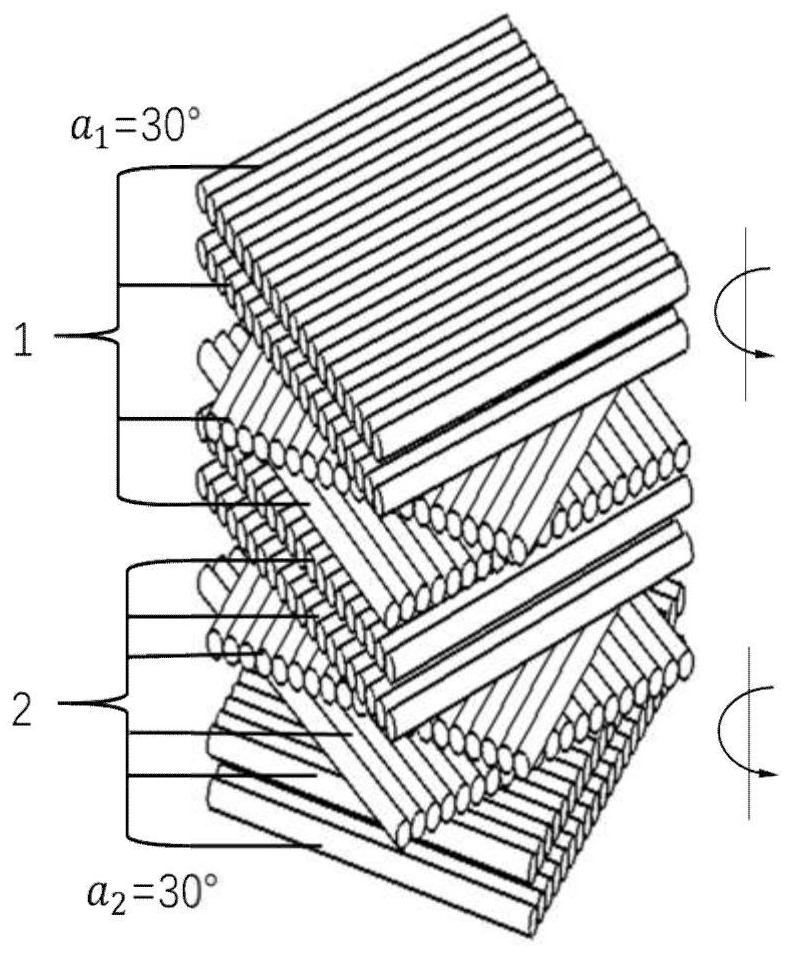

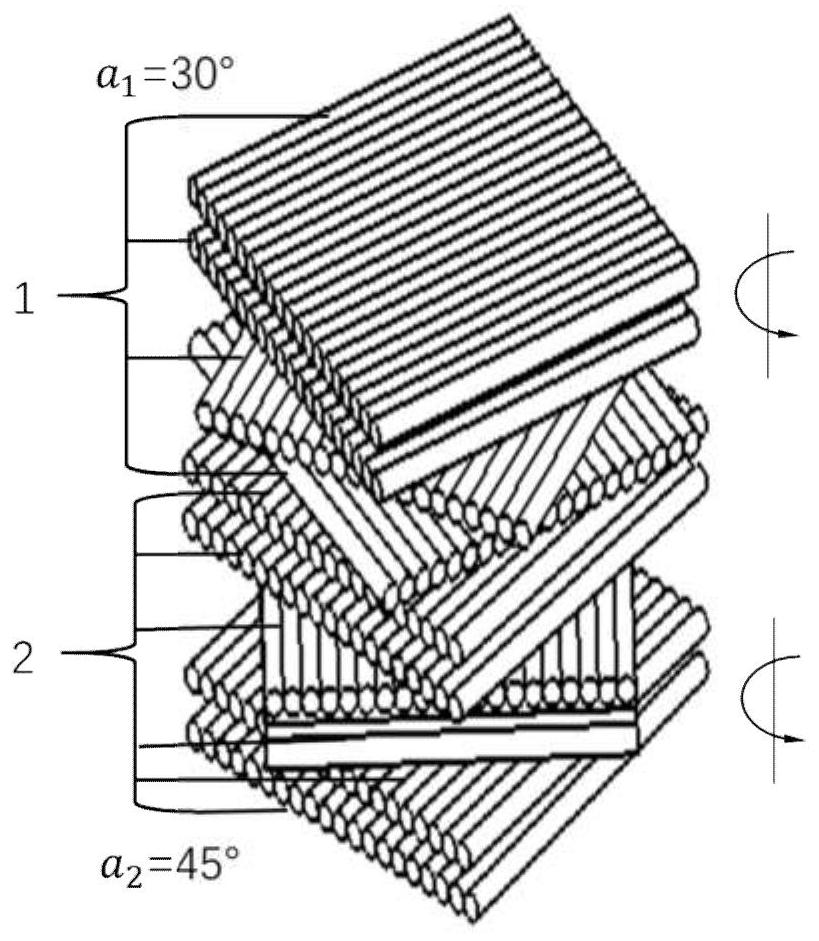

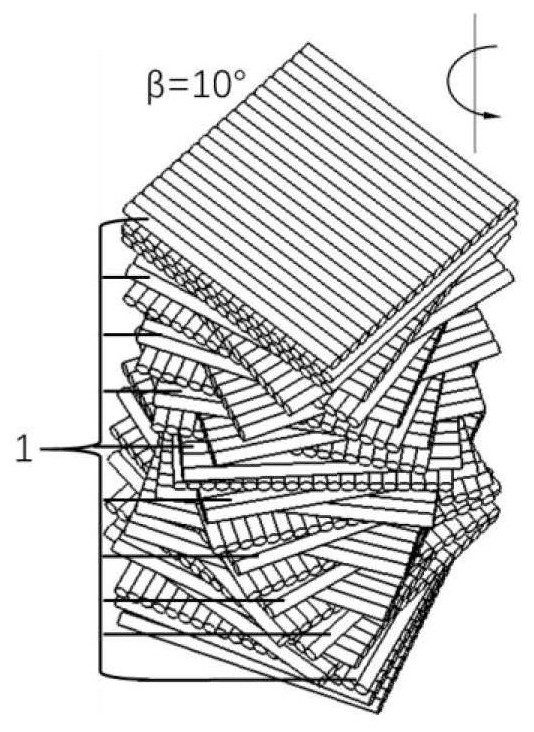

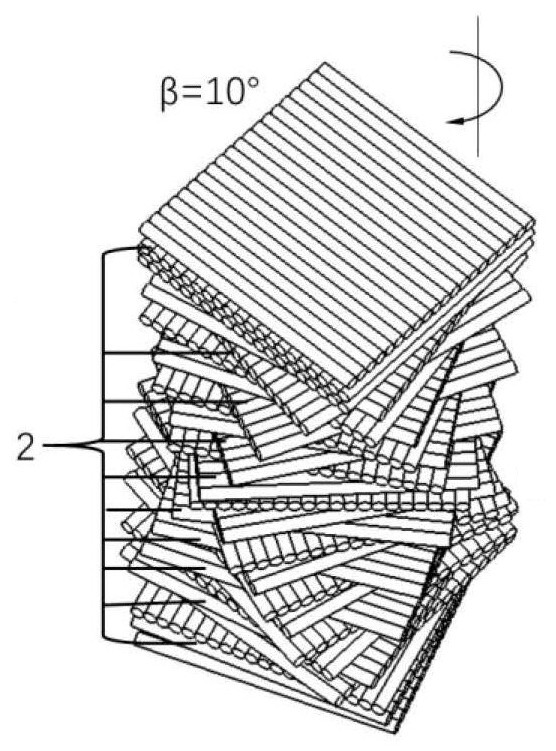

Fiber composite material imitating structure and function of scales of coelacanth

ActiveCN112829413AStrong impact resistanceImpact resistanceSynthetic resin layered productsFibrous compositesCoelacanthus

The invention relates to a fiber composite material imitating the structure and function of scales of coelacanth. According to the fiber composite material, a double-spiral arrangement structure imitating the scales of coelacanth is adopted and is formed by sequentially and alternately laying at least two groups of spiral fiber resin layer structures; in each group of spiral fiber resin layer structure, the fiber resin layers are periodically laid and arranged by sequentially rotating the same rotation angle from top to bottom by taking a center line vertical to the centers of the fiber resin layers as an axis; and the fiber resin layers in each group of spiral fiber resin layer structures are sequentially and alternately laid and stacked. The fiber composite material has the double-spiral fiber arrangement structure imitating the scales of coelacanth, so the fiber layer structures with higher toughness compared with a traditional fiber composite material are obtained, shearing force borne by the fiber composite material can be well resisted, and structural toughness is enhanced.

Owner:JILIN UNIV

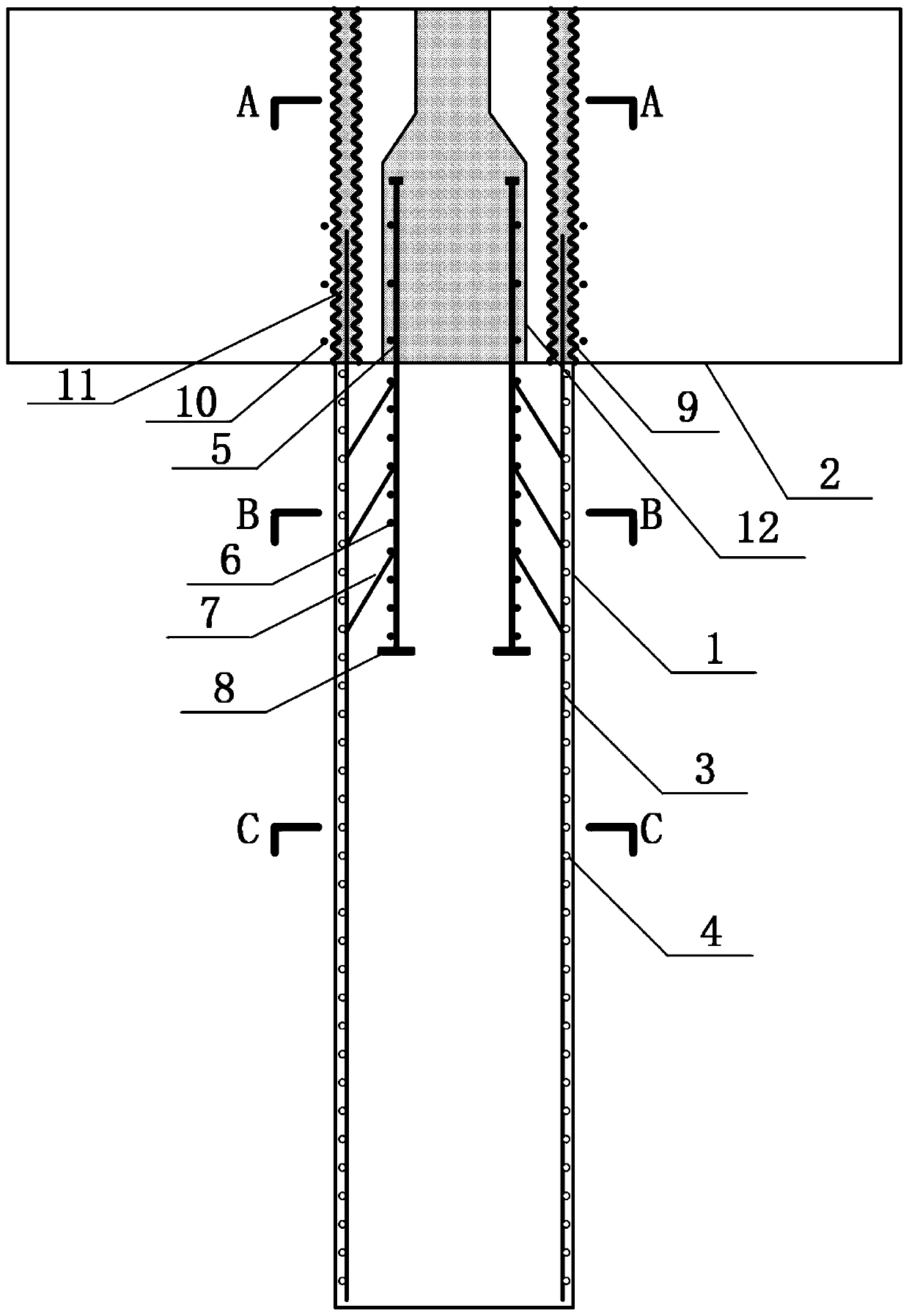

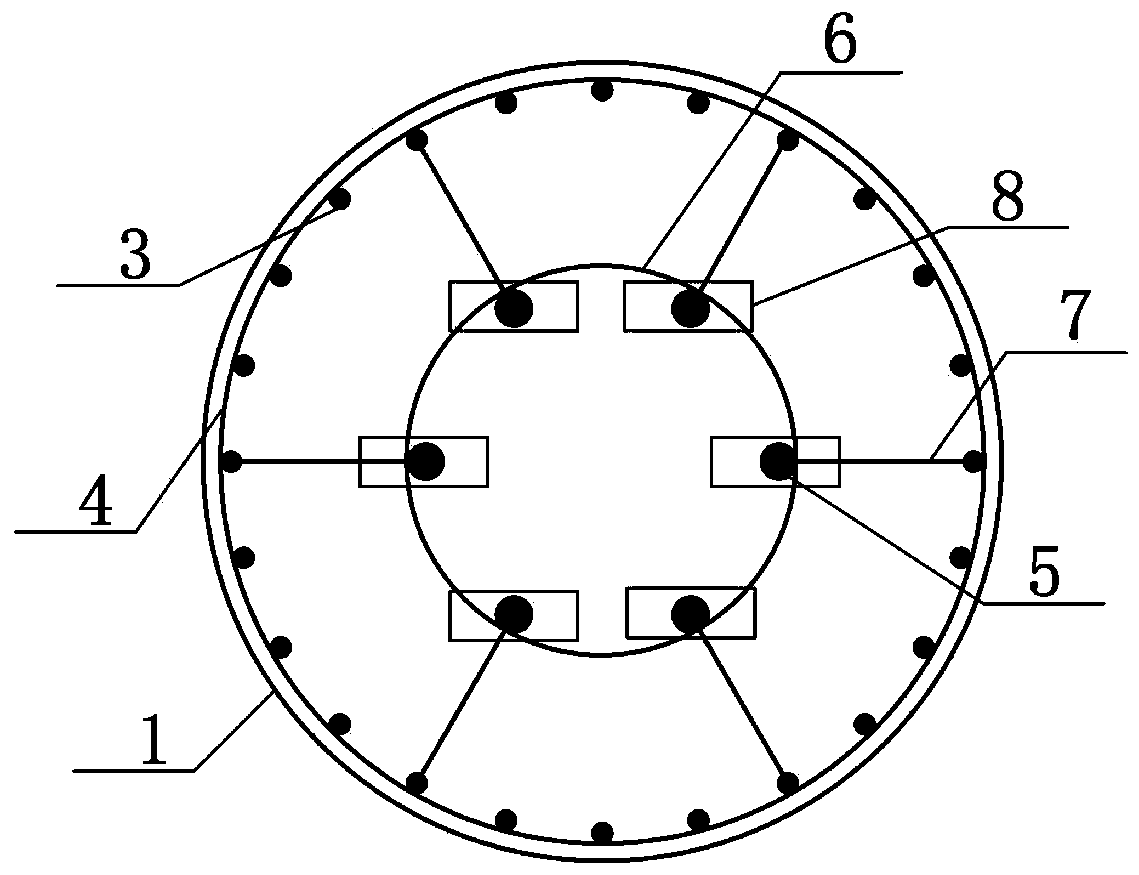

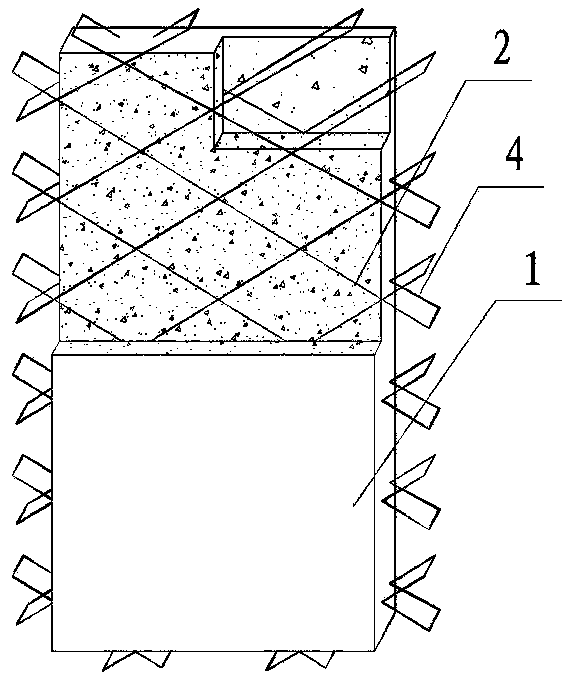

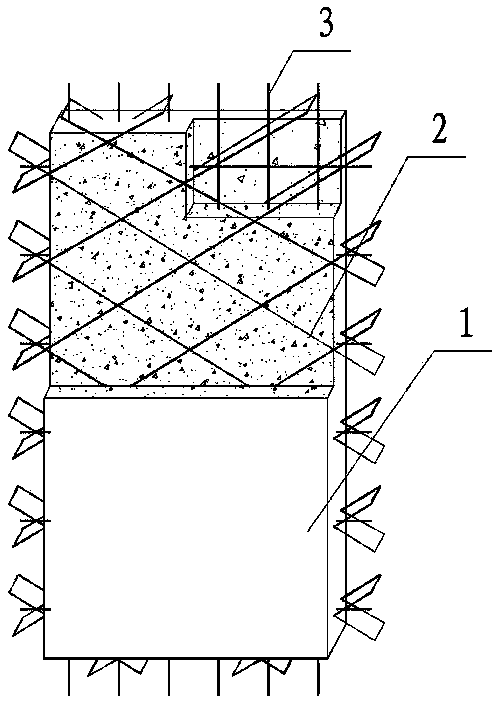

Highly seismic region prefabricated assembled bridge central pier stud-cover beam node pouring connection mode and construction

PendingCN110804944ABuild fastImprove construction fault toleranceBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention discloses a highly seismic region prefabricated assembled bridge central pier stud-cover beam node pouring connection mode and construction and belongs to the field of bridge engineering. The construction comprises a prefabricated pier stud and a prefabricated cover beam. The prefabricated pier stud and the prefabricated cover beam are connected into a bridge pier system through pouring of high-performance materials and splicing. The prefabricated pier stud is composed of a pier stud longitudinal bar, a pier stud stirrup, an overlap-joint large-diameter longitudinal bar, an overlap-joint stirrup and an inclined rebar jointly. The prefabricated cover beam comprises a grouting pipeline, a cover beam construction stirrup and a pouring inserting groove. The splicing quantity of the pier stud longitudinal bar is only a half or much less of the total quantity of longitudinal stressed rebars, and high-performance materials are adopted for pouring splicing. Small damage to a post-earthquake pier stud plastic hinge region is ensured while a large-diameter overlap joint longitudinal bar meets the bridge anti-seismic requirement in a highly seismic region. The bridge building speed can be increased greatly and construction convenience is improved greatly while the bridge anti-seismic requirement in the highly seismic region is met and construction quality is ensured, and a completely novel technical solution can be provided for prefabricated assembled bridge engineering application in the highly seismic region.

Owner:BEIJING UNIV OF TECH

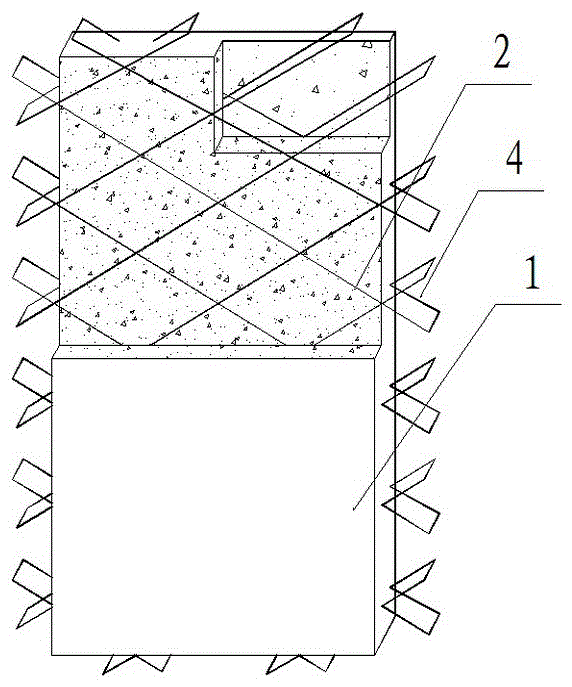

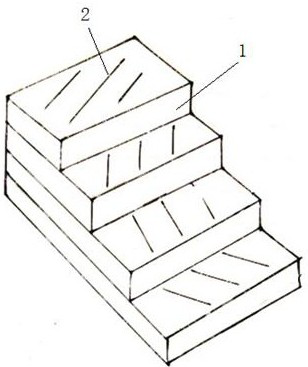

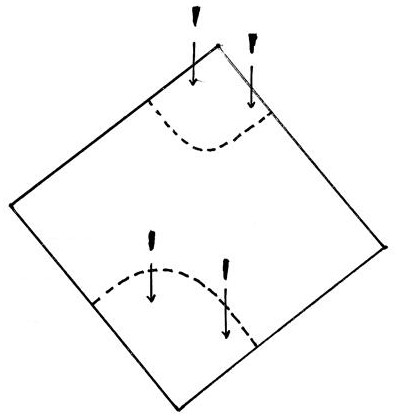

Prefabricated concrete member

The invention relates to a prefabricated concrete member, belonging to the technical field of prefabricated reinforced concrete structures. The prefabricated concrete member is characterized in that bidirectionally crossed distributing bars are distributed in the prefabricated concrete member, wherein included angles between the distributing bars and the sides of the prefabricated concrete member are acute angles or obtuse angles.

Owner:山东艾科福建筑科技有限公司

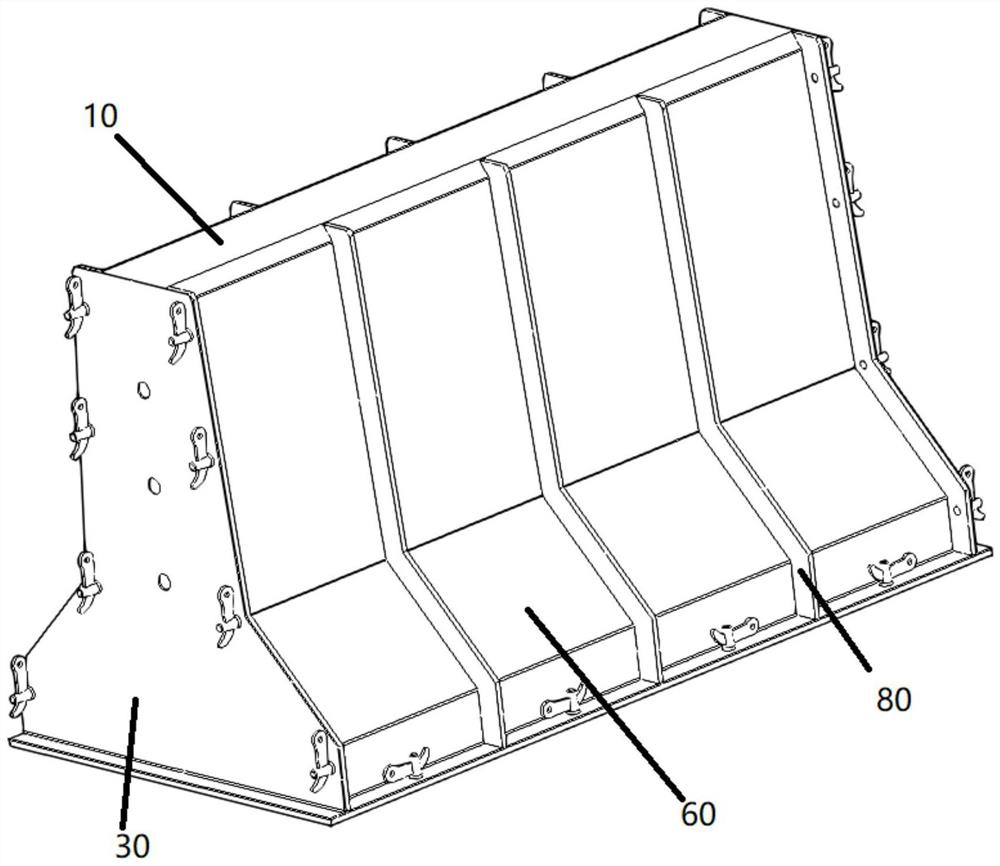

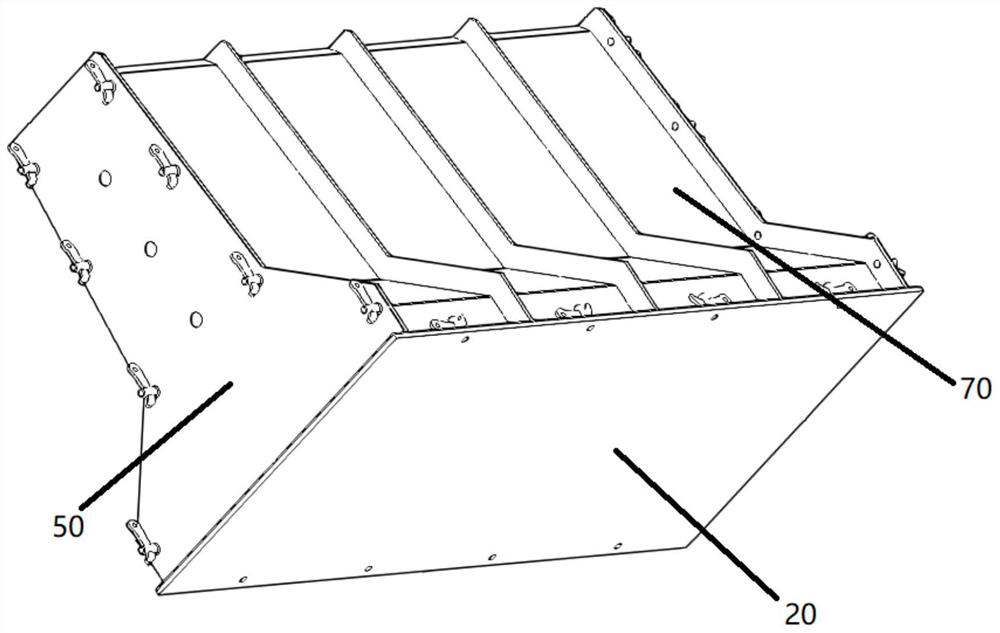

Embedded container house inter-module connection point structure and connection method

InactiveCN106836512AQuick assemblySimplify the assembly processBuilding constructionsComputer moduleEngineering

The invention provides an embedded container house inter-module connection point structure. The embedded container house inter-module connection point structure comprises upper-layer module bottom connecting parts, lower-layer module top connecting parts, inter-module horizontal connecting parts and middle hinge pins, wherein first hinge pin slots are longitudinally formed in the lower-layer module top connecting parts, first bolt holes horizontally penetrate through and are formed in the lower-layer module top connecting parts, and first nuts are welded in the positions, corresponding to the first bolt holes, of one side of the inner wall of each lower-layer module top connecting part; second hinge pin holes are longitudinally formed in the upper-layer module bottom connecting parts, second bolt holes horizontally penetrate through and are formed in the upper-layer module bottom connecting parts, and second nuts are welded in the positions, corresponding to the second bolt holes, of one side of the inner wall of each upper-layer module bottom connecting part; the middle hinge pins are inserted into the first hinge pin slots and the second hinge pin slots to connect the upper-layer module bottom connecting parts and the lower-layer module top connecting parts. By means of the embedded container house inter-module connection point structure, decoration in container modules is not damaged while assembly can be realized, and a container house can be assembled really rapidly and conveniently.

Owner:GUOZHU HABITAT ENG CONSULTANTS +1

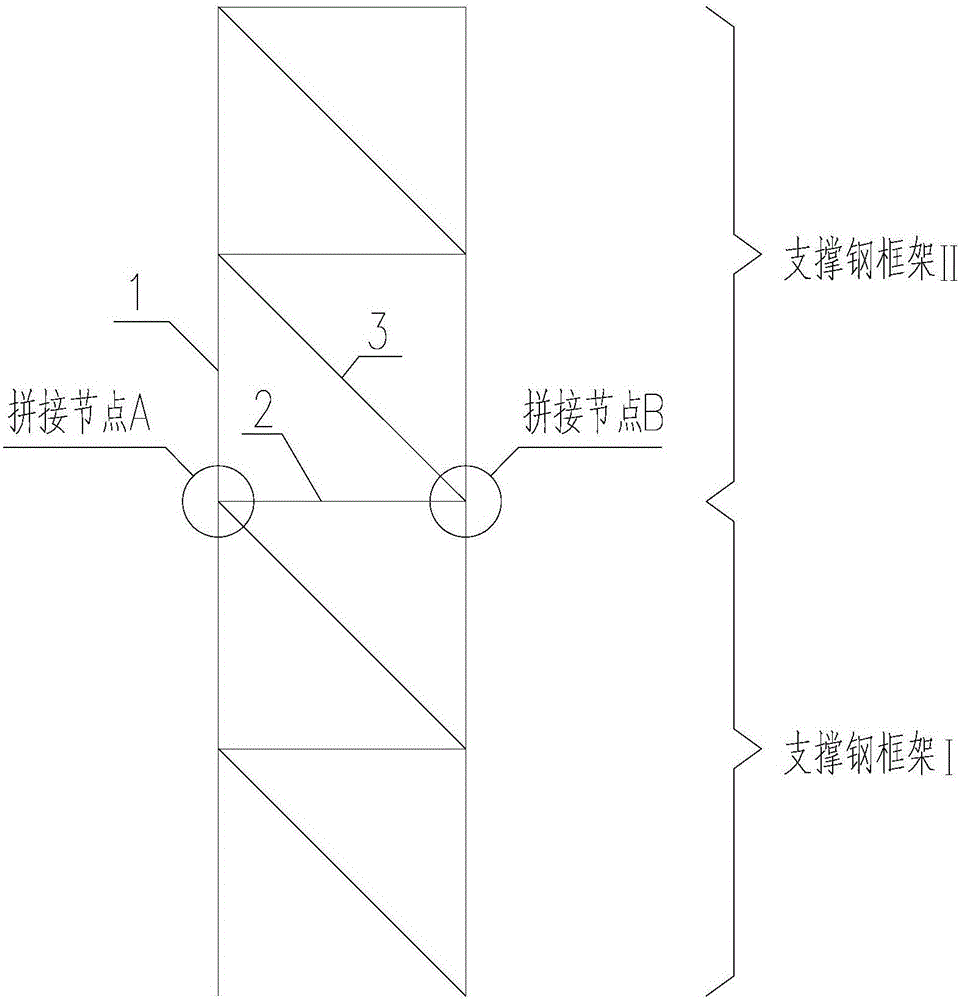

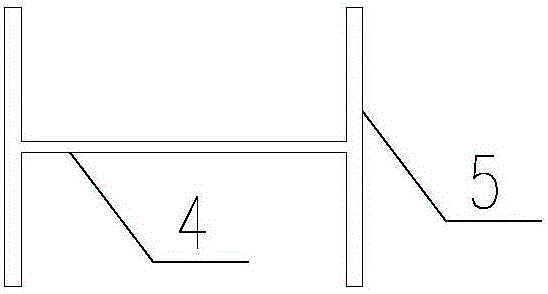

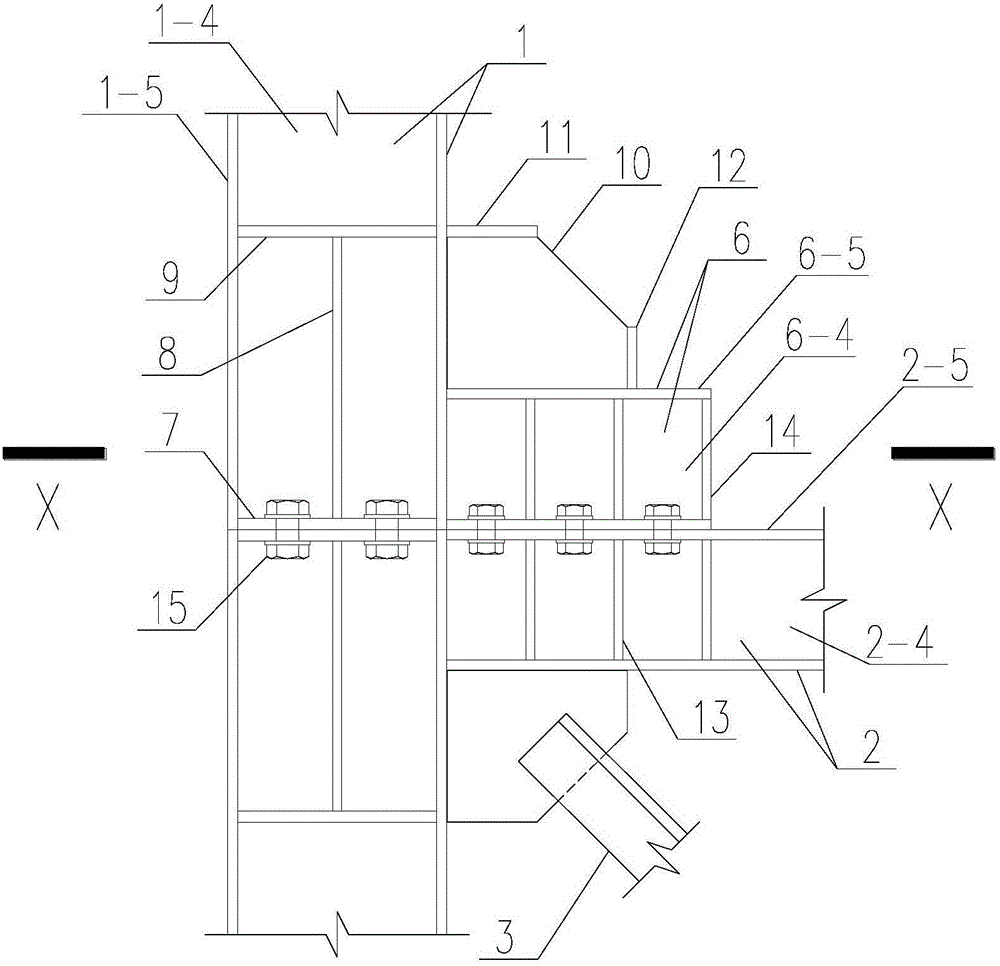

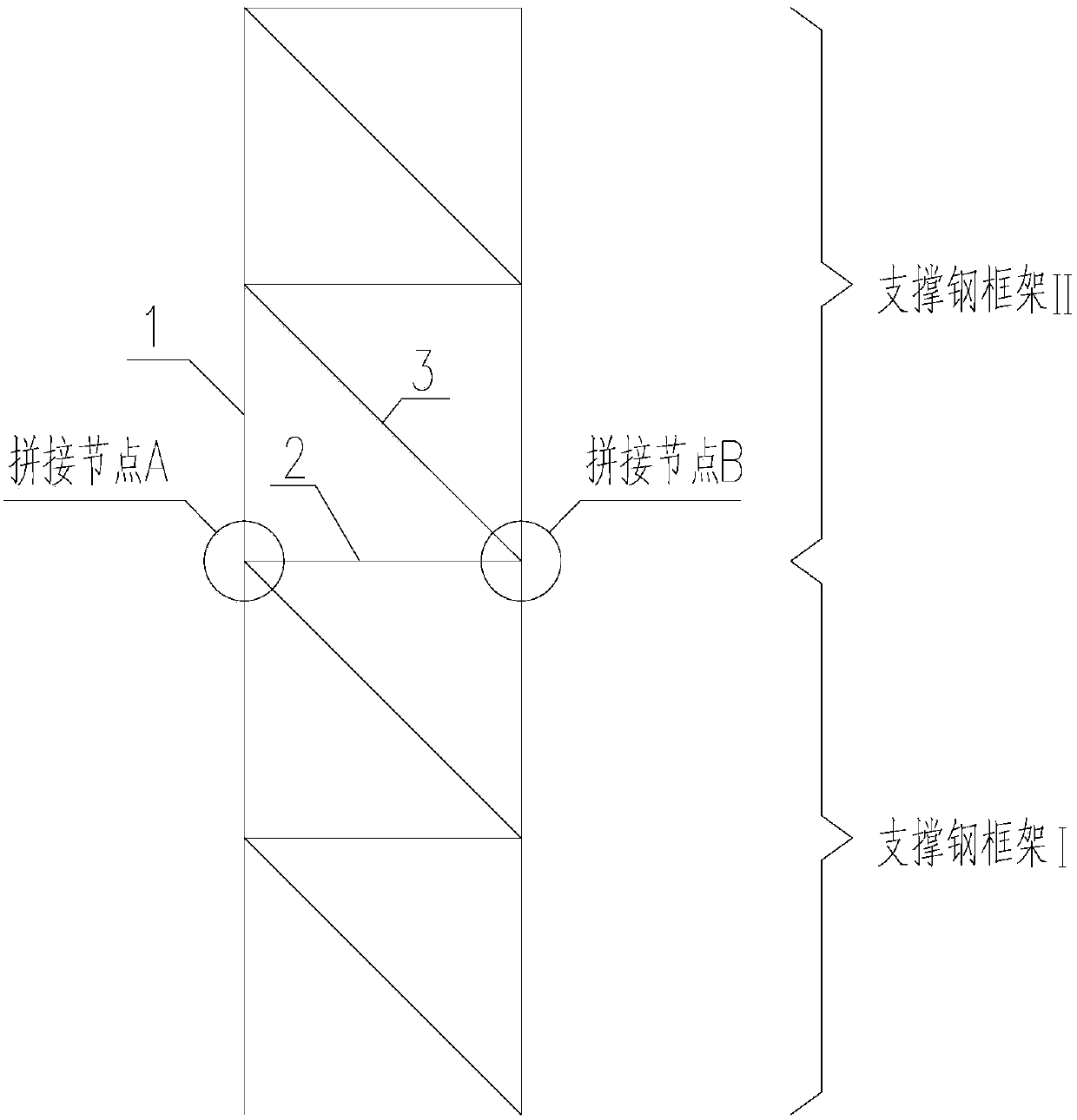

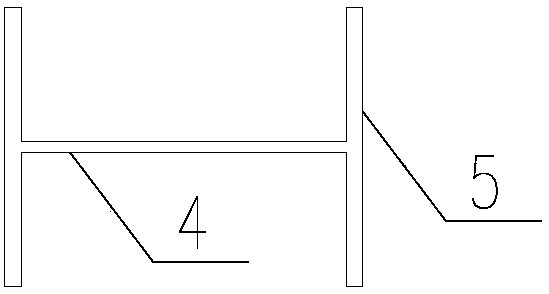

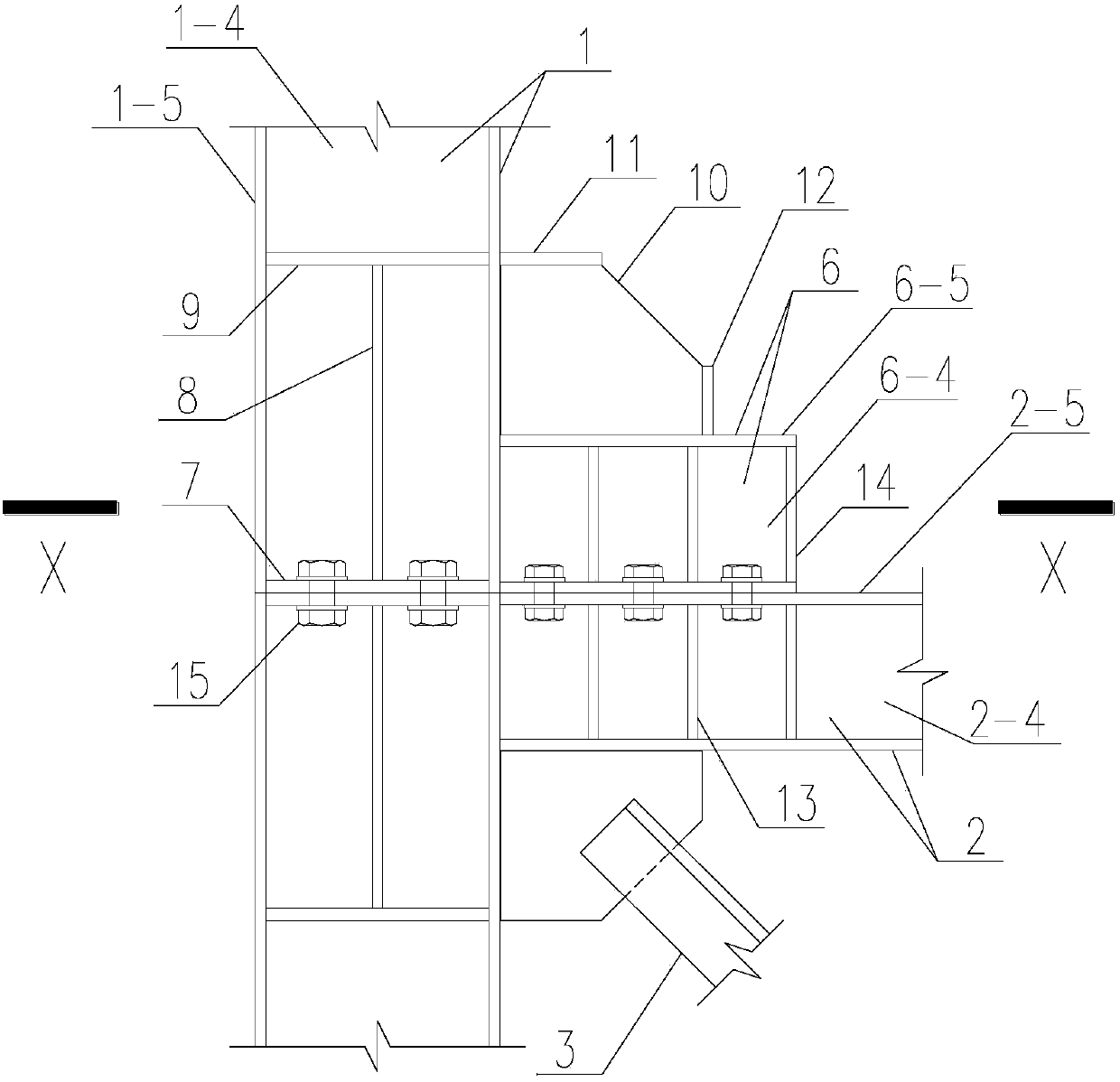

Prefabricated braced steel frame column end splicing joint structure

ActiveCN106013428AIncrease stiffnessImprove node bearing capacityBuilding constructionsSteel frameMaterials science

The invention provides a prefabricated braced steel frame column end splicing joint structure. The prefabricated braced steel frame column end splicing joint structure is located between two prefabricated braced steel frames. The braced steel frame I is located below the joint, and the braced steel frame II is located above the joint. Each braced steel frame is composed of H-shaped columns, H-shaped beams and supports. According to the braced steel frame I, end plates are welded to the tops of the H-shaped columns, stiffening ribs are arranged at the joints of the H-shaped columns and the H-shaped beams, horizontal stiffening ribs are welded to the H-shaped columns, vertical stiffening ribs are arranged between the end plates of the H-shaped columns and the horizontal stiffening ribs of the H-shaped columns, stiffening ribs are welded to the H-shaped beams, and bolt holes are formed in upper flanges of the H-shaped beams. According to the braced steel frame II, end plates are welded to the bottoms of the H-shaped columns, H-shaped joggle beams are welded to the bottoms of the H-shaped columns, stiffening ribs are welded to the H-shaped joggle beams, bolt holes are formed in lower flanges of the H-shaped joggle beams, stiffening ribs are arranged at the joints of the H-shaped columns and the H-shaped joggle beams, horizontal stiffening ribs are welded to the H-shaped columns, and vertical stiffening ribs are arranged between the end plates of the H-shaped columns and the horizontal stiffening ribs of the H-shaped columns.

Owner:TONGJI UNIV

precast concrete elements

The invention relates to a prefabricated concrete component, which belongs to the technical field of prefabricated reinforced concrete structures; the prefabricated concrete component of the present invention is equipped with two-way intersecting distributed steel bars inside, and the included angle between the distributed steel bars and the side of the prefabricated concrete component is an acute angle or an obtuse angle.

Owner:山东艾科福建筑科技有限公司

Novel anti-drawing composite beam joint structure and manufacturing process

PendingCN111236069AClosely connectedActive connectionCeramic shaping apparatusBridge structural detailsVertical shearRebar

The utility model discloses a novel anti-drawing composite beam joint structure. A stud shear key is arranged on the upper surface of an upper flange of the steel beam, the concrete slab is arranged on the steel beam, the steel beam is a support of the concrete slab, a plurality of embedded part plates are arranged on a connecting edge of the concrete slab, each embedded part is divided into an embedded part, an exposed part and an outwards-extending connecting anti-drawing head, and the embedded parts are located in the concrete slab. The embedded part of the embedded part plate is provided with a stressed steel bar hole, and the position of the stressed steel bar hole corresponds to the position of a stressed bar in the concrete plate; connecting steel bar holes are formed in the exposedparts of the embedded part plates, and the sizes of the connecting steel bar holes need to correspond to those of connecting steel bars; a U-shaped hole is formed between the concrete slab and the steel beam, and the U-shaped hole is filled with polymer mortar. The overall stress performance of the composite beam bridge, the tightness between the top flange of the steel beam and concrete, the vertical shear resistance and durability between new concrete and old concrete, the anti-drawing performance and shear resistance between steel and concrete and the bearing capacity of a joint at the manufacturing position are improved.

Owner:浙江交工国际工程有限公司

Tear-resistant rubber material

The invention discloses a tear-resistant rubber material which is prepared from the following raw materials in parts by weight: 30-50 parts of chloroprene rubber, 15-22 parts of styrene-butadiene rubber, 3-8 parts of an antioxidant, 6-11 parts of highly dispersible silica, 6-8 parts of modified fly ash, 6-11 parts of an antioxidant RD, 5-7 parts of N220 reinforcing carbon black, 7-14 parts of octylphenolic resin, 2-6 parts of a silane coupling agent, 0.2-2 parts of dicumyl peroxide, 6-8 parts of nano-alumina, 3-5 parts of 2-mercaptoimidazoline, 2-4 parts of a scorch retarder, 5-9 parts of antimonous oxide, 4-7 parts of activated zinc oxide, 4-8 parts of carbon black N100. The tear-resistant rubber material has the benefits of being good in toughness and capable of resisting torsion and shear force and preventing the rubber from tearing.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

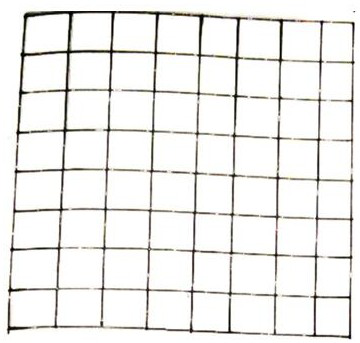

Enhanced additive process and mold strengthening method based on arc fuse

ActiveCN112453421BHigh hardnessHigh strengthAdditive manufacturing apparatusFurnace typesStructural engineeringUltimate tensile strength

The invention discloses an enhanced material-adding process based on arc fuses, in which an arc fuse material-added layer is formed for each fuse-added material, and the arc fuse-added material layer is hammered; each arc fuse material-added layer is 2~ 3 layers, the grid frame is laid; after the grid frame is laid, the grid frame is hammered to make the grid frame and the arc fuse additive layer fit together; when the grid frame is laid, the arc fuse additive layer is laid The grid is positioned by welding the nails; the hardness of the grid frame material and the nail material are greater than that of the fuse material, and the melting points of the grid frame material and the nail material are lower than the melting point of the fuse additive material, so that the grid frame The nails are gradually melted with the progress of the fuse additive, and finally combined with the arc fuse additive layer as a whole. In the mold strengthening method of the present invention, the mold is strengthened by arc fuse material addition and then tempering heat treatment is performed. The invention can enhance the strength and hardness of the added material area, eliminate the residual stress and improve the toughness of the mould.

Owner:康硕(山西)低应力制造系统技术研究院有限公司

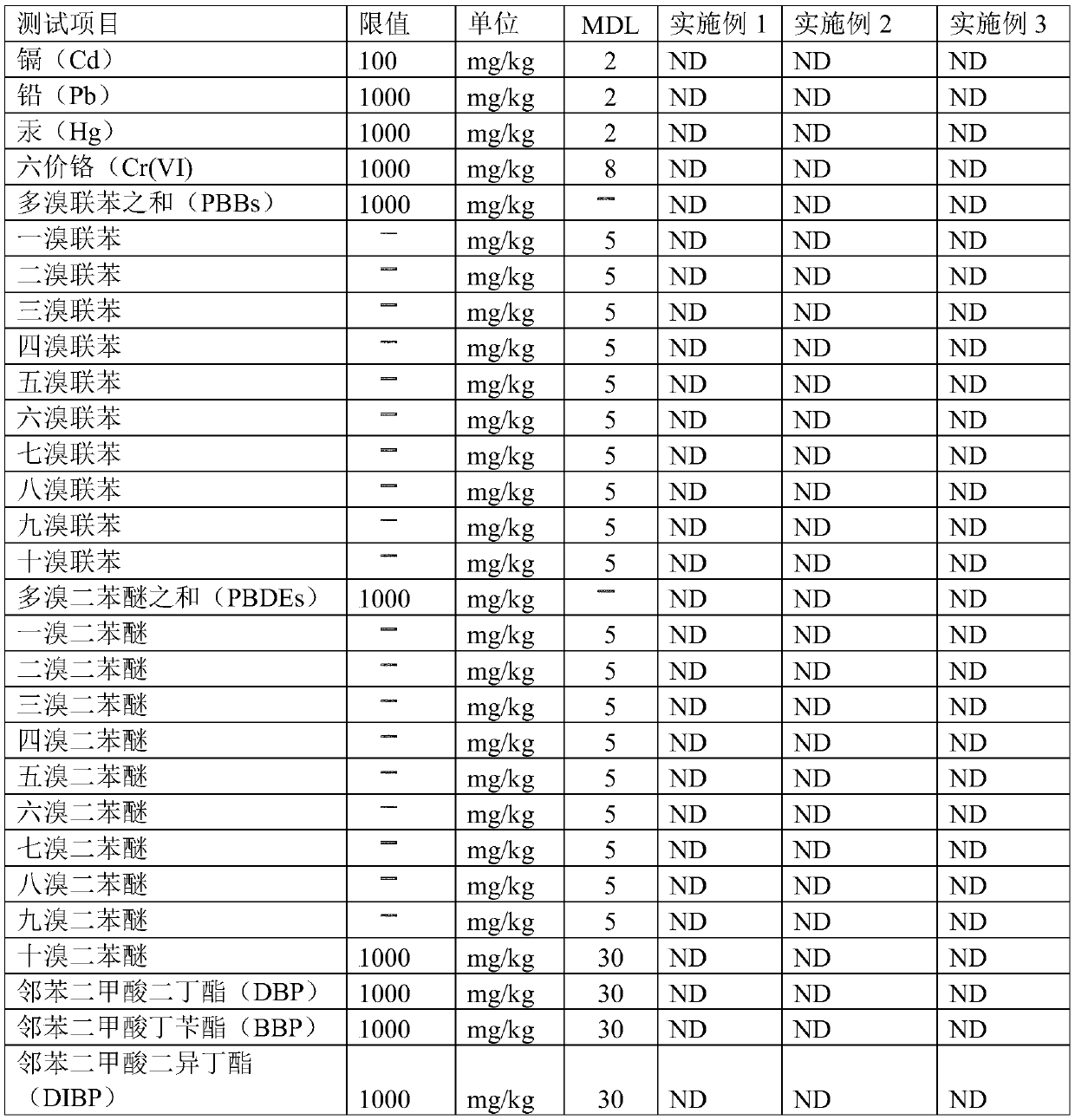

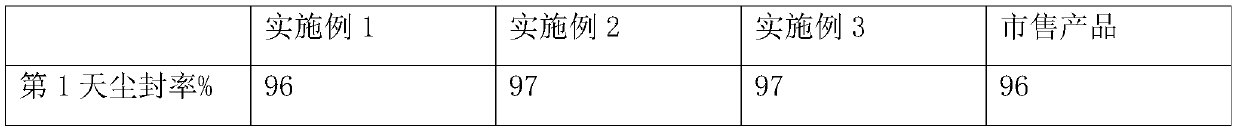

Long-acting dust sealing agent and preparation method thereof

InactiveCN110862718APrevent volatilizationAvoid contactOther chemical processesCellulose coatingsCellulosePolycaprolactone

The invention discloses a long-acting dust sealing agent and a preparation method thereof, and belongs to the technical field of dust sealing agents. The problems that an existing dust sealing agent is short in dust suppression period, prone to destroying soil and the like are solved. The dust sealing agent is composed of 30-50 parts of plant cellulose, 10-30 parts of polycaprolactone, 13-18 partsof sodium lignin sulfonate, alginate, polyfumaric acid, starch grafted acrylate, sodium carbonate, starch modified polyacrylamide, carboxymethyl starch and deionized water. The preparation method comprises the steps: adding sodium lignin sulfonate into deionized water to adjust the pH value of the solution to 8-9; adding plant cellulose and polycaprolactone into the solution, sequentially addingpolyfumaric acid, starch grafted acrylate, sodium carbonate and starch modified polyacrylamide, uniformly mixing, adjusting the pH value to be neutral, and then adding carboxymethyl starch; and filtering the obtained solution by a microfiltration membrane, and carrying out spray drying. The long-acting dust sealing agent can be used for roads, mining areas and other places with serious dust raising.

Owner:山东朗森高分子材料有限公司

A fiber composite material imitating the structure and function of lobster cuticle

ActiveCN112874032BShear resistanceImprove impact resistanceSynthetic resin layered productsVehicle componentsCrack resistanceCrazing

Owner:JILIN UNIV

Concrete member

PendingCN114411999ASolve the problem of low mechanical performanceImprove structural strengthWallsHeat proofingAcute angleArchitectural engineering

The invention provides a concrete member. The concrete member comprises a main body, a first fixing plate, a second fixing plate, a third fixing plate, a fourth fixing plate and a fifth fixing plate, the first fixing plate is connected with the lower surface of the main body; the main body comprises a shell and steel bars, and the included angle between the steel bars and the shell is an acute angle. The first fixing plate, the second fixing plate, the third fixing plate, the fourth fixing plate and the fifth fixing plate are connected with the main body, the structural strength of the concrete member is greatly improved, and the steel bars distributed in a two-way cross mode are fixedly connected with the fourth fixing plate and the fifth fixing plate correspondingly; the included angles between the two ends of the steel bars and the fourth fixing plate and between the two ends of the steel bars and the fifth fixing plate are acute angles, and shearing force borne by the concrete member can be effectively resisted. And the two ends of the steel bars are connected with the fourth fixing plate and the fifth fixing plate, so that slippage between concrete can be reduced, the connecting performance of the concrete member is enhanced, and the reliability of the concrete member is improved.

Owner:佛山建装建筑科技有限公司

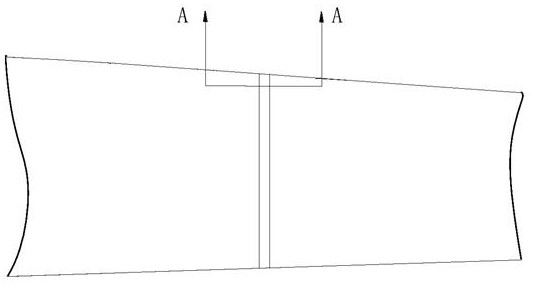

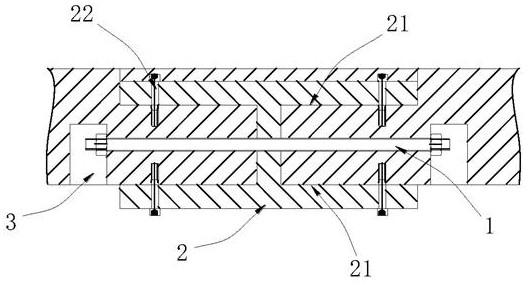

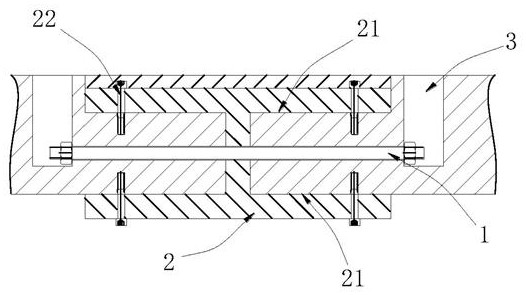

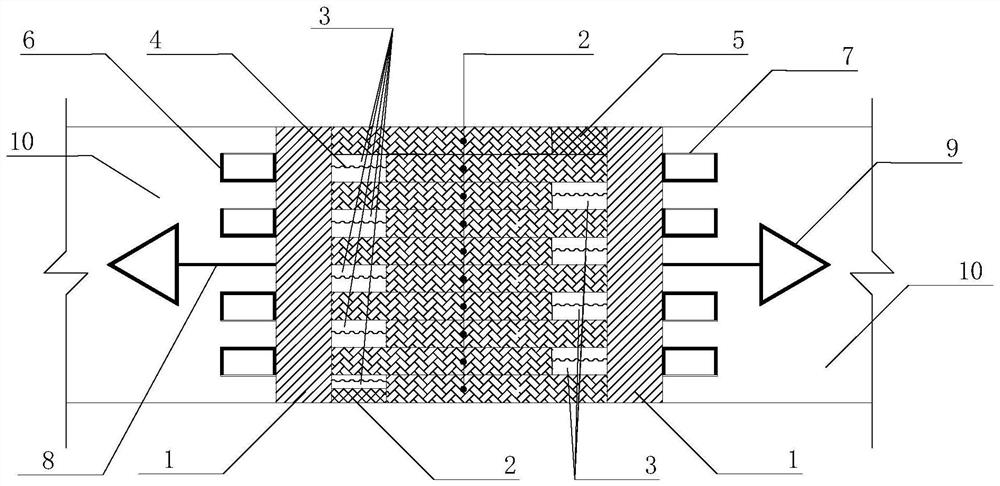

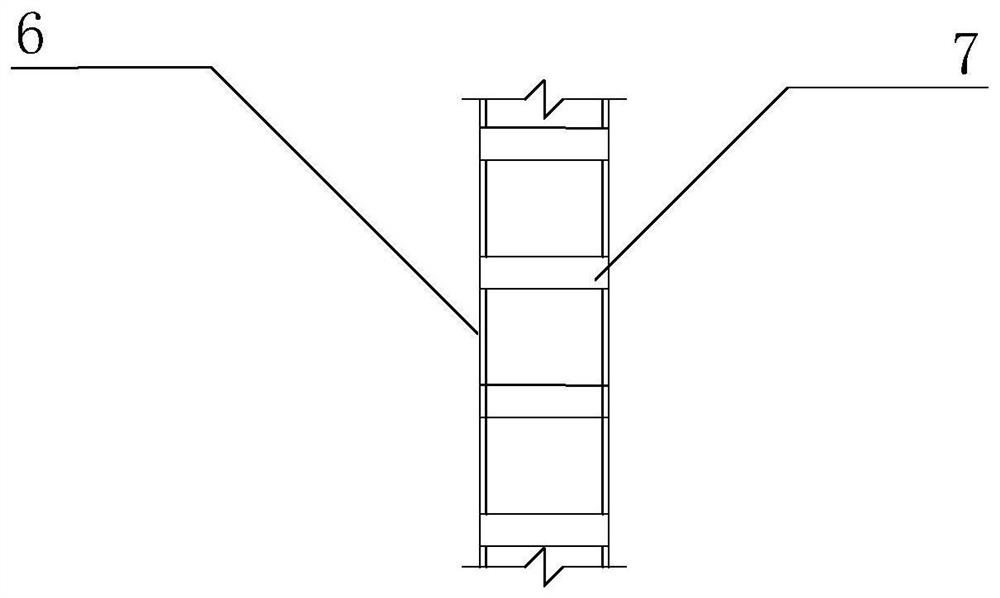

Anti-shearing connecting structure and segmented wind power blade

ActiveCN113339191AShear resistanceGuaranteed connection strengthMachines/enginesWind energy generationEngineeringMechanical engineering

The invention relates to the technical field of wind power blades, in particular to an anti-shearing connecting structure and a segmented wind power blade. The anti-shearing connecting structure comprises a first segment, a second segment and a connecting part, wherein the first segment and the second segment are arranged in the length direction of the wind power blade; a first connecting structure is arranged between the first segment and the second segment, and the first connecting structure is parallel to the length direction of the wind power blade and is used for fixing the first segment and the second segment; the connecting part comprises at least one matching surface, the connecting part is matched with the first segment and the second segment on the matching surface, and the matching surface is parallel to the length direction of the wind power blade; and a second connecting structure is arranged on the connecting part, the second connecting structure penetrates through the matching surface in the direction perpendicular to the length direction of the wind power blade, and the first segment and the second segment are fixed with the connecting part separately. According to the anti-shearing connecting structure, the length direction between the segments of the wind power blade and the direction perpendicular to the length direction are fixedly connected, so that the shearing force generated when the wind power blade rotates can be well resisted, and the connecting strength is guaranteed.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

A brick-concrete composite wall and its construction method

The invention relates to the technical field of building decoration engineering, and discloses a brick-concrete composite wall and its construction method, which are used for building side walls or building ceilings, including a cast-in-place concrete layer and one or two cast-in-place concrete layers. Each face brick layer on the surface is connected to the wall reinforcement cage in the cast-in-place concrete layer respectively; the back of the face brick is provided with tooth-shaped protrusions inserted into the cast-in-place concrete layer. In the present invention, by installing the facing bricks into the mold of the cast-in-situ concrete wall, the entire wall is equivalent to mortar, and the mortar fullness reaches 100%, so that the bonding of the facing bricks is very firm, and can be used for ceilings or building exterior walls. The occasions where the facing bricks are easy to fall off; the tooth-like protrusions are closely meshed with the concrete, making the facing bricks more difficult to fall off, and can also resist the shear force parallel to the facing bricks; Bricks will not fall if destroyed.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

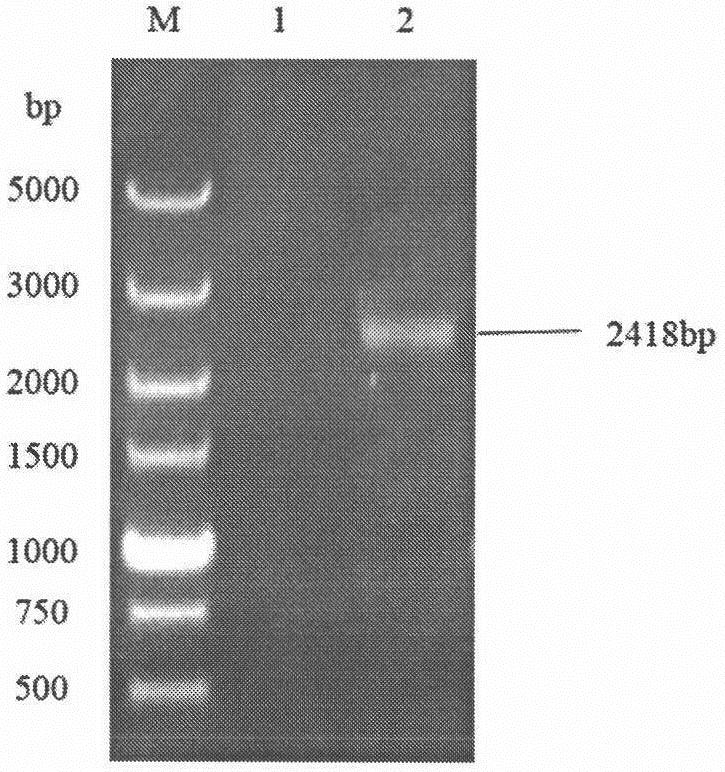

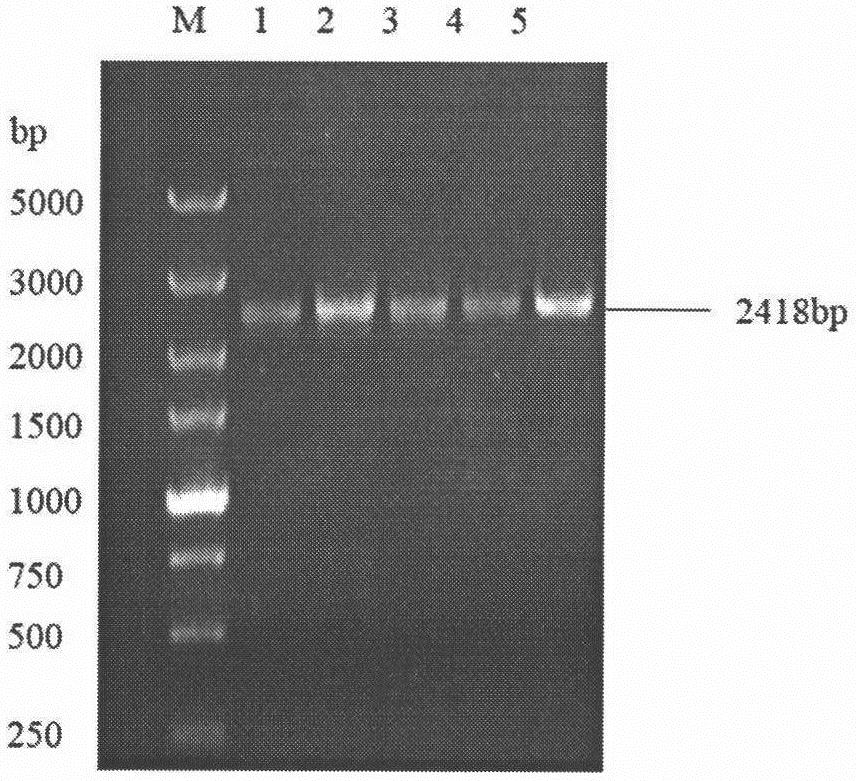

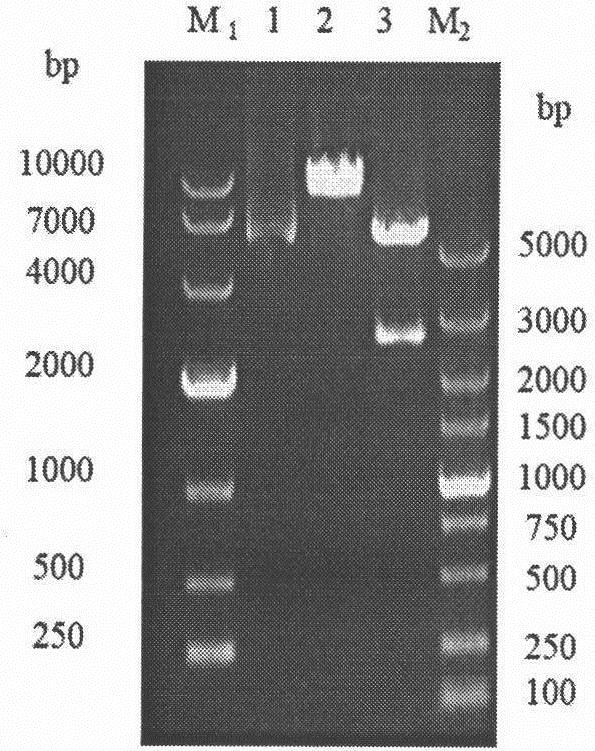

Construction, identification and expression method of porcine ACE2 eukaryotic expression recombinant plasmid vector

PendingCN112266933ACloning methods are extensive and stableBoosts gene transfection activityFermentationVector-based foreign material introductionMolecular biologyCell strain

The invention discloses a construction, identification and expression method of a porcine ACE2 eukaryotic expression recombinant plasmid vector. The method comprises the following steps: constructingan ACE2 eukaryotic expression vector, transfecting CHO cells, and screening stably-expressed pcDNA 3.1 (+)-ACE2 cell strains through G418 to obtain ACE2 protein with biological activity. The method has the advantages that (1) the reaction is quick, and only one hour is needed; (2) simplicity: the method is not influenced by fragment enzyme digestion sites, and enzyme digestion is not needed; (3) high efficiency: the positive rate reaches 95% or above; and (4) seamlessness: extra sequences are not introduced. ACE2 exerts various body protection functions such as vasodilation, inflammation inhibition and fibrosis resistance by targeted degradation of AngII. Besides, as a functional receptor of severe acute respiratory syndrome coronavirus (SARS-CoV), the porcine ACE2 eukaryotic expression recombinant plasmid vector has extraordinary clinical significance. The invention lays a foundation for deeply researching the biological function and the molecular mechanism of the porcine ACE2 servingas a potential virus receptor in porcine coronavirus infection and developing the ACE2 serving as a coronavirus targeted therapy drug.

Owner:NANJING AGRICULTURAL UNIVERSITY

A special mortar for anti-shear synchronous grouting and its preparation method

The invention discloses a special mortar for shear-resistant synchronous grouting. The material is composed of sand, slag powder, bentonite, active stimulating agent, ether polycarboxylic acid admixture and water, and the contents are respectively: 1070-1280kg / m 3 、300-360kg / m 3 、50-86kg / m 3 、80-120kg / m 3 、2.70-5.00kg / m 3 、300-320kg / m 3 . The special mortar for shear-resistant synchronous grouting of the present invention has good fluidity, filling, water retention and slump retention, and can improve the shear yield strength of existing shear-resistant synchronous grouting materials, thereby being more effective It can accurately control the uplift of the tunnel; it can also solve the problem of poor quality of fly ash or lack of resources, ensure the quality of slurry, and is low in cost and environmentally friendly. It is suitable for synchronous grouting construction of shield tunnels, especially large shield tunnels, in areas where fly ash resources are scarce or of poor quality.

Owner:SHANGHAI URBAN CONSTR MATERIAL CO LTD

Waterproof expansion joint structure and construction method of ultra-long underground structure

ActiveCN110847245BAvoid formingAvoid temperature stressArtificial islandsUnderwater structuresArchitectural engineeringExpansion joint

The invention discloses a waterproof expansion joint structure of an ultra-long underground structure and a construction method thereof, which comprises two end steel plates respectively connected with the main body concrete structures on both sides, and the steel plates at the two ends are intersected and spaced apart from each other on the respective opposite sides A toothed steel plate is provided, and the toothed steel plate leaves a space for expansion and contraction from the side of the opposite end steel plate, and the end of the toothed steel plate located in the other expansion and contraction spaces except the top expansion space is provided with a profiled steel plate. In the present invention, bayonet steel plates are respectively arranged at intervals on the steel plates at the ends of both sides. The bayonet steel plates on both sides are intersected with each other and there is space for expansion and contraction. They can offset each other to offset the deformation of the ultra-long underground structure, avoiding the generation of temperature stress, thereby avoiding the formation of temperature cracks, and at the same time, it is not necessary to drill precipitation wells and long-term precipitation like setting up post-casting belts, and the cost is low.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

A fiber composite material imitating the structure and function of coelacanth scales

ActiveCN112829413BStrong impact resistanceImpact resistanceSynthetic resin layered productsFibrous compositesCoelacanthus

A fiber composite material imitating the structure and function of coelacanth scales. The fiber composite material adopts a double-helix arrangement structure imitating coelacanth scales, and is formed by alternately laying up at least two groups of helical fiber resin layer structures; each group In the spiral fiber resin layer structure, the fiber resin layer takes the center line perpendicular to the center of the fiber resin layer as the axis, and rotates the same rotation angle from top to bottom to be arranged periodically; the fiber resin in each group of spiral fiber resin layer structure The layers are stacked alternately in sequence. The fiber composite material of the present invention imitates the double-helix fiber arrangement structure of the coelacanth scale, and obtains a fiber layer structure with stronger toughness than the traditional fiber composite material, which can well resist the shear force suffered by the fiber composite material and strengthen the structural toughness .

Owner:JILIN UNIV

Method for preparing middle frame, middle frame and electronic device

ActiveCN108688055BReduce manufacturing costIncrease profitCasings/cabinets/drawers detailsIdentification meansManufactured materialStructural engineering

The invention discloses a method for preparing a middle frame, the middle frame and electronic equipment. The method comprises the following steps: stamping a plane metal panel to form a groove in theedge of the plane metal panel; stretching the plane metal panel with the groove to form a metal outer frame, wherein the metal outer frame is provided with a bottom surface and an annular side framewhich is perpendicular to and surrounds the bottom surface, and the groove is formed in the side wall of the side, facing the bottom surface, of the annular side frame; and carrying out nano injectionmolding treatment on the metal outer frame and defining an accommodating space in the metal outer frame based on the groove to form a plastic structure so as to form the middle frame. Therefore, according to the method, the utilization ratio of raw materials is improved, the production cost is lowered, the processing time is shortened, and the production efficiency is improved.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

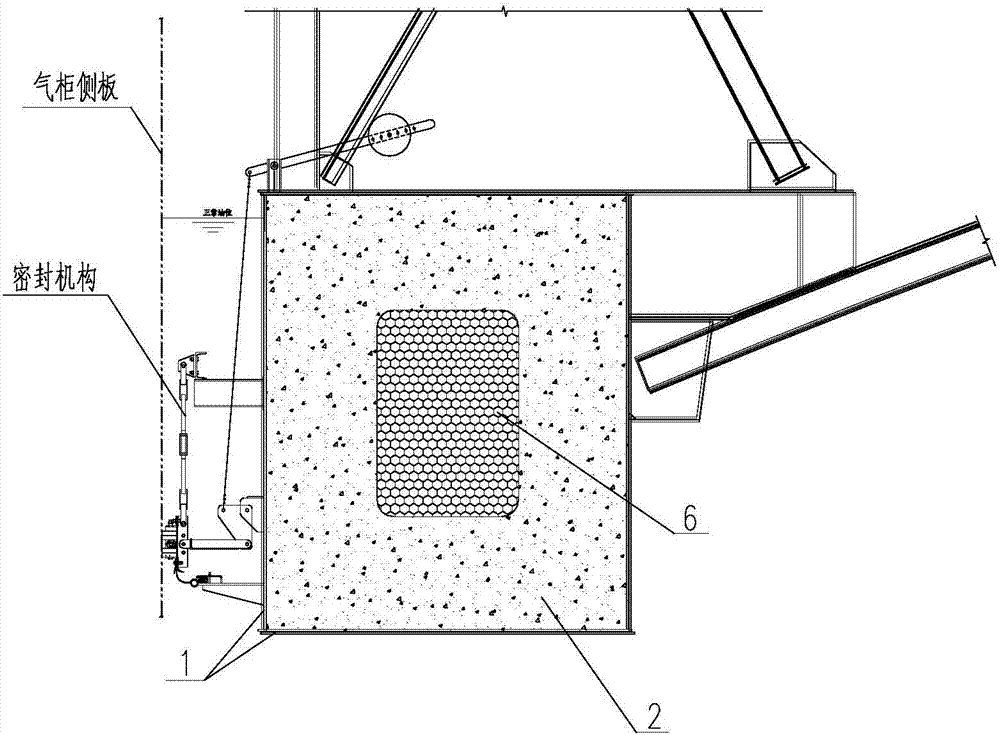

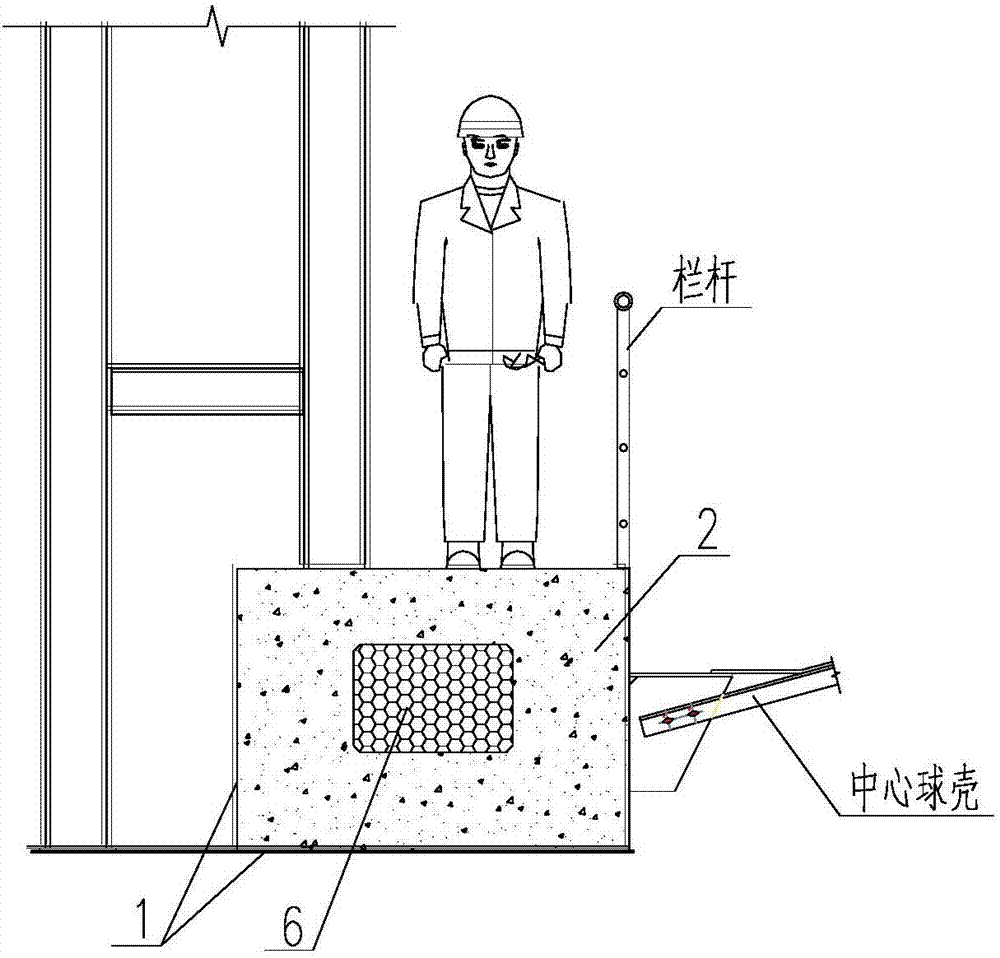

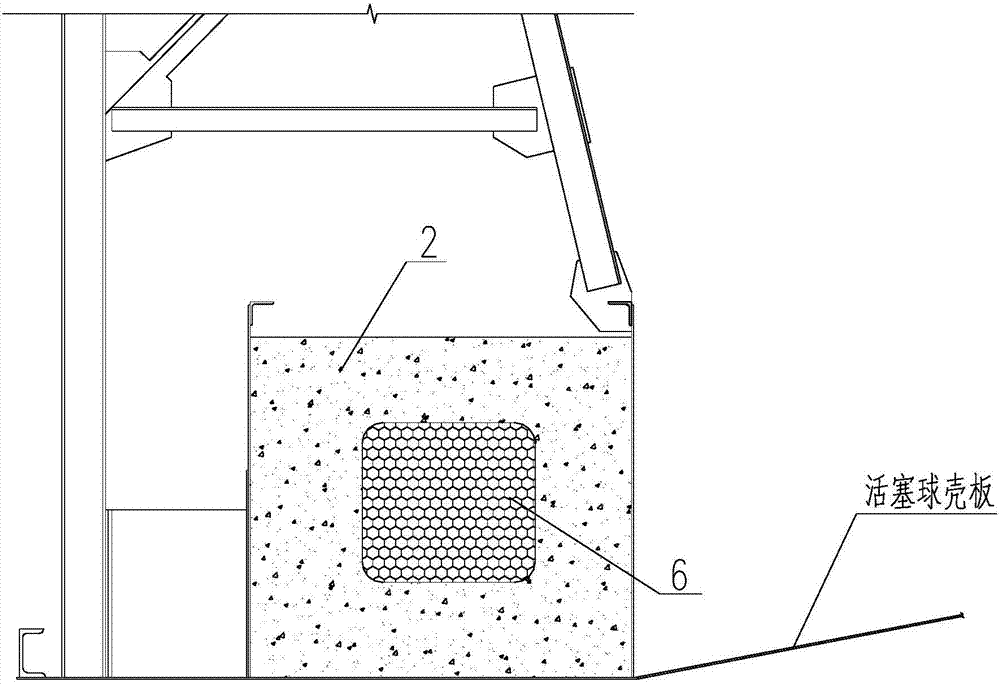

Dry gas holder piston steel concrete composite box girder

PendingCN106969253AAccurately and conveniently definedEasy to operateVariable capacity gas holdersEconomic benefitsEngineering

The invention discloses a dry gas holder piston steel concrete composite box girder. The dry gas holder piston steel concrete composite box girder comprises an open box girder shell, box girder concrete, a box girder stirrup, a box girder longitudinal reinforcement, a fluke, a lightweight material, a lightweight material bearing rod, a lightweight material block, and a piston box girder stiffening rib. The fluke is welded in the inside of the open box girder housing, the box girder stirrup and the box girder longitudinal reinforcement are located on the outside of the box girder, the lightweight material is arranged in the middle of the piston box girder, the bearing rod is arranged on the outside of the lightweight material, A certain amount of lightweight material blocks are arranged between the bearing rod and the lightweight material; the piston box girder stiffening rib is located on the inside of the piston box girder, and welded on the inside of the open box girder shell; and the box girder concrete is filled in the inner part of the open box girder shell. The dry gas holder piston steel concrete composite box girder solves the problems that the mechanical behavior of the structure and the piston box girder stiffening rib protruding and unable to form walkway caused by low pressure and the piston box girder concrete pouring insufficient are decreased, the investment is low, the construction time is short and the economic benefit is considerable.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

Prefabricated supporting steel frame column end splicing node structure

ActiveCN106013428BIncrease stiffnessImprove node bearing capacityBuilding constructionsShaped beamSteel frame

The present invention provides an assembled support steel frame column end splicing node structure, the assembled support steel frame column end splicing node structure is located between two assembled support steel frames, the support steel frame I is located at the lower part of the node, and the support steel frame II is located at upper part of the node. The supporting steel frame consists of H-columns, H-beams and braces. The supporting steel frame I welds the end plate on the top of the H-shaped column, sets the stiffener at the joint between the H-shaped column and the H-shaped beam, welds the horizontal stiffener on the H-shaped column, and sets the horizontal stiffener between the H-shaped column end plate and the H-shaped column Vertical stiffeners, welded stiffeners on the H-shaped beam, and bolt holes on the upper flange of the H-shaped beam. The supporting steel frame II welds the end plate at the bottom of the H-shaped column, welds the H-shaped spliced beam at the bottom of the H-shaped column, welds the stiffener on the H-shaped spliced beam, opens bolt holes on the lower flange of the H-shaped spliced beam, and splices the H-shaped column and the H-shaped Stiffeners are set at the beam joints, horizontal stiffeners are welded on the H-shaped columns, and vertical stiffeners are set between the end plates of the H-shaped columns and the horizontal stiffeners of the H-shaped columns.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com