Prefabricated braced steel frame column end splicing joint structure

A technology of joint structure and steel frame, applied in the direction of building structure, construction, etc., can solve the problems of affecting the connection between supporting steel frame and surrounding beams, not adapting to the development needs of industrialized buildings, and the form of splicing joints cannot meet the requirements, etc., to meet the requirements of prefabrication Assembly and installation requirements, meeting the bearing performance requirements of multi-storey buildings, and the effect of easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

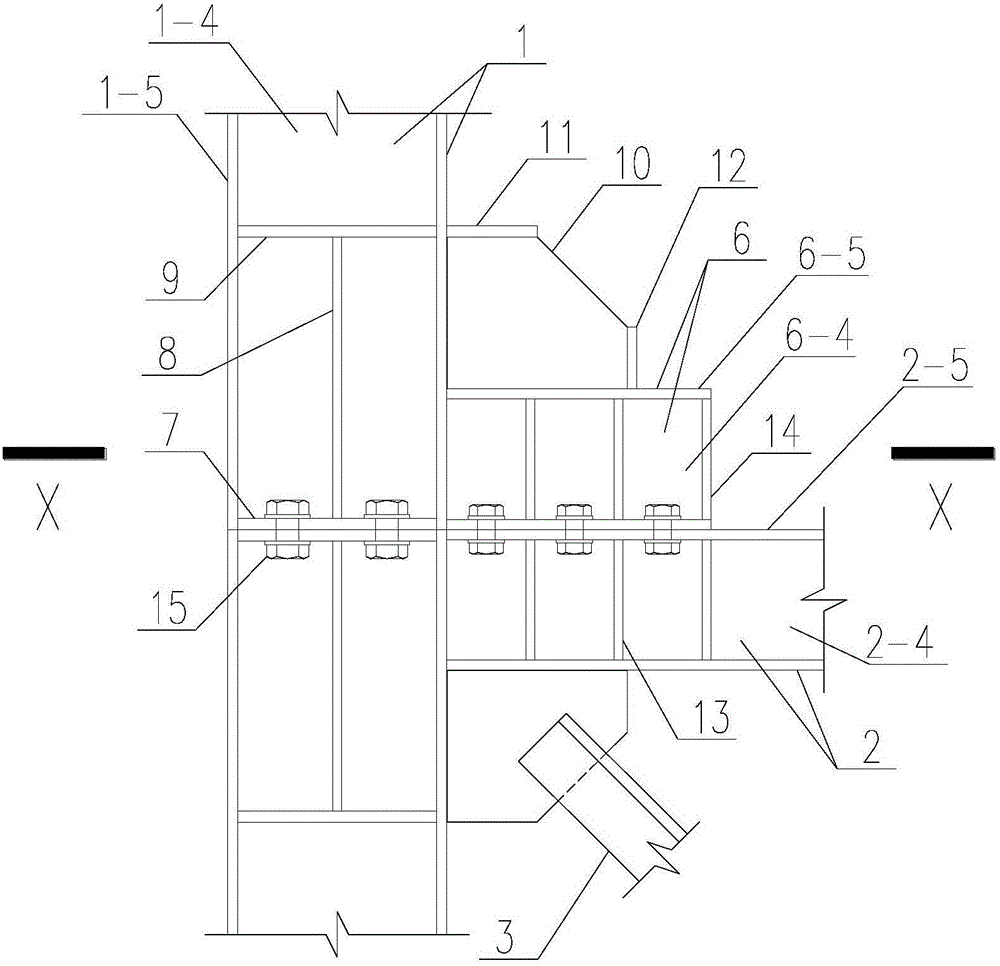

[0036] A prefabricated supporting steel frame column end splicing node structure, its structure is characterized by:

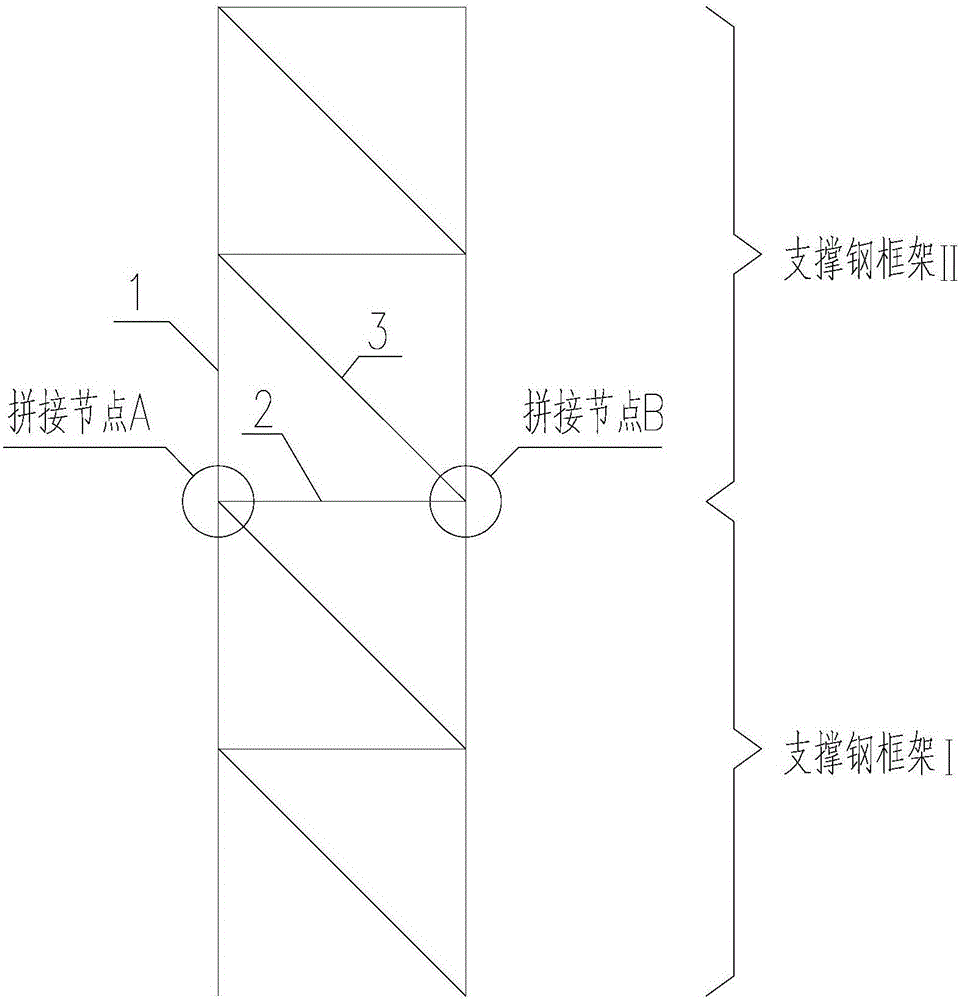

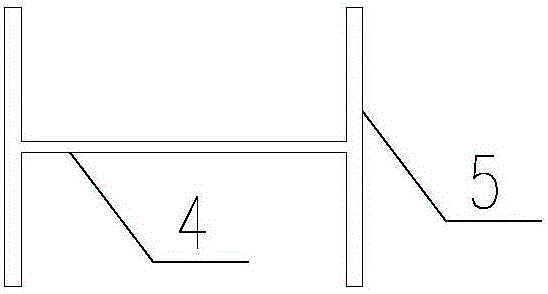

[0037] The column end splicing joint structure of the prefabricated supporting steel frame (referred to as the node) is located between two prefabricated supporting steel frames (referred to as the supporting steel frame), such as figure 1 As shown, the supporting steel frame I is located at the lower part of the node, and the supporting steel frame II is located at the upper part of the node. Such as figure 1 As shown, the supporting steel frame is composed of H-shaped columns 1, H-shaped beams 2 and supports 3,

[0038] As we all know, any H-shaped column and H-shaped beam in the art are compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com