Anti-shearing connecting structure and segmented wind power blade

A technology for connecting structures and wind power blades, which is applied to wind power generation, wind power generators that are consistent with the wind direction, and wind power generators. The effect of ensuring the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

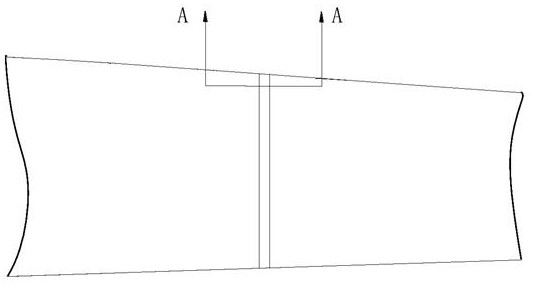

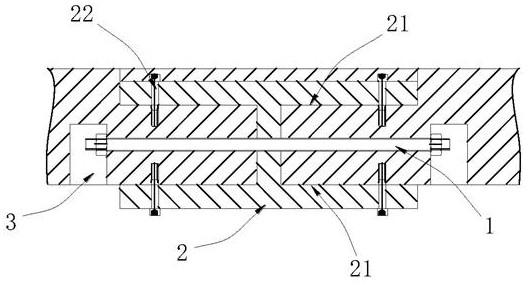

[0039] Such as Figures 1 to 2 Shown: A shear-resistant link structure comprising:

[0040] The first segment and the second segment are arranged along the length direction of the wind power blade, and the first connecting structure 1 is arranged between the first segment and the second segment. The first connecting structure 1 is parallel to the length direction of the wind power blade, and the first Segmentation and the second segment are fixed;

[0041]The connector 2, the connector 2 includes at least one mating surface 21, the connector 2 cooperates with the first segment and the second segment at the mating surface 21, the mating surface 21 is parallel to the length direction of the wind turbine blade, and the connector 2 is provided with There is a second connection structure 22 , which passes through the mating surface 21 along a direction perpendicular to the length of the wind turbine blade, and fixes the first segment and the second segment to the connector 2 respe...

Embodiment 2

[0049] Such as image 3 As shown: Different from Example 1, the process hole 3 is set on the outer surface of the wind power blade and extends inward. Since the process hole 3 is set on the outer surface of the wind power blade, it is more convenient for subsequent maintenance without entering into the wind power blade The first connecting structure 1 can be inspected and repaired inside.

Embodiment 3

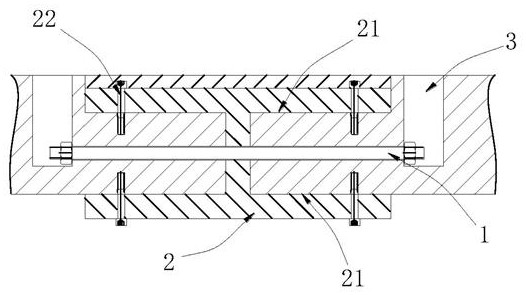

[0051] Such as Figure 4 As shown: different from Embodiment 1, the section of the connector 2 in the length direction of the wind turbine blade is T-shaped, and the connector 2 includes a horizontal section parallel to the length direction of the wind turbine blade and a vertical section perpendicular to the length direction of the wind turbine blade. The first subsection and the second subsection are respectively arranged at both ends of the vertical section, the first connection structure 1 passes through the vertical section, the second connection structure 22 is a screw, and the screw passes through the horizontal section, connecting the connector 2 with the first Segment and second segment are fixed.

[0052] Since the cross-section of the connecting piece 2 in the length direction of the wind turbine blade is T-shaped, although its shear resistance is slightly weaker, compared with the embodiment 1, the first segment and the second segment are more convenient for butt i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com