Dry gas holder piston steel concrete composite box girder

A dry gas tank and concrete technology, applied in the field of piston ring beam, can solve the problems of instability of piston fence, low operating pressure and high height of stiffener of piston box beam, and achieve the effect of fast, accurate and convenient position limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

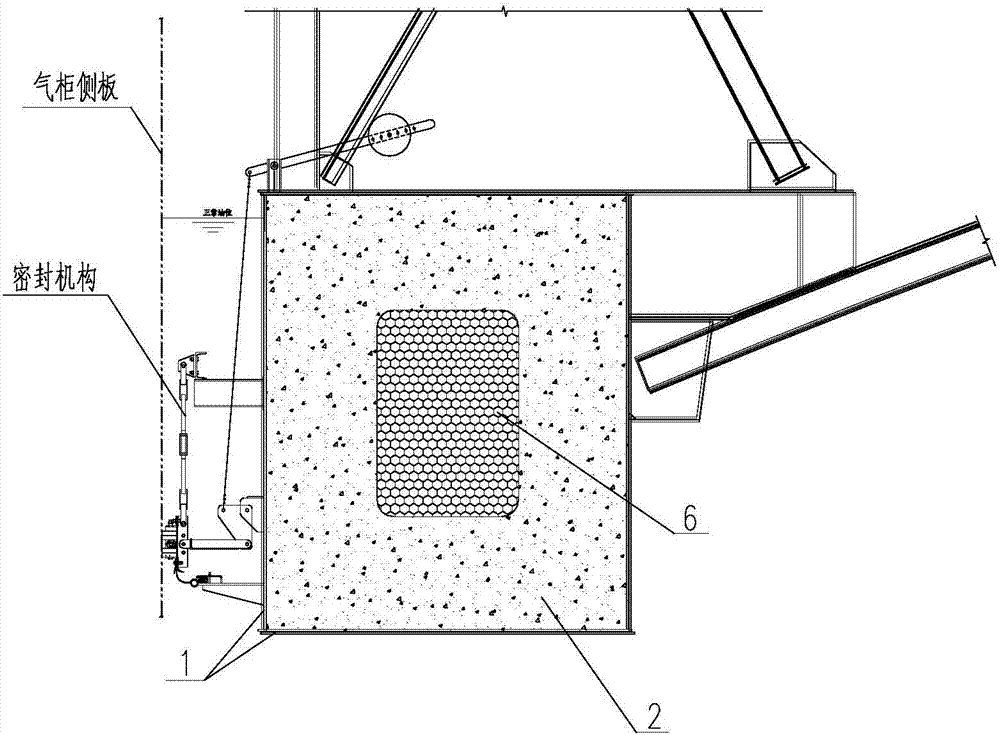

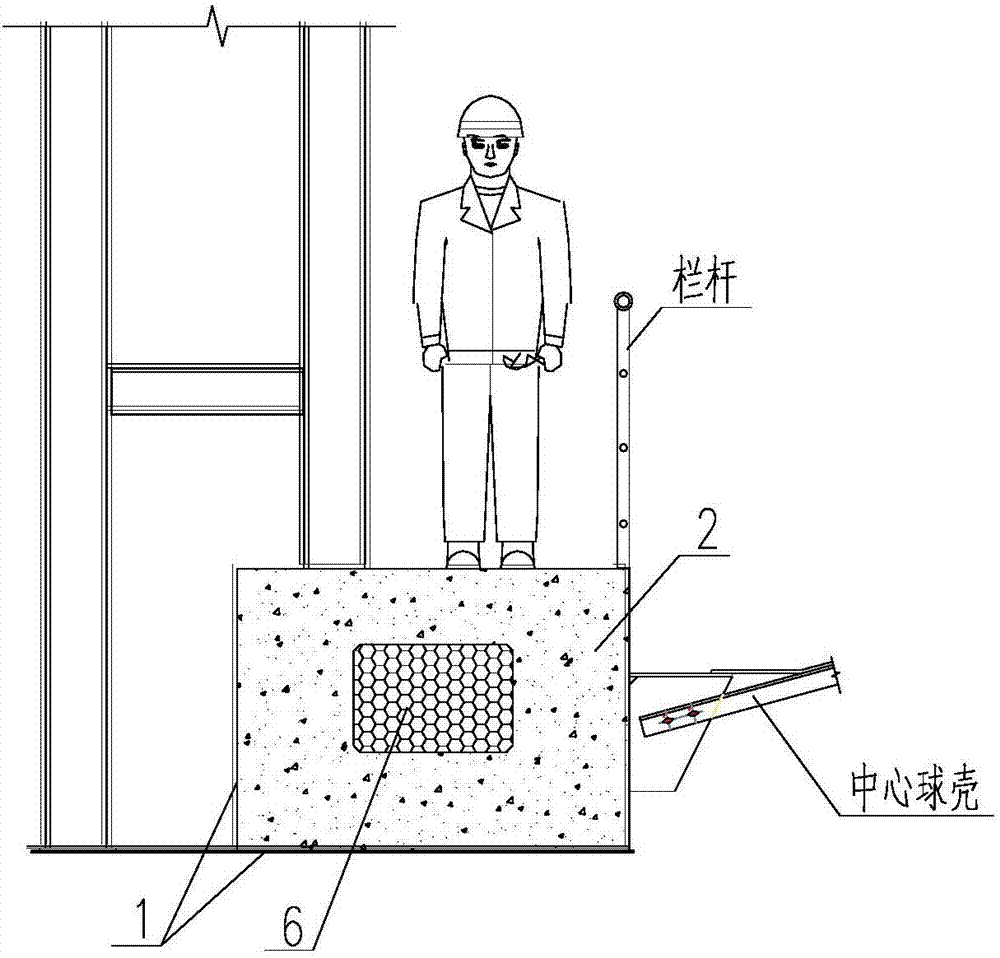

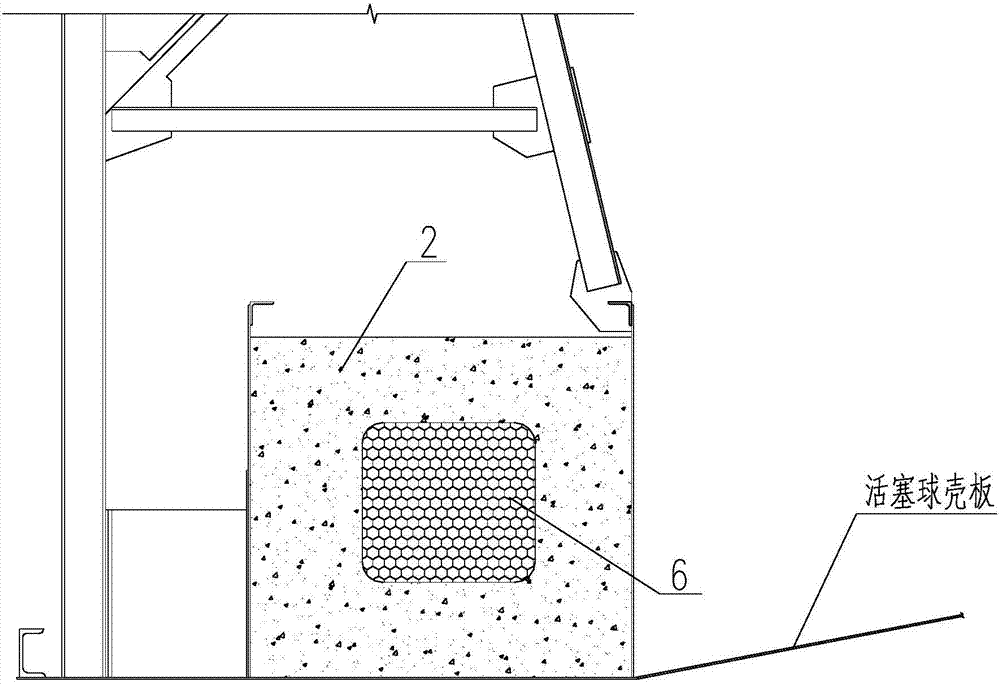

[0028] Such as Figure 1-6 As shown, a dry-type gas tank piston steel-concrete composite box girder of the present invention includes a box girder shell 1 with an open upper end and a box girder concrete 2; the inside of the box girder shell 1 is along the length direction of the box girder shell A light material 6 is extended, and the box girder concrete 2 is filled between the box girder shell 1 and the light material 6. It is characterized in that the light material 6 is limited by a positioning mechanism at a preset set location.

[0029] In the implementation process, the lightweight material should be set at the preset position in the box girder shell, and then concrete should be filled between the box girder shell and the lightweight material, and a positioning mechanism should be set to set the lightweight material at the expected position On the one hand, it is more accurate and convenient to define the position, and it can directly fill the uncured box girder concre...

Embodiment 2

[0030] Embodiment 2, on the basis of the above-mentioned embodiments, the positioning mechanism includes several lightweight material erecting ribs 7 arranged inside the box girder concrete 2 along the direction in which the lightweight material 6 extends; the lightweight material erecting One end of the rib 7 fixes the lightweight material 6 , and the other end extends to the bottom plate of the box girder shell 1 .

[0031] The light material is limited by erecting ribs. The lower end of the erecting rib abuts against the floor of the box girder shell, and the upper part surrounds the circumference of the longitudinal section of the light material, so that the position of the light material can be stably set, and the It can be included to a certain extent for lightweight materials and provide a certain strength.

Embodiment 3

[0032] Embodiment 3, on the basis of the above embodiments, the cross-section of the lightweight material 6 is a rectangle with four sides and the four sides of the ring beam cross-section;

[0033] The inside of the box girder concrete 2 is provided with light material erecting ribs 7 with a rectangular cross-section along the circumference of the light material 6, and the lightweight material erecting ribs 7 include a number of light material transverse bars parallel to the longitudinal section of the box girder. Erecting ribs 71, several vertical erecting ribs 72 of lightweight materials perpendicular to the longitudinal section of the box girder.

[0034] The setting of the vertical ribs of the light material not only supports the light material during the installation process, but also increases the strength to resist the shearing force.

[0035] Preferably, the number and position of the longitudinal ribs 72 are determined by the size of the cavity, and the size and spac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com