A fiber composite material imitating the structure and function of coelacanth scales

A technology of fiber composite materials and coelacanth, which is applied in the field of fiber composite materials imitating the structure and function of coelacanth scales, can solve problems such as poor strength, difficulty in finding effective ways to improve interlayer toughness, and single laying structure. Achieve the effects of changing the transmission path, diversifying the fiber arrangement, and improving the impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

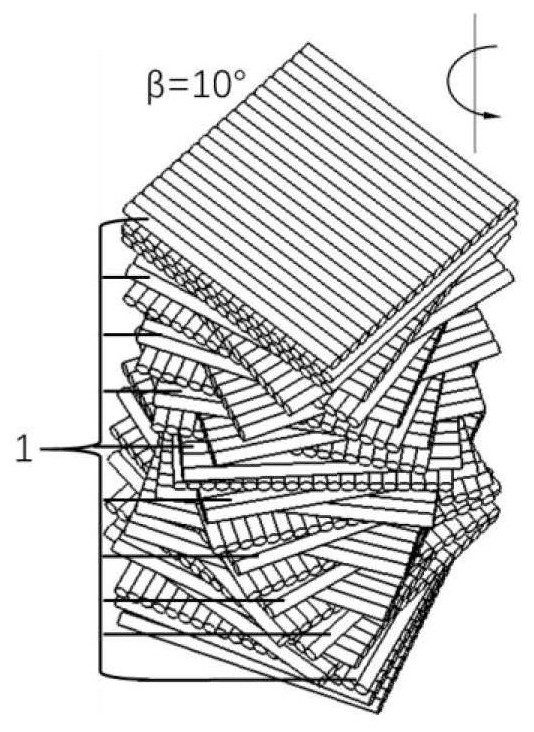

[0067] like Figure 2a , 2b As shown in and 2c, this embodiment one discloses a fiber composite material imitating the structure and function of coelacanth scales, such as figure 1 As shown, the layered structure of the fiber composite material imitating the structure and function of coelacanth scales adopts a double-helix layered structure based on coelacanth scales.

[0068] The fibrous composite material imitating the structure and function of coelacanth scales is formed by laminating two sets of helical fiber resin layer structures alternately and then pressing them together, wherein:

[0069] Both the first fiber resin layer 1 in the first group of spiral fiber resin layer structure and the second fiber resin layer 2 in the second group of spiral fiber resin layer structure are made of unidirectional fiber prepreg impregnated with resin;

[0070] In the structure of the first group of spiral fiber resin layers, taking the center line perpendicular to the center of the f...

Embodiment 2

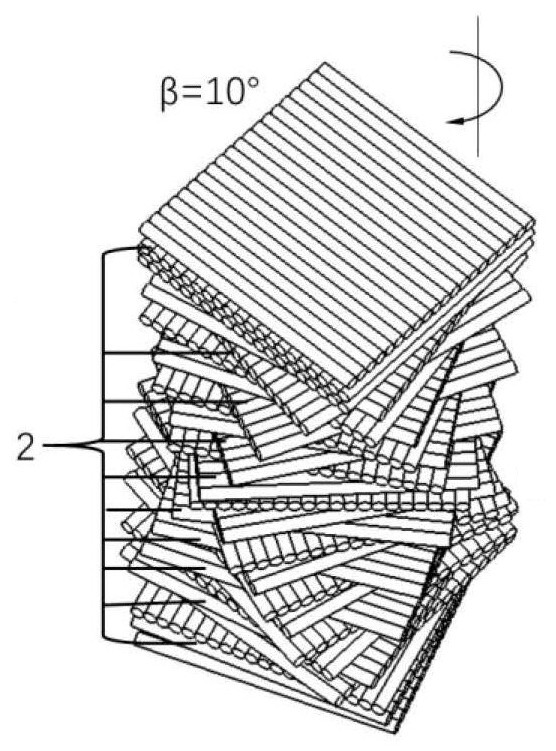

[0076] like Figure 3a , 3b As shown in and 3c, the second embodiment discloses a fiber composite material imitating the structure and function of coelacanth scales, such as figure 1 As shown, the layered structure of the fiber composite material imitating the structure and function of coelacanth scales adopts a double-helix layered structure based on coelacanth scales.

[0077] The fibrous composite material imitating the structure and function of coelacanth scales is formed by laminating two sets of helical fiber resin layer structures alternately and then pressing them together, wherein:

[0078] Both the first fiber resin layer 1 in the first group of spiral fiber resin layer structure and the second fiber resin layer 2 in the second group of spiral fiber resin layer structure are made of unidirectional fiber prepreg impregnated with resin;

[0079] In the structure of the first group of spiral fiber resin layers, taking the center line perpendicular to the center of the...

Embodiment 3

[0085] like Figure 4a , 4b As shown in and 4c, the present embodiment three discloses a fiber composite material imitating the structure and function of coelacanth scales, such as figure 1 As shown, the layered structure of the fiber composite material imitating the structure and function of coelacanth scales adopts a double-helix layered structure based on coelacanth scales.

[0086] The fibrous composite material imitating the structure and function of coelacanth scales is formed by laminating two sets of helical fiber resin layer structures alternately and then pressing them together, wherein:

[0087] Both the first fiber resin layer 1 in the first group of spiral fiber resin layer structure and the second fiber resin layer 2 in the second group of spiral fiber resin layer structure are made of unidirectional fiber prepreg impregnated with resin;

[0088] In the structure of the first group of spiral fiber resin layers, taking the center line perpendicular to the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com