Waterproof expansion joint structure and construction method of ultra-long underground structure

A technology for underground structures and expansion joints, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of threatening the safety of the main structure and the loss of material economy, so as to prevent being pulled out of the concrete and prevent the surface External deformation, the effect of increasing the stiffness of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

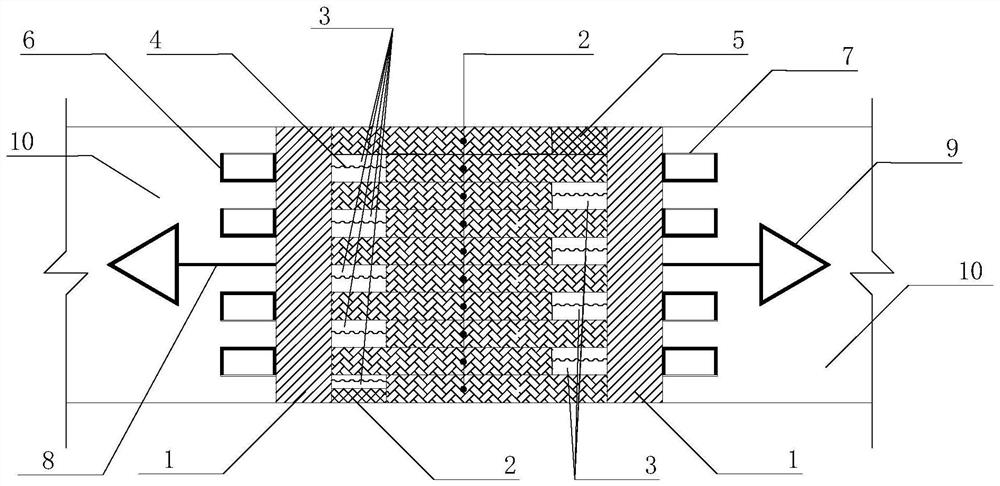

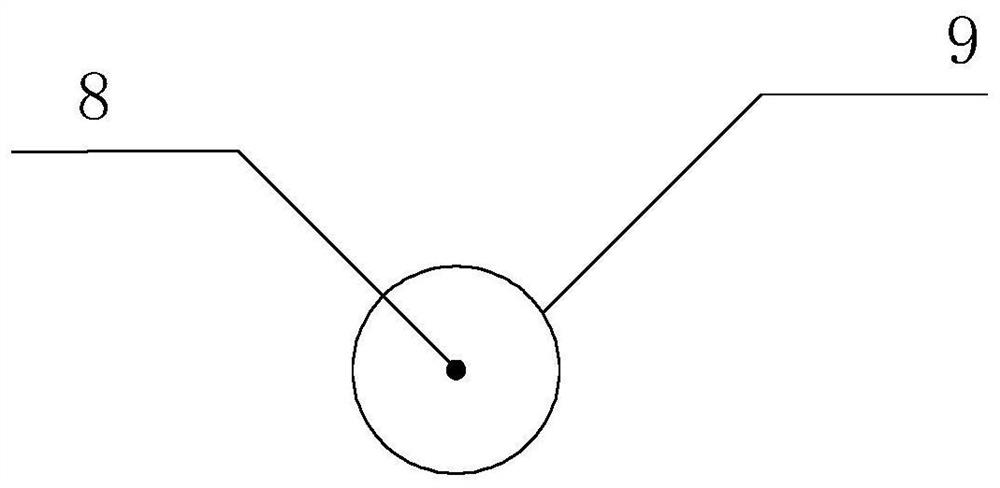

[0039] like figure 1 As shown, the present invention is a waterproof expansion joint structure of an ultra-long underground structure, including end steel plate 1, bayonet steel plate 2, profiled steel plate 4, rubber block 5, channel steel 6, trim strip 7, anchoring steel bar 8 and cone shaped anchor 9.

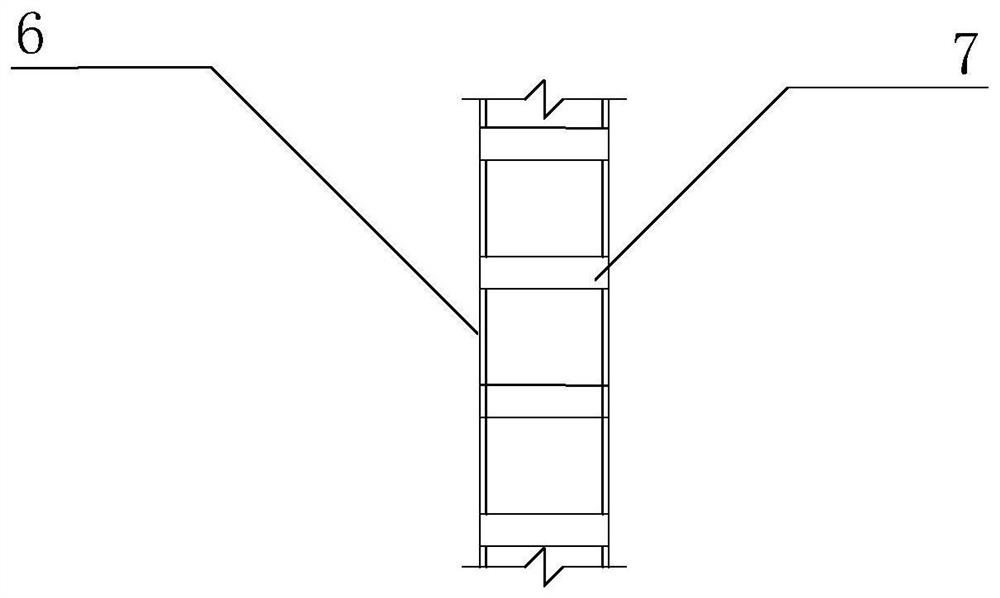

[0040] like figure 2 As shown, several channel steels 6 are arranged at intervals on the side of the end steel plate facing the main concrete structure, and the channel steels are arranged opposite to each other with the horizontal center line of the end steel plate as the axis, and the tip positions of the channel steel 6 are arranged at intervals. Several fringe strips 7 are arranged every 200mm to 500mm. In the present invention, the tip of the channel steel is easy to open when it receives an out-of-plane bending moment, and the fring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com