Heatproof microencapsulated essence and its preparation method

A technology of microencapsulation and flavoring, which is applied in the direction of microcapsule preparation, microsphere preparation, essential oil/fragrance, etc. It can solve the problem that the wall material strength, heat resistance and particle size distribution of microcapsule flavoring cannot meet the requirements, and the product is difficult to filter Separation, high moisture content and other problems, to achieve the effect of small droplets, good fluidity, and small essence droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

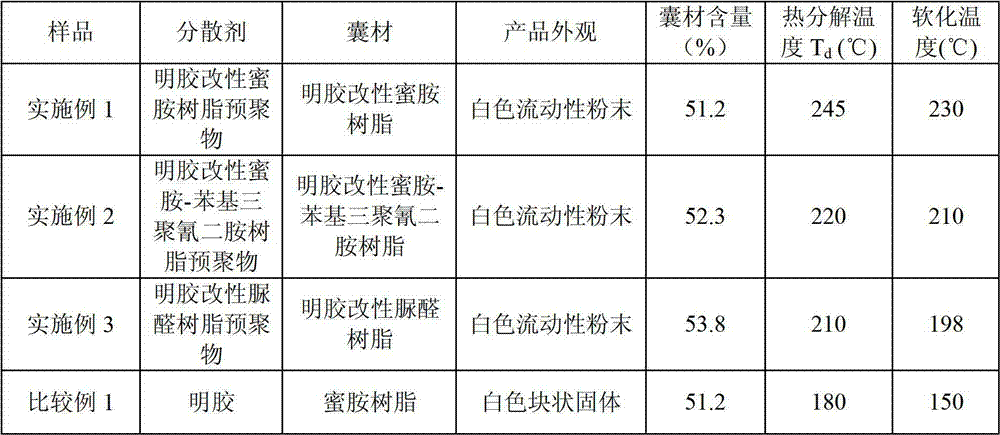

Examples

Embodiment 1

[0036] 1. Prepolymer synthesis: Add 1.5g gelatin, 7.5g melamine, 9.7g formaldehyde solution with a mass concentration of 37% and 70.0g water to a 250ml three-necked flask equipped with a thermometer, a stirrer and a reflux condenser, and use a mass concentration of 10 % sodium hydroxide solution to adjust the pH value to 8.5, raise the temperature to 80°C, keep the reaction solution transparent for 0.5 hours to prepare a gelatin-modified melamine resin prepolymer solution, and cool it down to room temperature for later use.

[0037] 2. Emulsification and dispersion: Add 200.0g of water and gelatin-modified melamine resin prepolymer solution to a 500ml beaker in turn, turn on the homogeneous emulsifier (model ESR, Shanghai Specimen Model Factory), add 12.0g of jasmine concentrated essence (Shanghai Linpa Perfume Co., Ltd.), emulsified and dispersed at room temperature for 40 minutes to prepare a water-dispersed flavor emulsion for future use.

[0038] 3. Microcapsule coating: A...

Embodiment 2

[0040] 1. Prepolymer synthesis: Add 1.3g gelatin, 6.0g melamine, 2.0g phenylmelamine, 10.4g formaldehyde with a mass concentration of 37% to a 250ml three-neck flask equipped with a thermometer, agitator and reflux condenser Aqueous solution and 70.0g water, adjust the pH value to 7.5 with sodium bicarbonate, heat up to 85°C, the reaction solution becomes transparent and then keep it warm for 0.5 hours to prepare gelatin modified melamine-phenylmelamine resin prepolymer solution , down to room temperature for later use.

[0041] 2. Emulsification and dispersion: Add 200.0g of water and gelatin modified melamine-phenylmelamine resin prepolymer solution in sequence to a 500ml beaker, turn on the homogeneous emulsifier (model ESR, Shanghai specimen model factory), add 12.0 g of jasmine with concentrated essence (Shanghai Linpa Perfume Co., Ltd.), emulsified and dispersed at room temperature for 40 minutes to obtain a water-dispersed essence emulsion, which is set aside.

[0042]...

Embodiment 3

[0044] 1. Prepolymer synthesis: Add 1.5g gelatin, 5.5g melamine, 2.5g urea, 12.5g formaldehyde solution with a mass concentration of 37% and 75.0g water to a 250ml three-necked flask equipped with a thermometer, a stirrer and a reflux condenser. Use sodium carbonate to adjust the pH value to 8.0, raise the temperature to 75°C, and keep the reaction solution for 0.5 hours after the reaction solution becomes transparent to prepare a gelatin-modified urea-formaldehyde resin prepolymer solution, which is lowered to room temperature for later use.

[0045] 2. Emulsification and dispersion: Add 220.0g of water and gelatin-modified urea-formaldehyde resin prepolymer solution in sequence to a 500ml beaker, turn on the homogeneous emulsifier (model ESR, Shanghai Specimen Model Factory), add 12.0g of jasmine concentrated essence (Shanghai Lin Pa Perfume Co., Ltd.), emulsified and dispersed at room temperature for 40 minutes to prepare a water-dispersed flavor emulsion for later use.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com