A brick-concrete composite wall and its construction method

A construction method and composite wall technology, applied in the direction of walls, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve the problem of unreliable fixing of facing bricks, limited construction methods, and full mortar To solve problems such as low strength, achieve the effect of improving construction efficiency, improving safety, and bonding firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

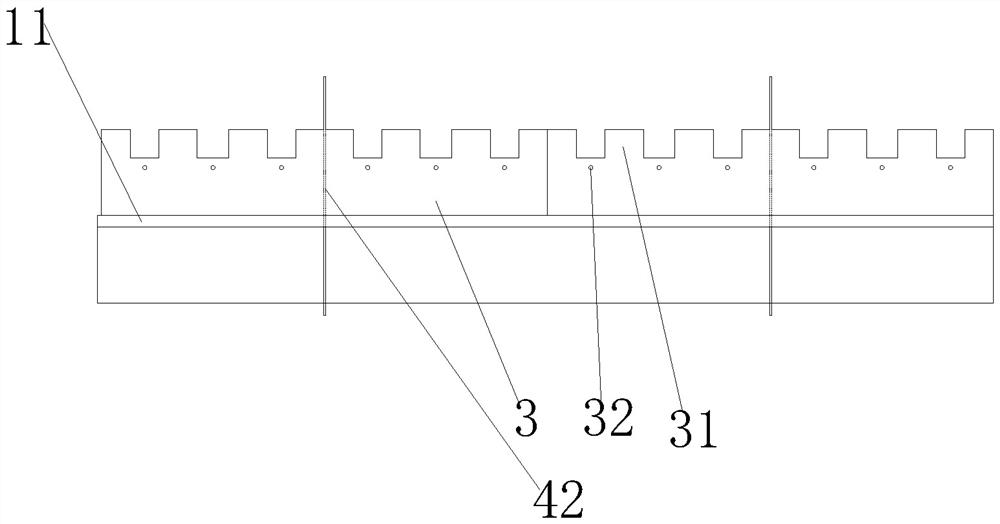

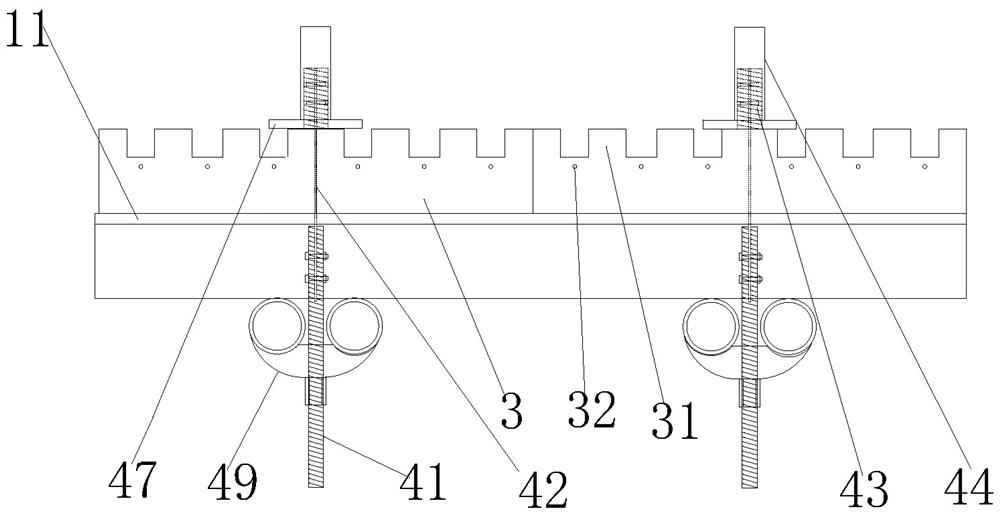

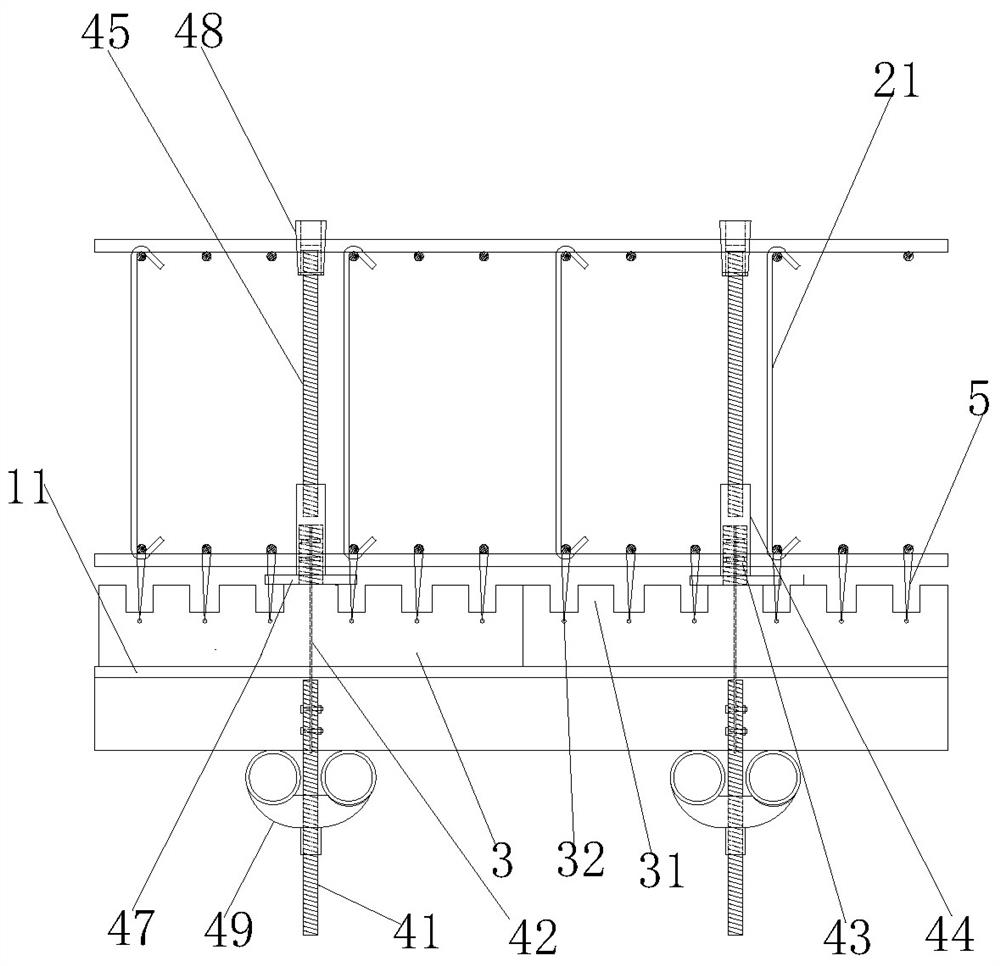

[0052] like Figure 7 As shown, a brick-concrete composite wall is used for building side walls or building roofs, including a cast-in-place concrete layer 2 and a face brick layer 3 adhered to one or both surfaces of the cast-in-place concrete layer 2 to form a face brick layer 3 Each face brick is connected with the wall reinforcement cage 21 in the cast-in-place concrete layer 2 respectively; when an earthquake occurs, the concrete part of the cast-in-place concrete layer 2 may be damaged, but the wall reinforcement cage 21 will remain intact. If the face brick is connected to the wall reinforcement cage 21, it can be guaranteed that the face brick will not fall off easily during an earthquake. In actual use, ceilings such as building ceilings can adopt a wall body with one facing brick layer 3 , and the facing brick layer 3 is arranged under the ceiling, while those antique buildings or building side walls can adopt a wall body with two facing brick layers 3 .

[0053] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com