Fiber composite material imitating structure and function of scales of coelacanth

A fiber composite material and technology for coelacanth, which is applied in the field of fiber composite materials imitating the structure and function of coelacanth scales, can solve the problems of poor strength, difficulty in finding an effective method to improve interlayer toughness, and single arrangement structure. To achieve the effect of changing the propagation path, diversifying the fiber arrangement, and improving the impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

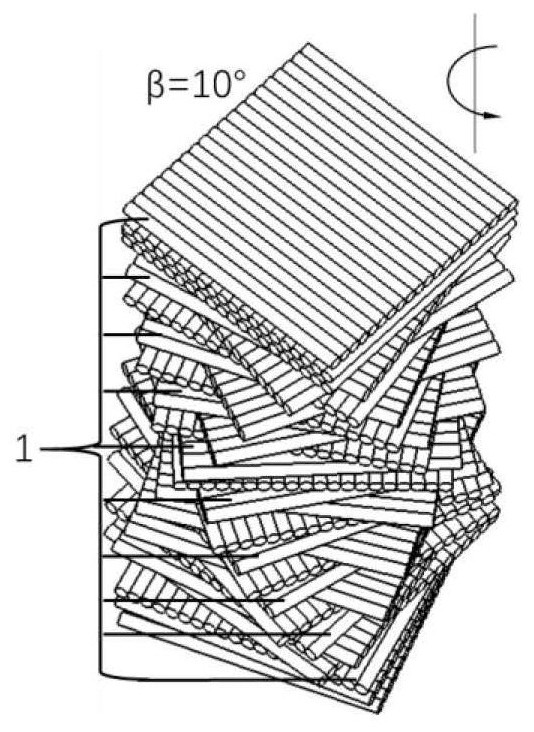

[0067]Such asFigure 2A ,2bAs shown in 2C, the present embodiment discloses a fiber composite material of the imitation cavity pepperfish scale structure and function, such asfigure 1 As shown, the layoff structure of the fiber composite material of the imitation cavity ratcarflake scale structure and function is used in a double helical laminated paving structure based on cavine fish scales.

[0068]The fibrous composite of the imitation cavity ratcaqui flakes and functions is pressed back by two sets of spiral fiber resin layers, wherein:

[0069]The second fiber resin layer 2 in the first fiber resin layer 1 and the second set of spiral fiber resin layer structures in the first group of spiral fiber resin layers is formed by unidirectional fiber pre-dip infiltration resins;

[0070]In the first set of spiral fiber resin layers, in the center line perpendicular to the center of the first fiber resin layer 1, the first fiber resin layer 1 rotates the same first rotation angle β from the top ...

Embodiment 2

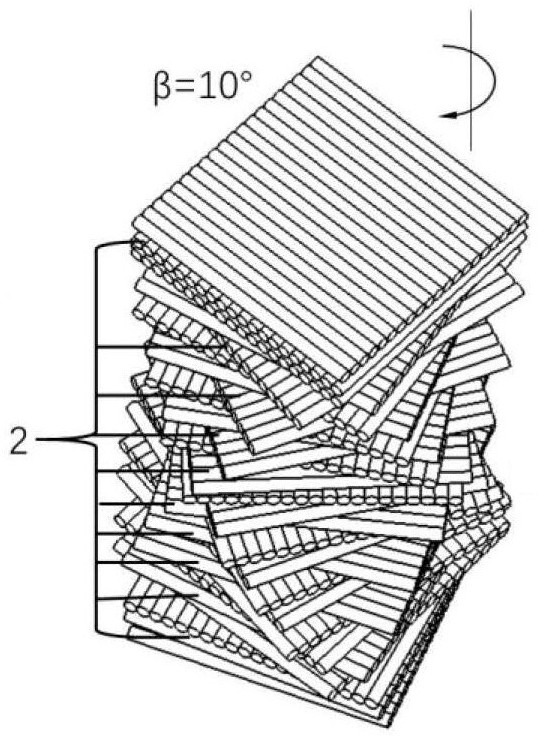

[0076]Such asFigure 3A ,3bAs shown in 3C, the second disclosure of which is disclosed a fiber composite material of the imitation cavity ratca-like scales structure and function, such asfigure 1 As shown, the layoff structure of the fiber composite material of the imitation cavity ratcarflake scale structure and function is used in a double helical laminated paving structure based on cavine fish scales.

[0077]The fibrous composite of the imitation cavity ratcaqui flakes and functions is pressed back by two sets of spiral fiber resin layers, wherein:

[0078]The second fiber resin layer 2 in the first fiber resin layer 1 and the second set of spiral fiber resin layer structures in the first group of spiral fiber resin layers is formed by unidirectional fiber pre-dip infiltration resins;

[0079]In the first set of spiral fiber resin layers, in the center line perpendicular to the center of the first fiber resin layer 1, the first fiber resin layer 1 rotates the same first rotation angle β f...

Embodiment 3

[0085]Such asFigure 4A ,4bAs shown in 4C, the third embodiment discloses a fiber composite material for imitation cavity pepperfish slats and functions, such asfigure 1 As shown, the layoff structure of the fiber composite material of the imitation cavity ratcarflake scale structure and function is used in a double helical laminated paving structure based on cavine fish scales.

[0086]The fibrous composite of the imitation cavity ratcaqui flakes and functions is pressed back by two sets of spiral fiber resin layers, wherein:

[0087]The second fiber resin layer 2 in the first fiber resin layer 1 and the second set of spiral fiber resin layer structures in the first group of spiral fiber resin layers is formed by unidirectional fiber pre-dip infiltration resins;

[0088]In the first set of spiral fiber resin layers, in the center line perpendicular to the center of the first fiber resin layer 1, the first fiber resin layer 1 rotates the same first rotation angle β from the top and downward.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com