Enhanced additive process and mold strengthening method based on arc fuse

An additive process and fuse technology, applied in additive processing, manufacturing tools, furnaces, etc., can solve the problems of arc fuse stripping, insufficient strength in the additive area, etc., to reduce residual stress, uniform node distribution, improve The effect of strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

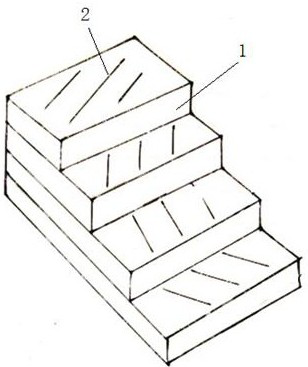

[0026] For new molds, additive strengthening areas can be reserved locally in advance, and then this method can be used for additive strengthening treatment; for failed molds, after the failed parts are cleaned out, this method can be used for additive strengthening treatment.

[0027] In the failure mold, for large molds, arc fuse additive strengthening is only required in the local area where wear occurs, while for small molds, arc fuse additive reinforcement can be performed on the entire mold surface. In this specific embodiment, tempering heat treatment is also performed on the mold after the arc fuse additive strengthening to obtain stable tempered martensite, so as to achieve the effect of improving the stability of the structure, so that the mold does not occur during use. With the transformation of the structure, its geometric size and performance tend to be stable, and at the same time, it can eliminate internal stress and improve toughness. The arc fuse additive pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com