Web frame for concrete organization

A concrete structure and skeleton technology, applied in the direction of structural elements, building reinforcements, building components, etc., can solve problems such as difficult to work together to resist pressure, hidden dangers in engineering quality, etc., achieve fast construction speed, save labor, and improve bearing strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

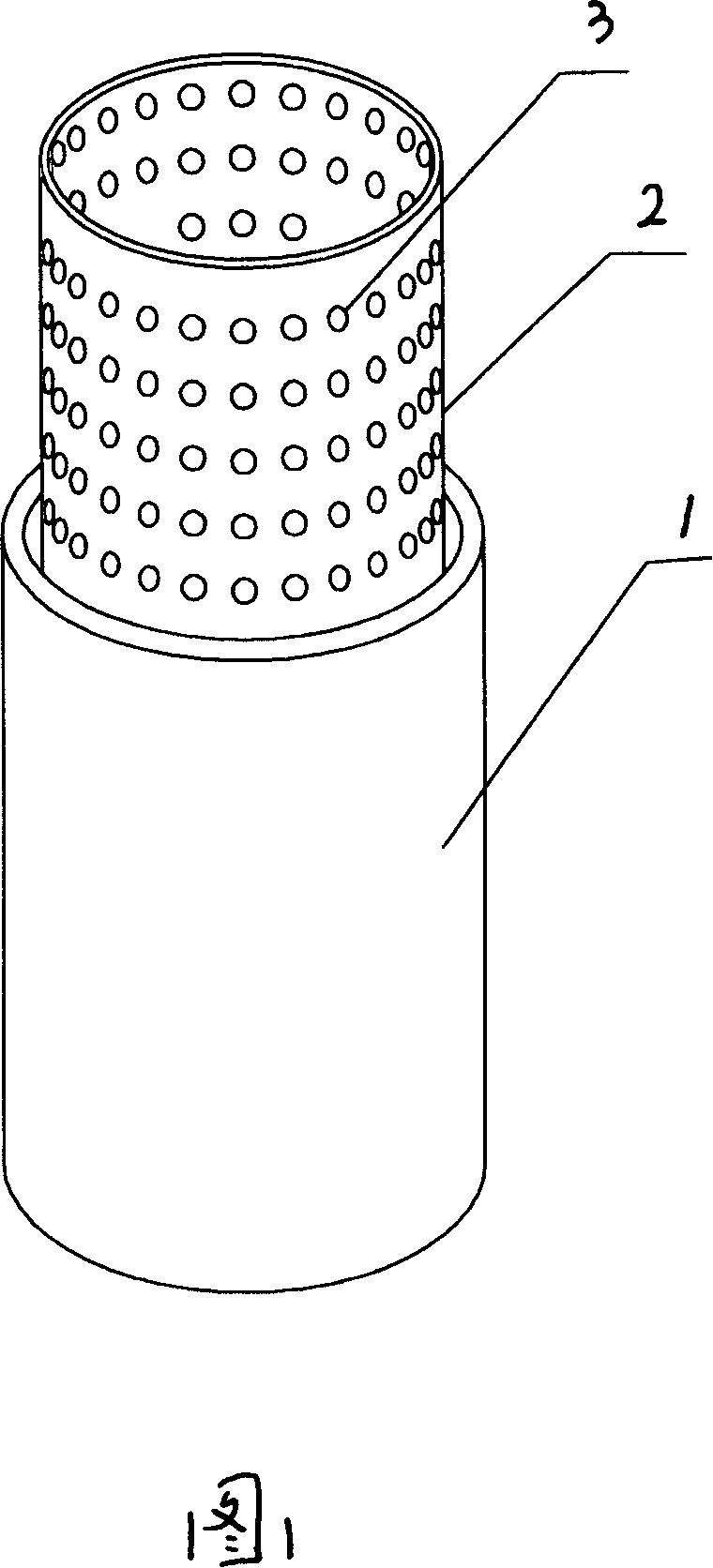

[0014] In Fig. 1, the present invention is provided with steel pipe 2, and the pipe wall of steel pipe 2 is arranged with small hole 3, and the steel pipe 2 that is arranged with small hole 3 on the pipe wall is in the process of pouring in concrete column 1, and concrete passes through the pipe. The small holes 3 on the wall tightly combine the steel pipe 2 and the concrete column 1 to form an inseparable one. The steel pipe 2 with the small holes 3 on the pipe wall plays a role in strengthening the skeleton. The steel pipe 2 with small holes 3 arranged on the wall bears high-strength horizontal and vertical pressure at the same time. Therefore, this structure not only has the functions of high pressure (tensile) strength, resistance to shear force, torsion force and earthquake resistance, but also the structure Simple, can speed up construction, save raw materials, save labor, not affected by climate temperature, fire prevention, aging resistance, corrosion resistance, and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com