A fiber composite material imitating the structure and function of lobster cuticle

A technology of fiber composite materials and cuticles, applied in the direction of layered products, synthetic resin layered products, vehicle parts, etc., can solve problems such as poor strength, single laying structure, and difficulty in finding effective ways to improve crack resistance. Achieve the effect of improving impact resistance and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

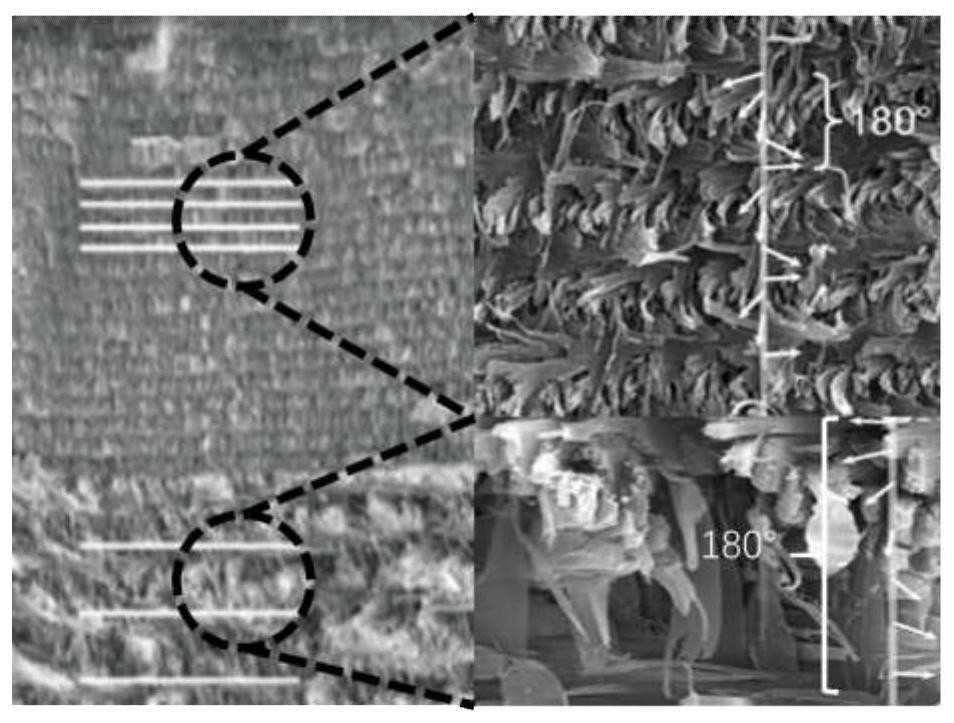

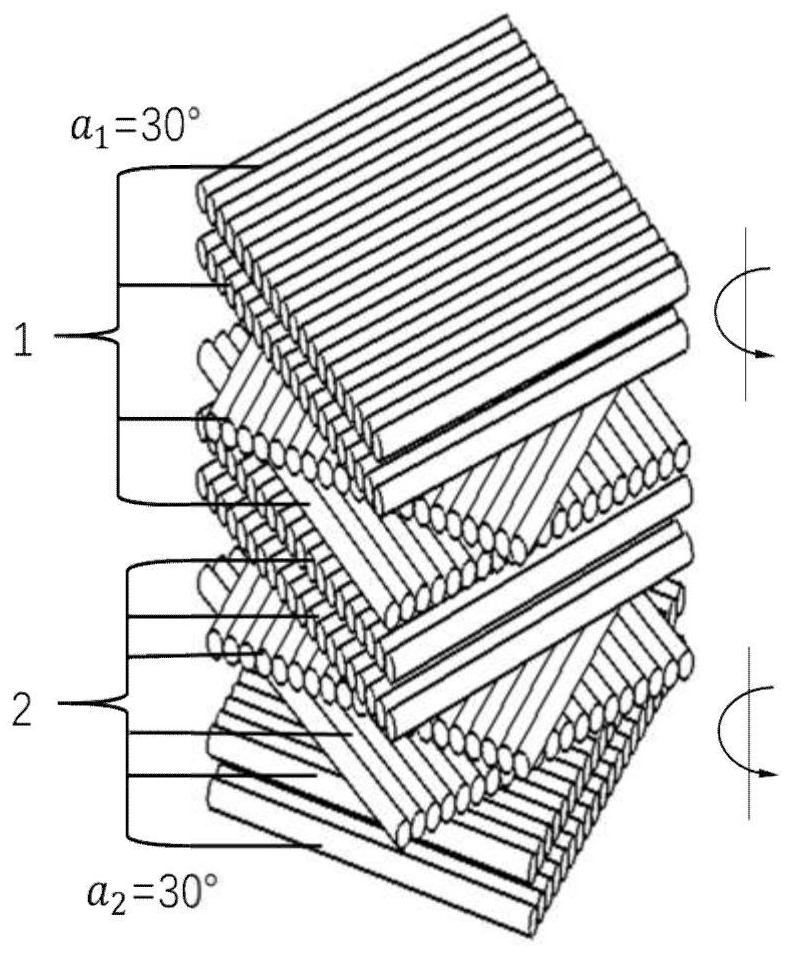

[0056] This example 1 discloses a fiber composite material imitating the structure and function of lobster cuticle. The bionic arrangement structure fiber composite material of the present invention is derived from such as figure 1 The non-linear rotation angle helical fiber structure of the cuticle of the lobster is shown, and the bionic fiber layout structure shown in Figure 2 is obtained by design, wherein: in Figure 2, the rotation angle x of the helical fiber resin layer satisfies the helix-oscillation function In this example, a=±30° and ±45° biomimetic arrangement structure of high-strength crack-resistant fiber composite material is formed by laying up helical fiber resin layers according to the helical angle of the helical-oscillating function.

[0057] Wherein, taking the center line perpendicular to the center of the spiral fiber resin layer as the axis, the first group of spiral fiber resin layers takes 4 layers as a rotation period, and the second group of spiral...

Embodiment 2

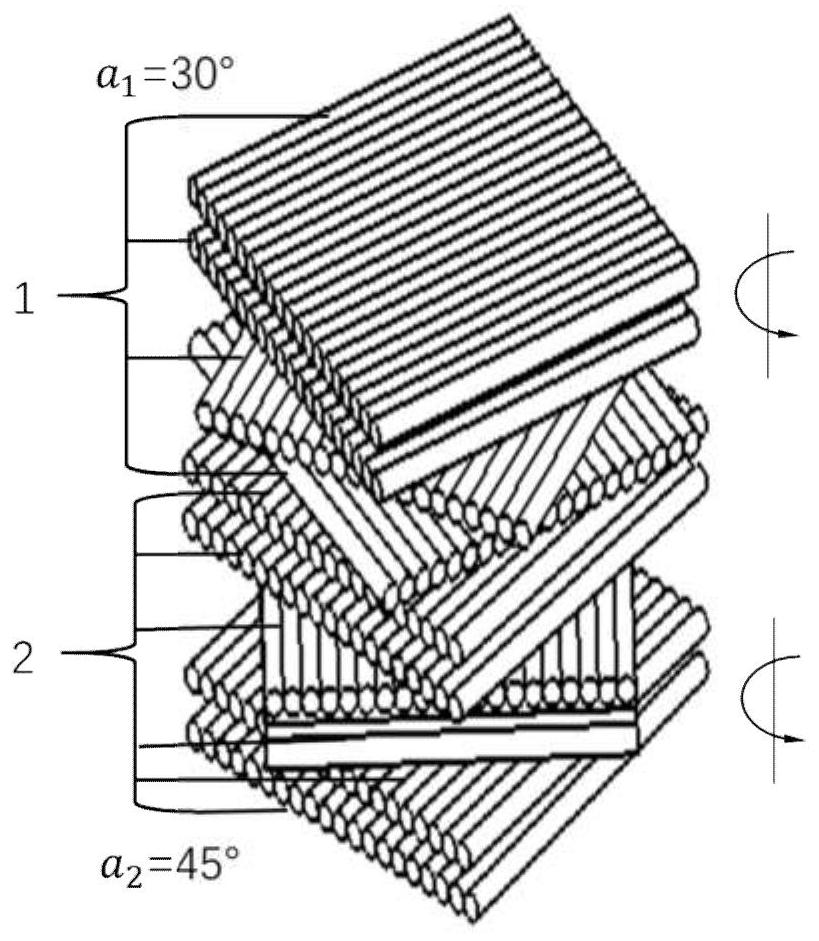

[0060] Example 2 discloses a fiber composite material imitating the structure and function of lobster cuticle. The bionic arrangement structure fiber composite material of the present invention is derived from such as figure 1 The non-linear rotation angle helical fiber structure of the cuticle of the lobster is shown, and the bionic fiber arrangement structure shown in Figure 3 is obtained by design, wherein: in Figure 3, the rotation angle y of the helical fiber resin layer satisfies the helical-increasing function b=±10° and ±15° in this example. The high-strength and anti-crack fiber composite material of the bionic layout structure is formed by stacking helical fiber resin layers according to the helical angle of the helical-increasing function.

[0061] Wherein, taking the center line perpendicular to the center of the spiral fiber resin layer as the axis, the first group of spiral fiber resin layers takes 4 layers as a rotation period, and the second group of spiral f...

Embodiment 3

[0064] Example 3 discloses a fiber composite material imitating the structure and function of lobster cuticle. The bionic arrangement structure fiber composite material of the present invention is derived from such as figure 1 The non-linear rotation angle helical fiber structure of the cuticle of the lobster is shown, and the bionic fiber arrangement structure shown in Figure 4 is obtained by design, wherein: in Figure 4, the rotation angle z of the helical fiber resin layer satisfies the helix-exponential function z i =c i (1≤i≤6, 2≤c≤3, i is an integer, zi=0), c=2 and 3 in this example. The high-strength and anti-crack performance fiber composite material of the bionic layout structure is formed by laying up helical fiber resin layers according to the helical-exponential function helical angle.

[0065] Wherein, taking the center line perpendicular to the center of the spiral fiber resin layer as the axis, the first group of spiral fiber resin layers takes 4 layers as a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com