Method for cleaning petrochemical engineering pipeline with ice slurry

A technology of petrochemical and ice slurry, which is applied in the field of cleaning petrochemical pipelines with ice slurry, which can solve the problems of low pigging efficiency, high pipeline risk, and heavy manual cleaning workload, etc., and achieves the effect of high cleaning efficiency and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

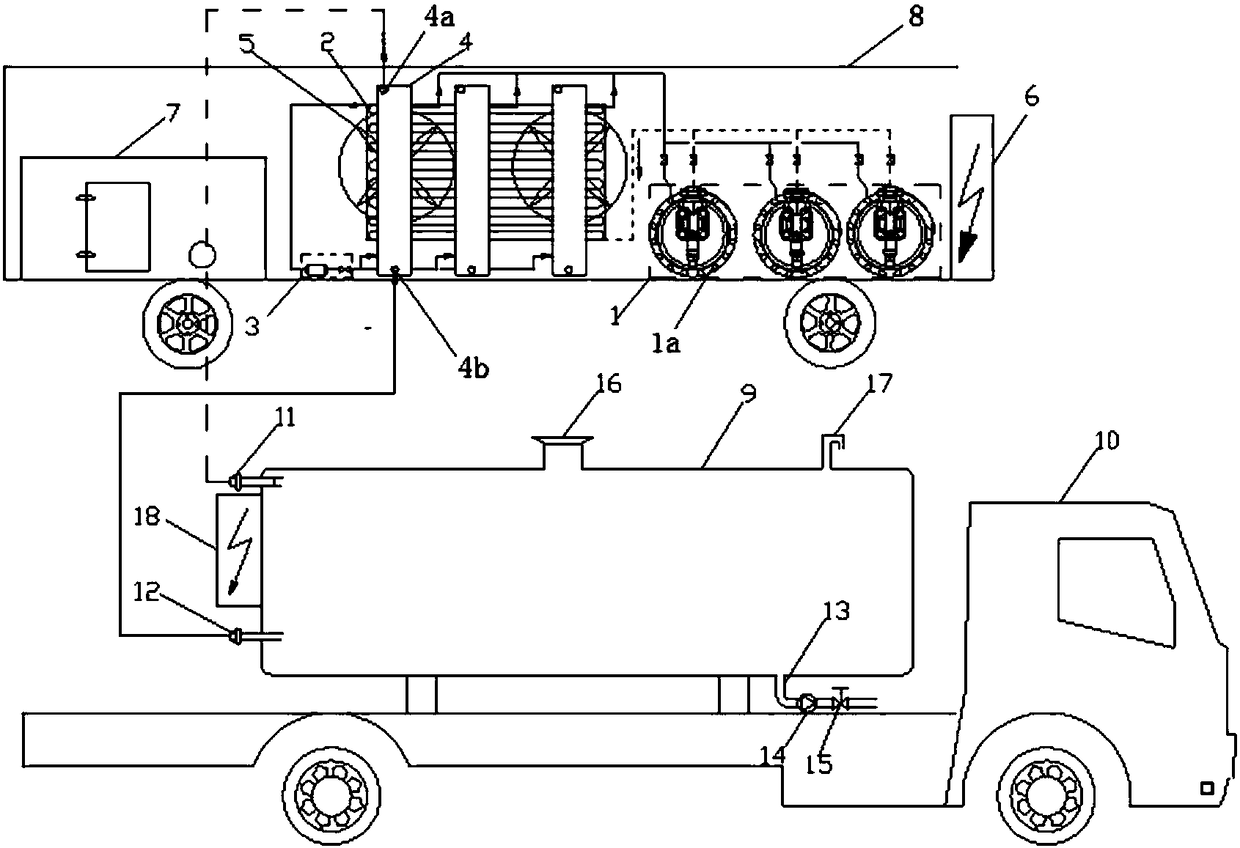

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

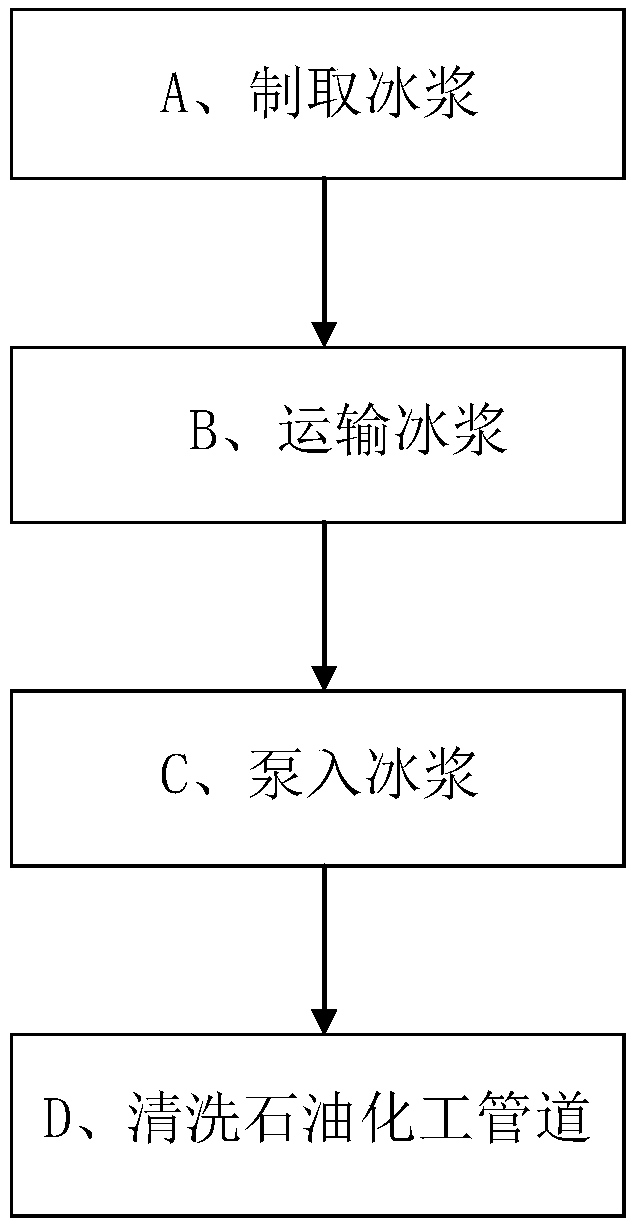

[0036] Such as figure 1 Shown, adopt the method for ice slurry cleaning petrochemical pipeline to comprise the steps:

[0037] A. Preparation of ice slurry: the ice slurry production unit and ice slurry storage unit produce high-concentration ice slurry during non-operating hours;

[0038] B. Transport the prepared ice slurry storage unit to the petrochemical pipeline to be cleaned;

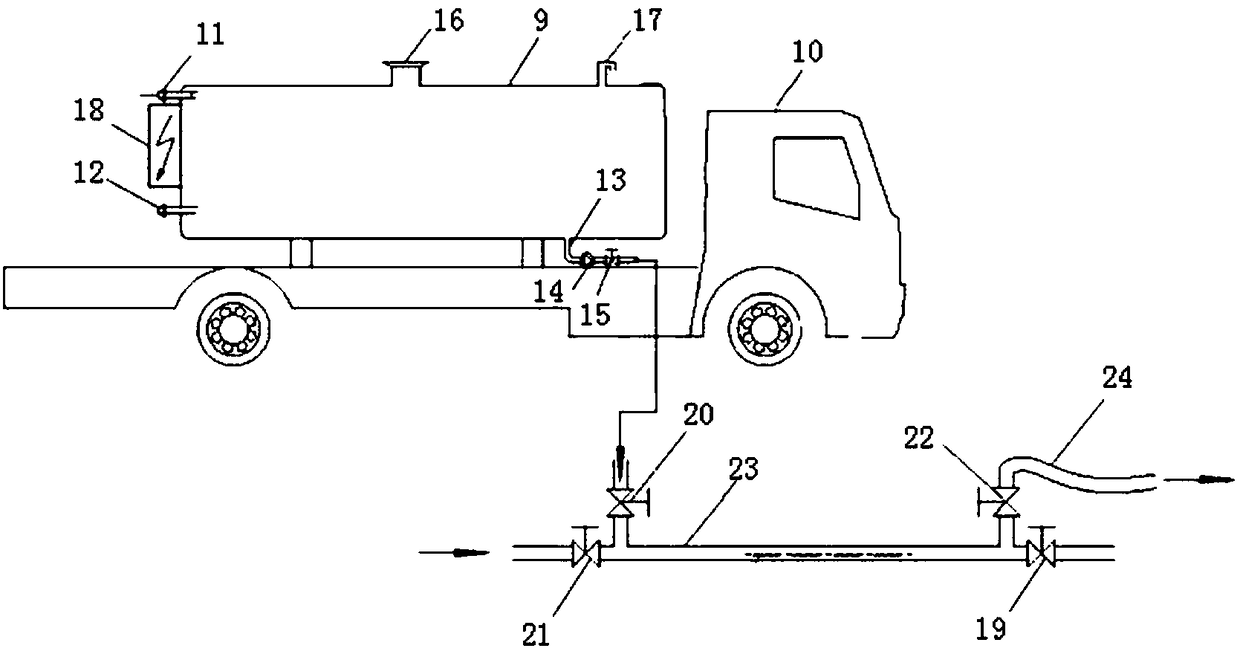

[0039] C. The high-concentration ice slurry is injected into the petrochemical pipeline 23 to be cleaned from the valve interface of the petrochemical pipeline 23 by using the ice slurry delivery pump 14, so that the high-concentration ice slurry forms a solid-like icicle in the petrochemical pipeline 23 and have liquidity;

[0040] D. Use the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com