ZSM-5 molecular sieve and preparation method thereof

A ZSM-5, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of complex surfactants and cumbersome processes, achieve difficult agglomeration and improve utilization. rate, the effect of reducing the internal diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present embodiment provides a kind of preparation method of ZSM-5 molecular sieve, it comprises the following steps:

[0057] Get 1.45g ammonium fluoride (content≧96.0wt%), add 40.10g deionized water, after dissolving, add 2.45g aluminum sulfate (content≧99.0wt%), 14.61g tetrapropyl ammonium hydroxide (content 25.0wt%) %), after mixing uniformly, add 23.67g silica gel (content 94.0wt%), stir well, make gel reaction mixture;

[0058] The gel reaction mixture was aged at 80°C for 16 hours;

[0059] Put the above-mentioned gel reaction mixture into a reaction kettle, put the reaction kettle into an oven, crystallize at 140° C. for 28 hours, filter, wash and dry to obtain ZSM-5 molecular sieve.

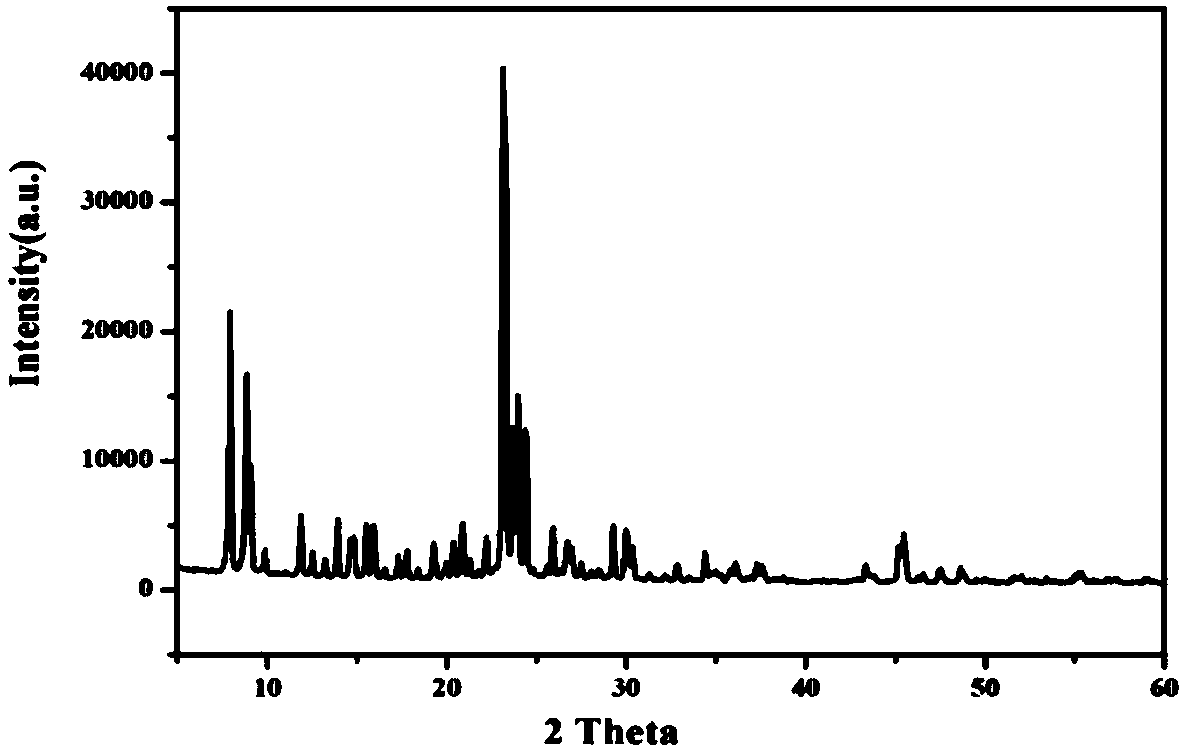

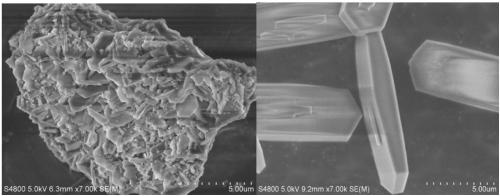

[0060] The obtained ZSM-5 molecular sieve is characterized by XRD technology, and the obtained XRD pattern is as follows figure 1 As shown, it is characterized by SEM, and the SEM picture is obtained as figure 2 As shown, the measured silicon-aluminum ratio of the above-men...

Embodiment 2

[0062] The present embodiment provides a kind of preparation method of ZSM-5 molecular sieve, it comprises the following steps:

[0063] Take 9.72g sodium fluoride (content≧99.0wt%), add 81.00g deionized water, after dissolving, add 5.01g aluminum sulfate (content≧99.0wt%), 9.57g tetrapropylammonium bromide (content≧99.0 wt%), after mixing evenly, add 47.34g silica gel (content 94.0wt%), stir evenly, make the gel reaction mixture;

[0064] The gel reaction mixture was aged at 50°C for 24 hours;

[0065] Put the above gel reaction mixture into a reaction kettle, put the reaction kettle into an oven, crystallize at 180° C. for 20 hours, filter, wash and dry to obtain ZSM-5 molecular sieve.

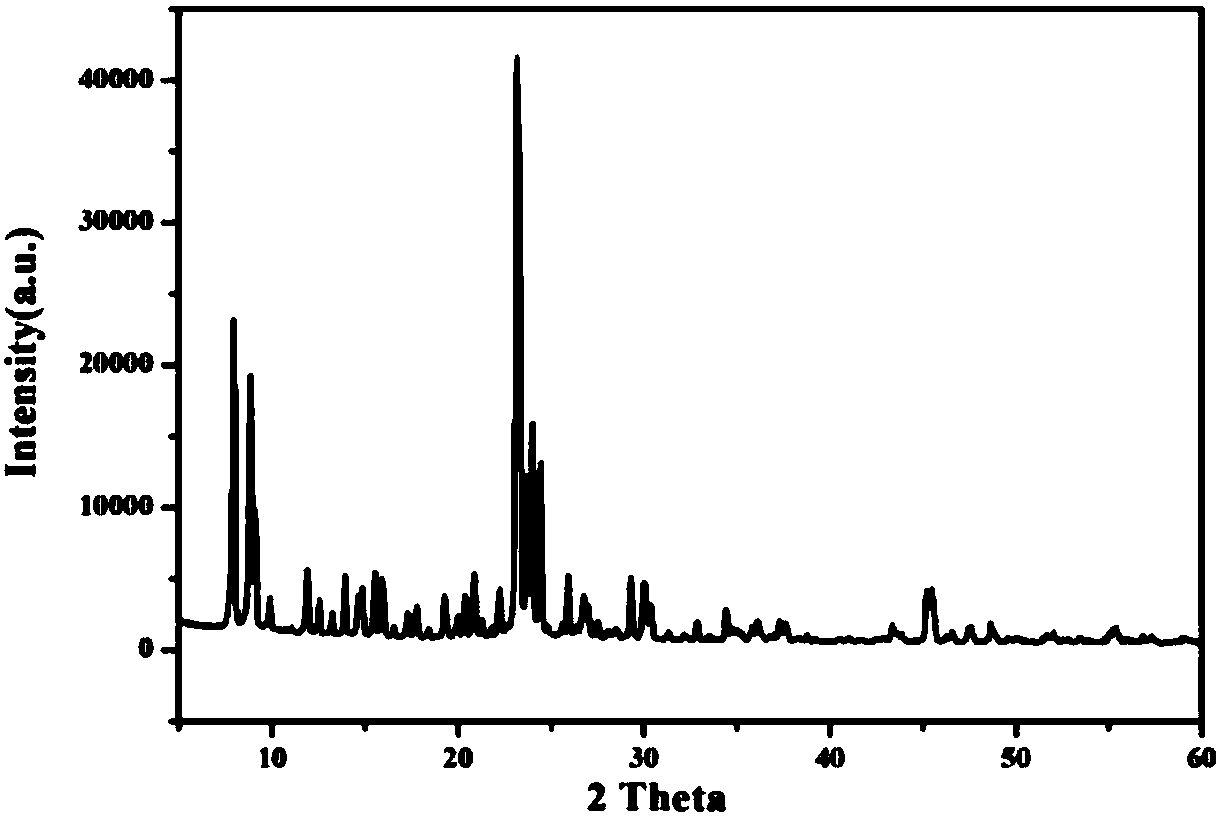

[0066] The obtained ZSM-5 molecular sieve is characterized by XRD technology, and the obtained XRD pattern is as follows image 3 As shown, it is characterized by SEM, and the SEM picture is obtained as Figure 4 As shown, the measured silicon-aluminum ratio of the above-mentioned ZSM-5 i...

Embodiment 3

[0068] The present embodiment provides a kind of preparation method of ZSM-5 molecular sieve, it comprises the following steps:

[0069] Take 7.73g hydrofluoric acid (content≧40.0wt%), add 79.89g deionized water, after dissolving, add 4.98g aluminum sulfate (content≧99.0wt%), 9.60g tetrapropylammonium bromide (content≧99.0 wt%), after mixing uniformly, add 47.42g white carbon black (content 94.0wt%), stir well, obtained gel reaction mixture;

[0070] The gel reaction mixture was aged at 60°C for 22 hours;

[0071] Put the above gel reaction mixture into a reaction kettle, put the reaction kettle into an oven, crystallize at 190° C. for 18 hours, filter, wash and dry to obtain ZSM-5 molecular sieve.

[0072] The obtained ZSM-5 molecular sieve was characterized with a zeolite, and it was measured that the silicon-aluminum ratio of the above-mentioned ZSM-5 was 97.4, the relative crystallinity was 98%, and the morphology was thin-plate type.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com