A method of synthesizing a NaY molecular sieve and the synthesized NaY molecular sieve

A technology of molecular sieves and mixtures, applied in the direction of octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the process complexity and uncontrollable product properties, high viscosity cannot improve the solid content of the system, and the utilization rate of silicon sources Low-level problems, to achieve the effect of improving single-pot utilization, low cost, and improving single-pot yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

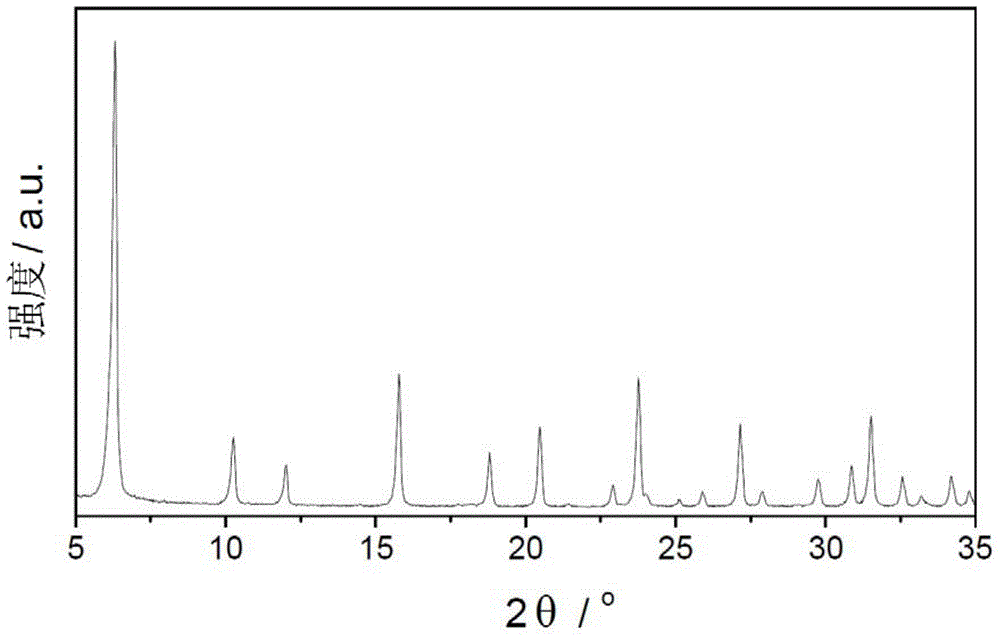

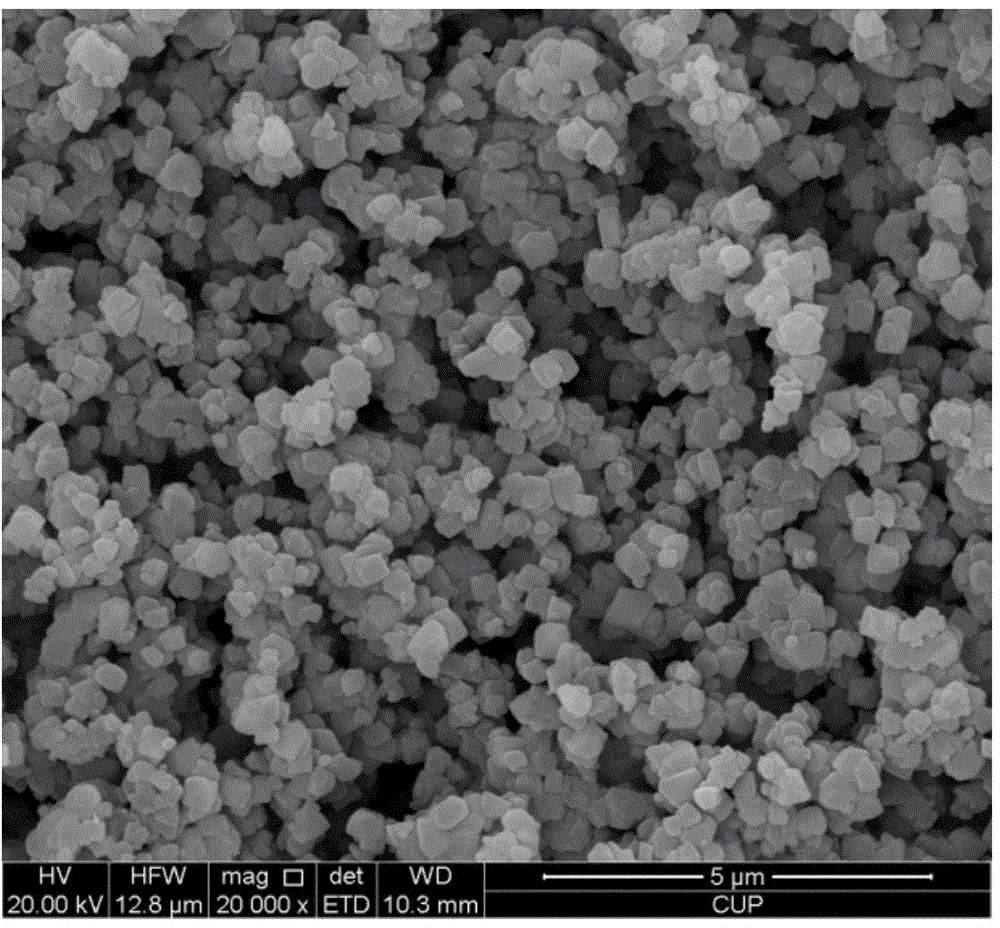

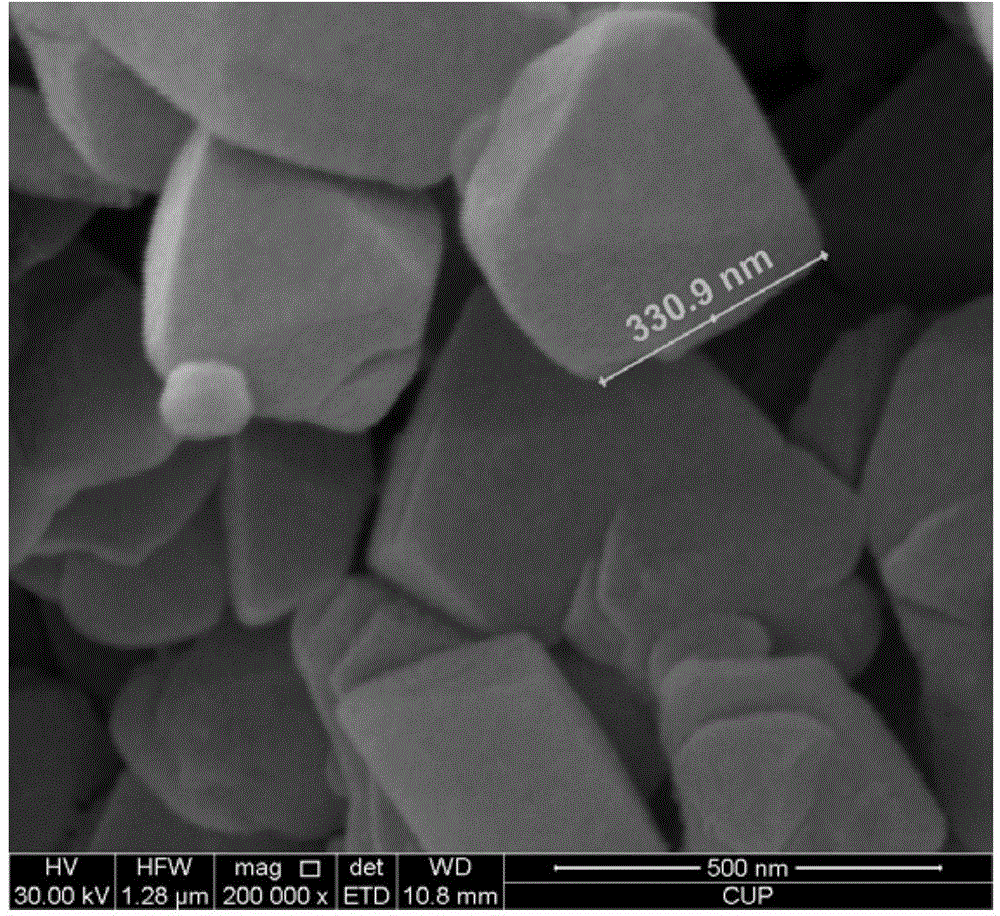

Embodiment 1

[0073] First, weigh 57.81g of water glass and put it in a beaker, then weigh 8.81g of sodium hydroxide solid (Beijing Century Hongxing Chemical Co., Ltd., analytically pure) and put it in a beaker, mix the two evenly, and put them at room temperature (27 ℃) and stirred for 2 hours to prepare a highly active hydrated sodium silicate solution; then add 54.11g deionized water and 3.12g sodium metaaluminate (Tianjin Jinke Chemical Research Institute, Al 2 o 3 The content is 45wt%, Na 2 The content of O is 41wt%), stir and mix evenly, and age at room temperature (27°C) for 36 hours to prepare the directing agent. The molar ratio of the composition in the directing agent is 15.3Na 2 O: Al 2 o 3 :19SiO2 2 :376H 2 O.

[0074] Weigh 5.00g of sodium hydroxide solid and dissolve it in 45g of deionized water, stir to fully dissolve to prepare an alkaline solution, then weigh 42.54g of coarse-pore microsphere silica gel and add it to the alkaline solution, and stir at a constant temp...

Embodiment 2

[0076] The preparation of directing agent and various raw material sources are all the same as embodiment 1

[0077] Weigh 2.50g of sodium hydroxide solid and dissolve it in 24g of deionized water, stir to fully dissolve to prepare an alkaline solution, then weigh 15.01g of coarse-pore microsphere silica gel and add it to the alkaline solution, and stir at a constant temperature of 10°C After 4 hours, the highly active hydrated silica gel was prepared, and then 7.00 g of sodium metaaluminate was weighed into the high-activity hydrated silica gel. After stirring evenly, 37.79 g of the above-mentioned guiding agent was added, and the liquid-like solid-phase reaction gel was obtained by stirring evenly. , the total mass of the reaction gel mixture is 86.3g, and the ratio is 5.74Na 2 O: Al 2 o 3 :10.05SiO2 2 :73.02H 2 O, the solid content is 38.89%. Put it into a stainless steel reaction kettle lined with tetrachlorethylene, statically crystallize at 90°C for 60h, then filter...

Embodiment 3

[0079] The preparation of directing agent and various raw material sources are all the same as embodiment 1

[0080] Weigh 2.00g of sodium hydroxide solid and dissolve it in 20g of deionized water, stir to fully dissolve to prepare an alkaline solution, then weigh 16.21g of coarse-pore microsphere silica gel and add it to the alkaline solution, and stir at a constant temperature of 30°C After 2.5 hours, high-activity hydrated silica gel was prepared, and then 8.00 g of sodium metaaluminate was weighed into the high-activity hydrated silica gel. After stirring evenly, 39.71 g of the above-mentioned guiding agent was added, and the liquid-like solid-phase reaction gel was obtained by stirring evenly. , the total mass of the reaction gel mixture is 83.91g, and the ratio is 3.31Na 2 O: Al 2 o 3 :8.76SiO2 2 :69.26H 2 O, the solid content is 41.17%. Put it into a stainless steel reaction kettle lined with tetrachlorethylene, statically crystallize at 105°C for 32h, then filter,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com