Liquid float polishing method taking non Newtonian power law fluid as polishing medium

A power-law fluid and polishing medium technology, applied in the field of ultra-smooth surface polishing of optical components, can solve the problems of large equipment investment, low polishing efficiency, low removal efficiency, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

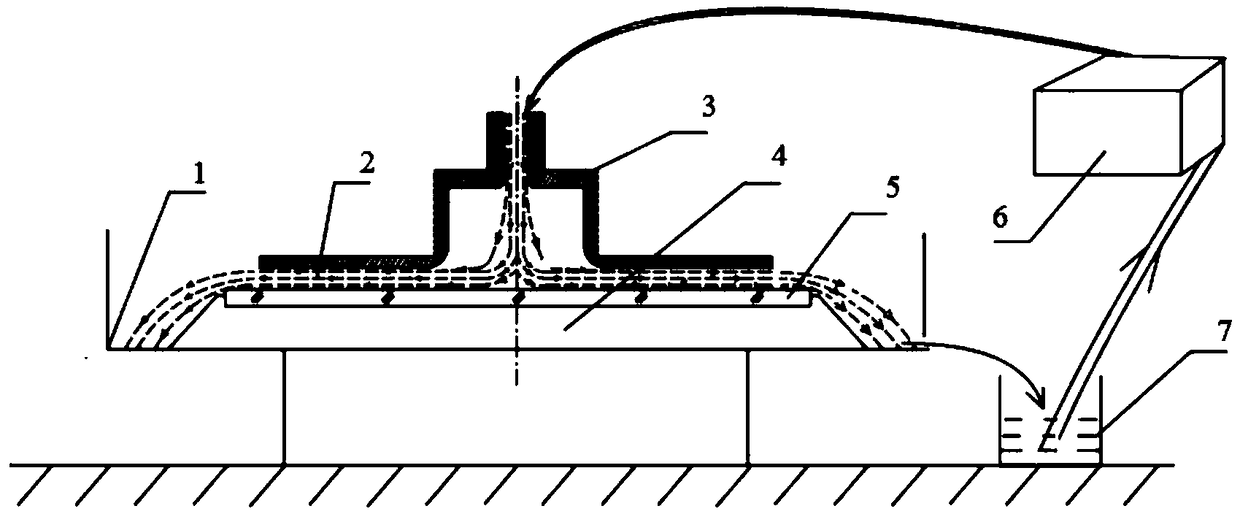

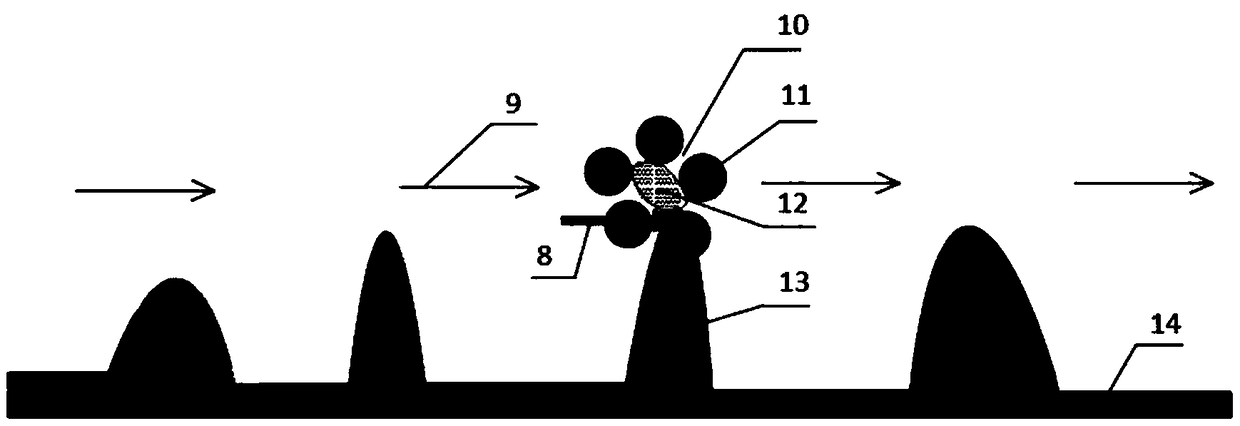

Method used

Image

Examples

Embodiment 1

[0028] Configure a certain amount of non-Newtonian power law fluid shear thickening polishing liquid, set the grinding head pressure as M=40kg, the mass fraction wt% of cerium oxide in the polishing liquid (CeO 2 )=14%, the mass fraction wt% of silicon dioxide (SiO 2 )=9%, the remainder is polyethylene glycol; the SiO 2 The average particle size is about d 1 =12nm, CeO 2 The average particle size is d 2 =5um, the inlet pressure is set to 0.5MPa. The workpiece is made of K9 glass, and the diameter of the workpiece is D 工件 =150mm, the diameter of the polishing surface of the grinding head is D 磨头 =150mm, the polishing time of the workpiece is set to 3h (the time interval for measuring the surface of the workpiece is 1h). Use this method to polish, and use the newview8000 white light interferometer of ZYGO Company to detect the roughness of the workpiece surface for the initial and processed workpieces at different times.

[0029] see image 3 , image 3 (a) The picture ...

Embodiment 2

[0031] Configure a certain amount of non-Newtonian power law fluid shear thickening polishing liquid, set the grinding head pressure as M=40kg, the mass fraction wt% of cerium oxide in the polishing liquid (CeO 2 )=18%, the mass fraction wt% of silicon dioxide (SiO 2 )=9%, the remainder is polyethylene glycol. Use this method to size diameter D 工件 =150mm K9 glass for polishing.

Embodiment 3

[0033] When setting the dispersed phase silica mass fraction wt% (SiO 2 )=9%, abrasive cerium oxide mass fraction wt% (CeO 2 )=18%, the remainder is polyethylene glycol. The inlet pressure is set to P 入 =0.3MPa, the grinding head pressure M=34.3kg, the workpiece polishing time is set to 90min (the time interval for measuring the workpiece surface is 30min). The initial and processed workpieces at different times are tested with ZYGO's newview8000 white light interferometer to detect the surface roughness of the workpiece.

[0034] Here, 9 different points on the workpiece are selected for detection, and the test results are as follows: Figure 4 As shown, the initial roughness has a significant decline, and has reached saturation in the later stage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com