A kind of preparation method of water-based pigment dispersion and water-based ink

A technology of water-based pigments and dispersions, which is applied to inks, pigment pastes, household appliances, etc., and can solve the inevitable problems of shortening the storage time of pigment dispersions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

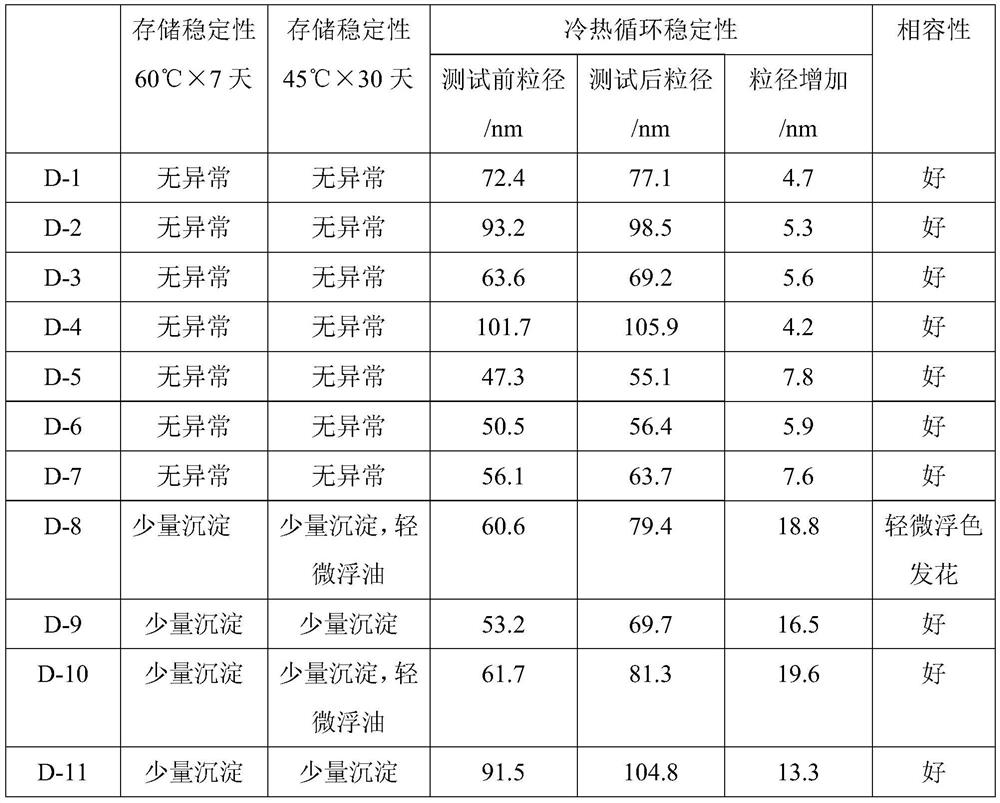

Examples

Embodiment 1

[0029] 4 parts of OP-10 and 1 part of emulsifier composed of sodium dodecylbenzenesulfonate, 2 parts of n-butanol, 50 parts of pigment carbon black, 5 parts of methacrylic acid, 15 parts of structural formula CH 2 =C(CH 3 )COO(CH 2 CH 2 O) 5.5 (CH 2 CHCH 3 O) 1.2 CH 3 Polyether monoacrylate, 50 parts of methyl methacrylate, 100 parts of butyl acrylate, and 10 parts of azobisisobutyronitrile were mixed, stirred at high speed to disperse evenly, and obtained an oil phase;

[0030] The above oil phase was gradually added to 320 parts of water stirred at high speed to obtain a transparent to translucent microemulsion; the temperature of the microemulsion was raised to 80 ° C for 10 hours under low speed stirring, and the temperature was lowered to below 50 ° C, and 0.05 parts of water-soluble aziridine was added Cross-linking agent, stirred for 4 hours, added ammonia water to adjust the pH to 7.5, and filtered through an 80-mesh filter to obtain a water-based pigment disper...

Embodiment 2

[0032] 4 parts of OP-10 and 1 part of emulsifier composed of sodium dodecylbenzenesulfonate, 1 part of ethylene glycol, 70 parts of iron oxide red, 5 parts of acrylic acid, 5 parts of hydroxypropyl methacrylate, 5 parts of structural formula CH 2 =C(CH 3 )COO(CH 2 CH 2 O) 6.7 CH 3 The polyether monoacrylate, 100 parts of styrene, and 5 parts of azobisisoheptanonitrile were mixed and stirred at high speed to disperse evenly to obtain an oil phase;

[0033]The above oil phase was gradually added to 350 parts of water stirred at high speed to obtain a transparent to translucent microemulsion; the microemulsion was heated to 60 ° C for 8 hours under low speed stirring, and the temperature was lowered to below 50 ° C, and 0.1 part of water-soluble carboimide was added cross-linking agent, stirred for 2 hours, added ammonia water to adjust the pH to 8.0, and filtered through an 80-mesh filter to obtain a water-based pigment dispersion, denoted as D-2.

Embodiment 3

[0035] Emulsifier consisting of 3.8 parts OP-10 and 1.2 parts sodium dodecylbenzenesulfonate, 0.5 parts propylene glycol, 50 parts ultramarine blue, 1 part acrylic acid, 4.5 parts hydroxypropyl methacrylate, 10 parts styrene, 40 parts Mix butyl acrylate and 2 parts of azobisisobutyronitrile, stir at high speed and disperse evenly to obtain an oil phase;

[0036] The above oil phase was gradually added to 120 parts of water stirred at high speed to obtain a transparent to translucent microemulsion; the microemulsion was heated to 80°C under low speed stirring for 8 hours, and the temperature was lowered to below 50°C, and 0.015 parts of water-soluble aziridine was added Cross-linking agent, stirred for 3 hours, added ammonia water to adjust the pH to 6.5, and filtered through an 80-mesh filter to obtain a water-based pigment dispersion, which was recorded as D-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com