Composite aluminum pipe G-shaped pipe and machining process thereof

A processing technology, a technology of composite aluminum, applied in the direction of pipeline heating/cooling, pipe/pipe joint/pipe fitting, pipeline protection, etc., can solve the problem of affecting the protective effect of coating layer on metal, etc. The effect of enhancing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

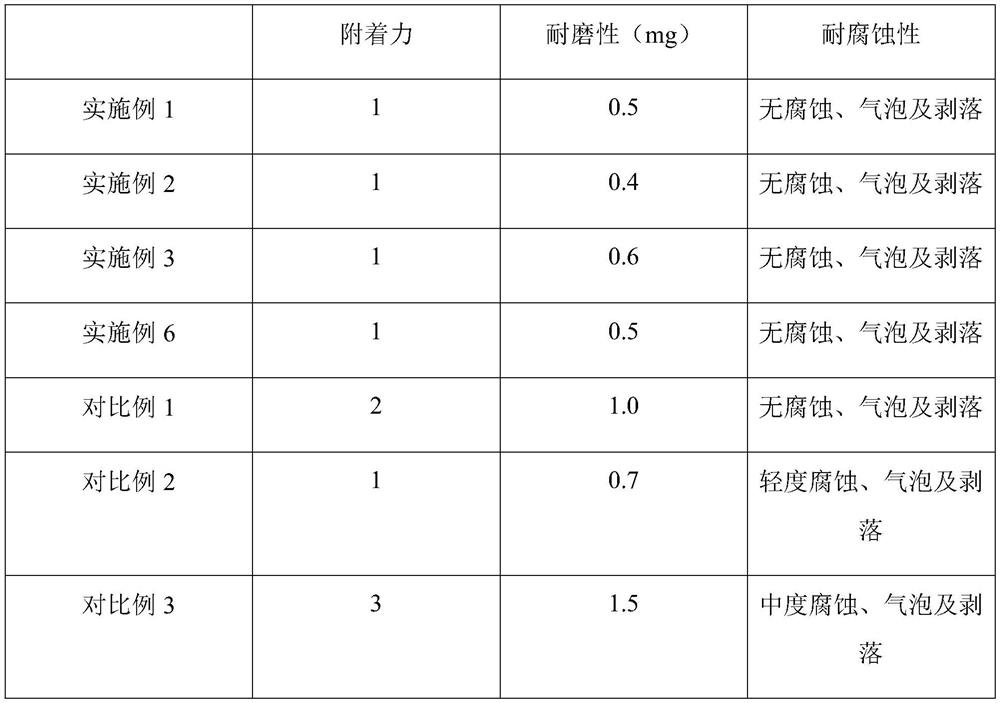

Examples

Embodiment 1

[0032] Example 1: S1: After mixing 5 parts of tetraethyl orthosilicate and 10 parts of ethanol evenly, add 10 parts of water, use hydrochloric acid solution to adjust the pH value of the solution to 3, react at 30°C for 1 hour, then After continuing to react for 2 hours, mix well with 10 parts of ethanol and 3 parts of silicone monomer, slowly add 10 parts of water, continue to use hydrochloric acid solution to adjust the pH value of the solution to 3, react at 70°C for 4 hours, add 1 part of sodium carbonate to neutralize React, detect the pH value of the solution, when it is greater than 7, filter the solution and distill under reduced pressure, it is a silicone copolymer;

[0033] S2: Dissolve 8 parts of bisphenol A epoxy resin in a mixed solution of 10 parts of xylene, cyclohexanone and n-butanol, add 12 parts of silicone copolymer, mix well, add 0.1 part of organic bismuth, and heat at 80 °C Reaction for 3h, vacuum distillation, is the modified epoxy resin;

[0034] S3: ...

Embodiment 2

[0039]Example 2: S1: After mixing 10 parts of tetraethyl orthosilicate and 15 parts of ethanol evenly, add 15 parts of water, use hydrochloric acid solution to adjust the pH value of the solution to 3, and react at 35°C for 1-2h, then at 50 After continuing to react for 2.5 hours at ℃, mix well with 15 parts of ethanol and 5 parts of organosilicon monomer, slowly add 15 parts of water, continue to use hydrochloric acid solution to adjust the pH value of the solution to 3, react at 75℃ for 5 hours, add 3 parts of carbonic acid Sodium neutralization reaction, detect the pH value of the solution, when it is greater than 7, filter the solution and distill under reduced pressure, it is a silicone copolymer;

[0040] S2: Dissolve 12 parts of bisphenol A epoxy resin in a mixed solution of 20 parts of xylene, cyclohexanone and n-butanol, add 20 parts of silicone copolymer, mix well, add 0.3 parts of organic bismuth, and heat at 85 °C After reacting for 3.5h, under reduced pressure dis...

Embodiment 3

[0046] Example 3: S1: After mixing 15 parts of tetraethyl orthosilicate and 20 parts of ethanol evenly, add 20 parts of water, use hydrochloric acid solution to adjust the pH value of the solution to 3, react at 40°C for 2 hours, and then at 50°C After continuing to react for 3 hours, mix well with 20 parts of ethanol and 8 parts of silicone monomer, slowly add 20 parts of water, continue to use hydrochloric acid solution to adjust the pH value of the solution to 3, react at 80°C for 6 hours, add 5 parts of sodium carbonate to neutralize React, detect the pH value of the solution, when it is greater than 7, filter the solution and distill under reduced pressure, it is a silicone copolymer;

[0047] S2: Dissolve 16 parts of bisphenol A epoxy resin in a mixed solution of 25 parts of xylene, cyclohexanone and n-butanol, add 24 parts of organic silicon copolymer, mix well, add 0.5 parts of organic bismuth, at 80- React at 90°C for 34 hours, and distill under reduced pressure to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com