Method for refining magnesium alloy grains by using Zn-Sr intermediate alloy

A technology for master alloys and magnesium alloys, which is applied in the fields of metal materials and metallurgy, and can solve the problems of poor grain efficiency of magnesium alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Under the melting conditions of flux or gas protection, AZ31(Mg-3Al-1Zn) magnesium alloy is melted in a crucible and then heated to 740°C, and Zn-58wt%Sr master alloy is added, and the amount of Sr added is 0.1% (weight percentage). After adding the Zn-58wt%Sr master alloy, keep the alloy melt at 740°C for 5-10 minutes, then stir the alloy melt, heat up to 720°C after stirring, and then use C 2 Cl 6 The refining agent is used for refining treatment for 5-10 minutes. After refining, stir the alloy melt and let it stand at 740°C for 10 minutes. After standing, remove the scum on the surface of the alloy melt to obtain a magnesium alloy melt with good refining effect.

Embodiment 2

[0026] Example 2: Under flux or gas shielded smelting conditions, AZ91 (Mg-9Al-1Zn) magnesium alloy is melted in a crucible and then heated to 740°C, and Zn-65wt%Sr master alloy is added, and the amount of Sr added is 0.05% (weight percent). After adding the Zn-65wt%Sr master alloy, keep the alloy melt at 740°C for 5-10 minutes, then stir the alloy melt, heat up to 730°C after stirring, and then use C 2 Cl 6The refining agent is used for refining treatment for 5-10 minutes. After refining, stir the alloy melt and let it stand at 740°C for 10 minutes. After standing, remove the scum on the surface of the alloy melt to obtain a magnesium alloy melt with good refining effect.

Embodiment 3

[0027] Example 3: Under flux or gas shielded smelting conditions, the ZA84 (Mg-8Zn-4Al) magnesium alloy is melted in a crucible and then heated to 740°C, and the Zn-72wt%Sr master alloy is added, and the amount of Sr added is 0.15% (percentage by weight). After adding the Zn-72wt%Sr master alloy, keep the alloy melt at 740°C for 5-10 minutes, then stir the alloy melt, heat up to 740°C after stirring, and then use C 2 Cl 6 The refining agent is used for refining treatment for 5-10 minutes. After refining, stir the alloy melt and let it stand at 740°C for 10 minutes. After standing, remove the scum on the surface of the alloy melt to obtain a magnesium alloy melt with good refining effect.

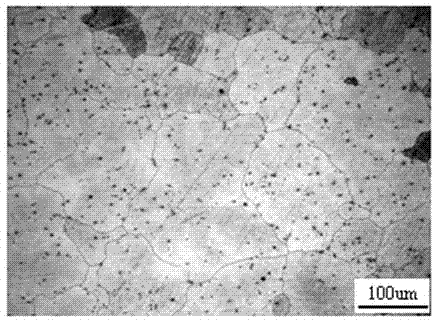

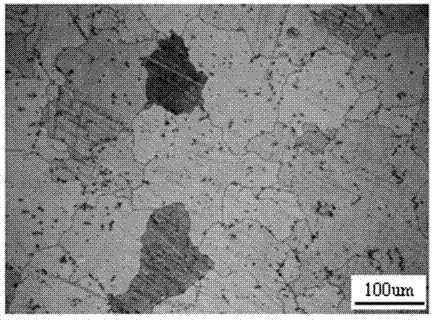

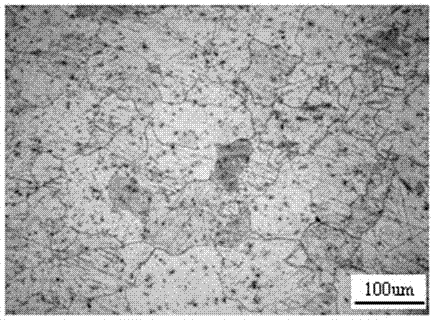

[0028] The grain size test results of the magnesium alloys with Zn-Sr master alloy and no Zn-Sr master alloy used in the three embodiments are shown in Table 1, and the fiber structure pictures are shown in Figure 1A-1E , Figure 2A-Figure 2E , Figure 3A-Figure 2E . From the comparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com