Aluminum silicon lanthanum boron quaternary intermediate alloy and preparing method thereof

A master alloy and aluminum-silicon technology, which is applied in the field of aluminum-silicon-lanthanum-boron quaternary master alloy for casting aluminum-silicon alloy and its preparation field, can solve the problems of inapplicability to mass production, serious burning loss, and low yield of elements. Achieve excellent refinement effect, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

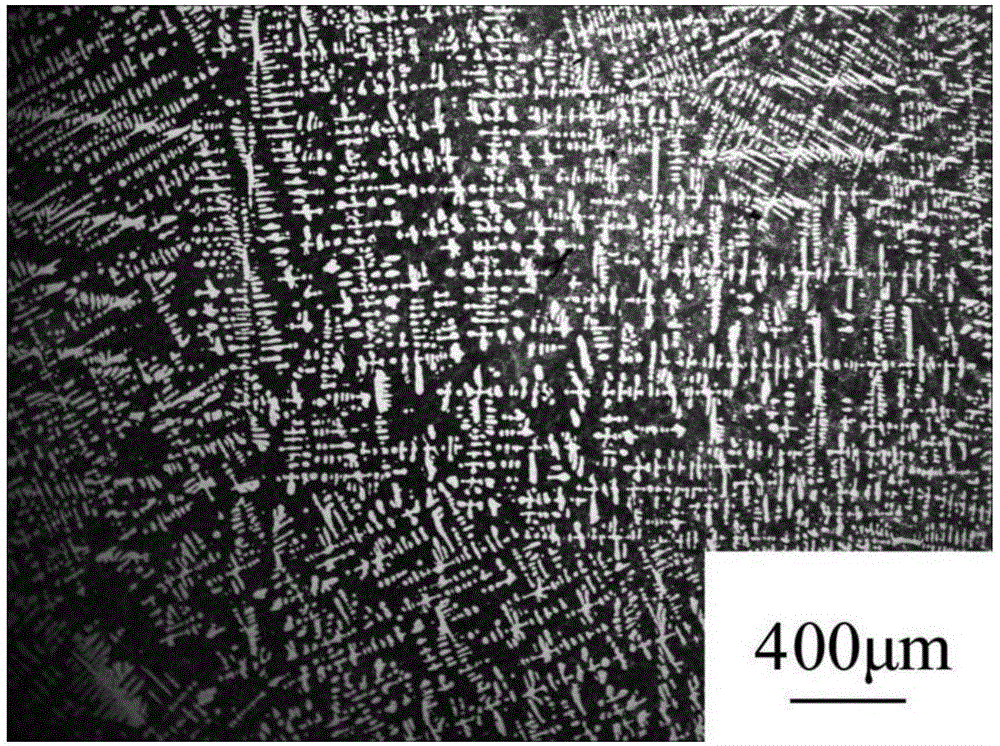

Embodiment 1

[0032] Embodiment 1: The preparation method of Al-Si-La-B master alloy in this embodiment is as follows:

[0033] Step 1: using industrial pure aluminum, crystalline Si, Al-10La master alloy and Al-3B master alloy as raw materials, the mass ratio of the four raw materials is 1:0.2:0.5:0.8, weighed and dried in an oven for later use;

[0034] Step 2: Crush the crystalline silicon into particles with an average size of about 1mm, and evenly spread it on the bottom of the graphite clay crucible;

[0035] Step 3: Place the graphite clay crucible in step 2 in a crucible resistance furnace, place the dried industrially pure aluminum on the crystalline Si particles, melt at 850°C, and keep it warm for 2 hours to obtain a uniform aluminum-silicon melting body.

[0036] Step 4: Add the dried Al-3B master alloy and keep it at 850°C for 20 minutes to obtain a uniform melt.

[0037] Step 5: In the homogeneous melt obtained in step 4, add the Al-10La master alloy at 880°C and keep it war...

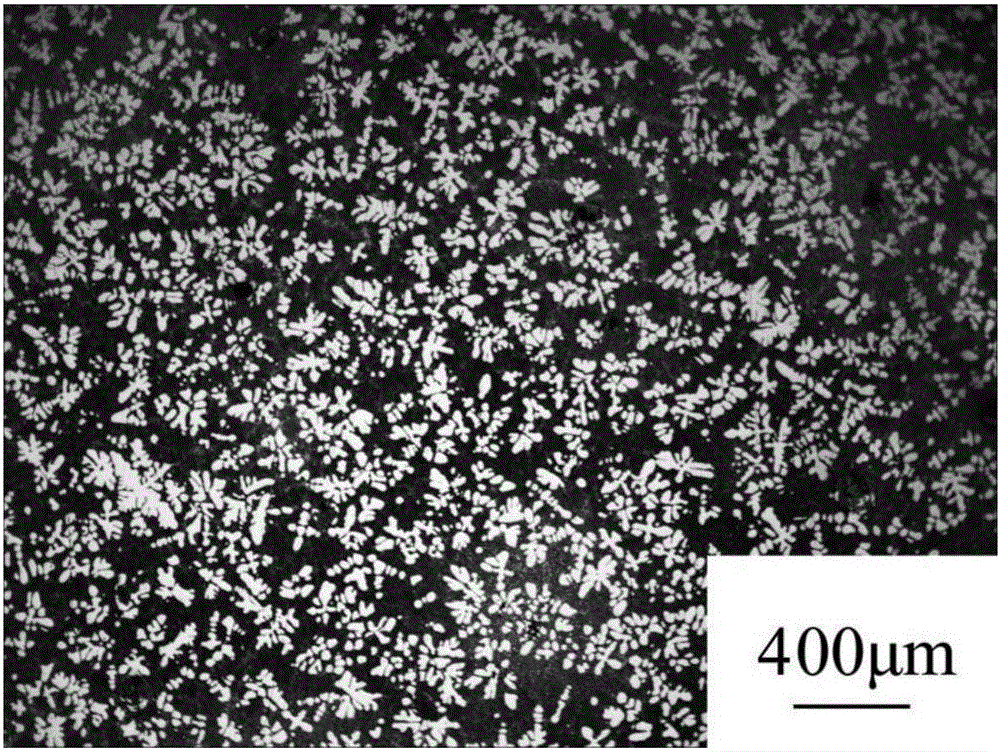

Embodiment 2

[0043] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of the four raw materials in step 1 is 1:0.4:0.8:1.2, and the others are the same as Embodiment 1.

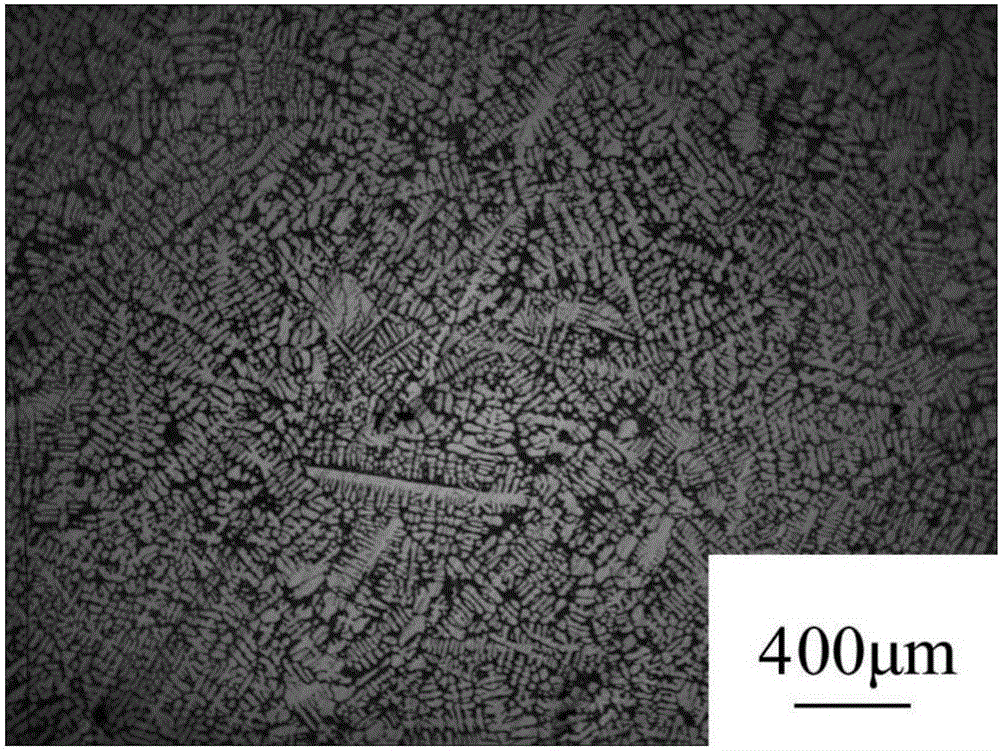

Embodiment 3

[0044] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the mass ratio of the four raw materials in Step 1 is 1:0.3:0.7:1, and the others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com