Circulating refining device used for continuously preparing aluminum alloy semisolid slurry

A technology of semi-solid slurry and aluminum alloy, which is applied in the field of light alloy semi-solid forming, which can solve the problems of restricting technology promotion and application, continuous preparation, storage and transportation of low-cost high-quality slurry, slurry refinement effect and delivery efficiency Unable to guarantee and other problems, to achieve the effect of high refinement efficiency and convenient continuous collection and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

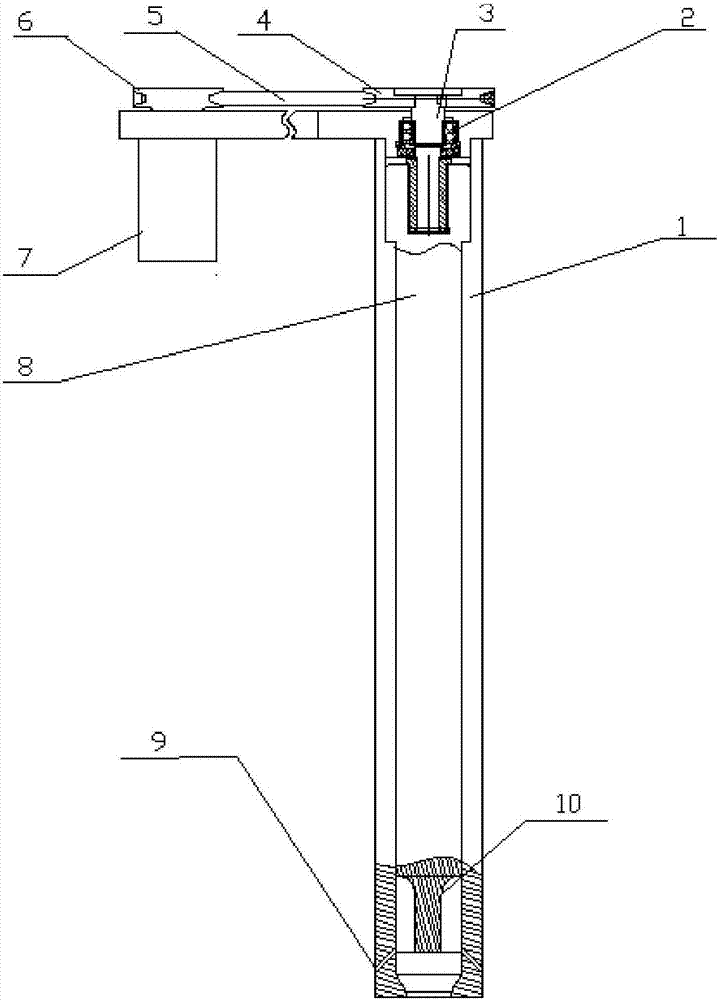

[0014] see figure 1 , is a circulation thinning device for continuously preparing aluminum alloy semi-solid slurry as the best embodiment of the present invention, and is used for refining the slurry, including a driving mechanism and a thinning mechanism, and the thinning mechanism of the thinning mechanism The refining part extends into the crucible where the slurry is placed to refine the slurry. The refining mechanism includes a rotor 8 and a stator 1. The inside of the stator 1 is hollow, and the rotor 8 is placed inside the stator 1. The driving mechanism drives the rotor 8 inside the stator 1. rotate. The thinning part of the stator 1 immersed in the slurry to perform the thinning function is provided with a thinning cavity, the rotor 8 in the thinning cavity is provided with blades 10, and the bottom of the stator 1 is provided with a suction port communicating with the thinning cavity , and a jet hole 9 is opened on the side wall of the stator 1 in the thinning cavit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com