High-strength and high-toughness Al-Cu-(Al-Ti-Nb-B) alloy and preparation method thereof

An al-ti-nb-b, high-strength and high-toughness technology, which is applied in the field of high-strength and high-toughness Al-Cu-alloy and its preparation, can solve the problems of reduced grain refinement efficiency, thermal cracks, and hindering interdendritic liquid phase compensation. Material and other issues, to achieve the effect of improved tensile mechanical properties, obvious tensile mechanical properties, and improved element utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A preparation method of a high-strength and high-toughness Al-5Cu-0.5 (Al-2.5Ti-2.5Nb-0.5B) alloy, which specifically comprises the following steps:

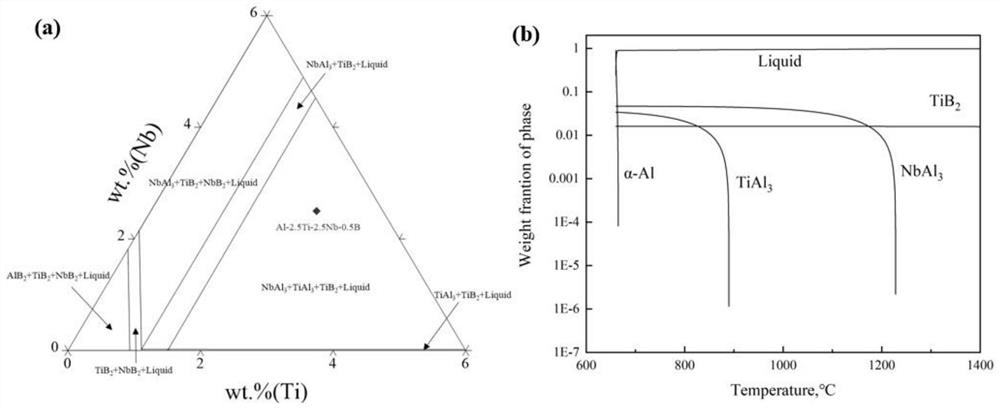

[0074] Step 1, preparation of Al-Ti-Nb-B master alloy, using potassium fluorotitanate as Ti source material, potassium fluoroborate as B source material, Nb 2 O 5 As the Nb source material, the Al-Ti-Nb-B master alloy was prepared by the fluorine salt reaction method. The Al-Ti-Nb-B master alloy was composed of the following mass percentages: 2.5% Ti, 2.5% Nb, 0.5% B, the remainder is Al;

[0075] Step 2, smelting of Al-Cu alloy melt, first, preheat the pit furnace to 400℃ to remove moisture in the furnace, at the same time, preheat pure aluminum at 300℃, and then preheat the preheated The pure aluminum is put into a pit furnace and smelted at 750 °C. After the pure aluminum is completely melted, the surface scum is removed and the scale is removed. The melt temperature is kept at 750 °C, and the mass percentage of Cu c...

Embodiment 2

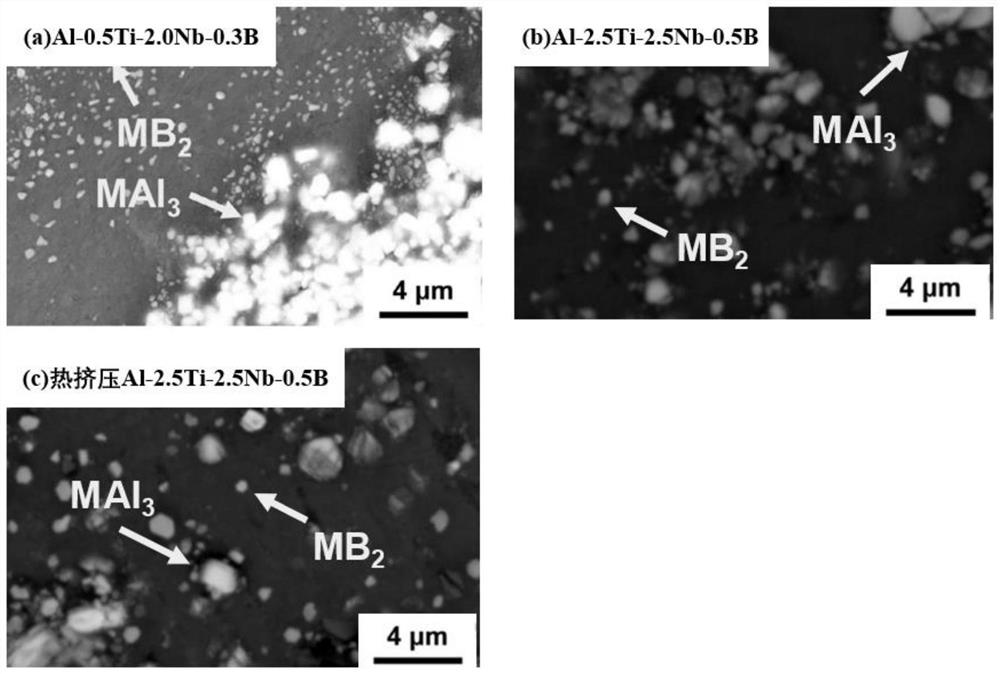

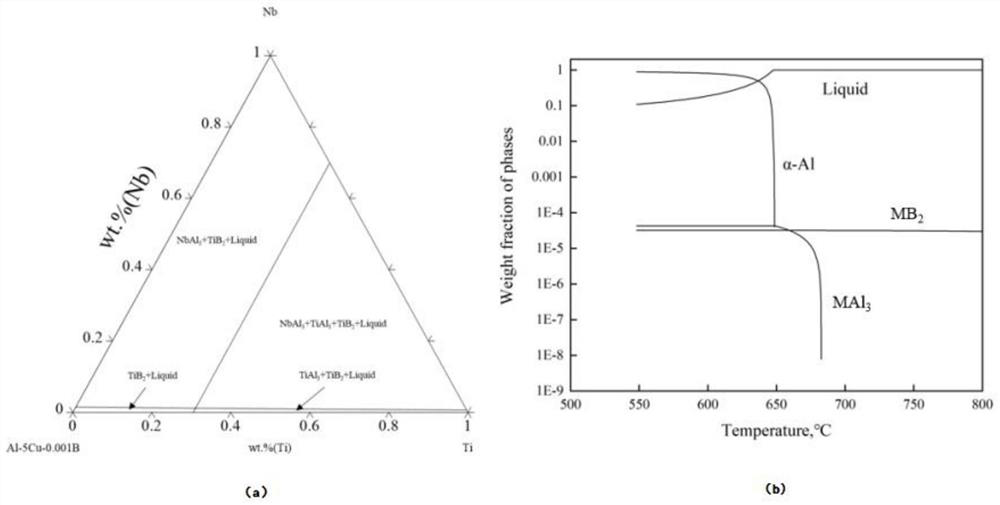

[0100] An Al-5Cu-0.2 (Al-2.5Ti-2.5Nb-0.5B) alloy with an Al-Ti-Nb-B master alloy addition of 0.2%, the unspecified steps are the same as those in Example 1, the difference is In: performing the step 1, adding the following steps, hot extrusion of the Al-2.5Ti-2.5Nb-0.5B alloy ingot, and machining the Al-2.5Ti-2.5Nb-0.5B alloy ingot obtained in the step 1 treated to remove surface burrs and oxide skin, and then placed in a heat treatment furnace with a temperature of 400 °C for 2 h, the extrusion temperature was controlled to be 400 °C, and the extrusion ratio was controlled to be 16; in the step 4, Al-2.5 The addition amount of the Ti-2.5Nb-0.5B alloy rod is 0.2%; the subsequent operation is the same as that in Example 1, and the Al-5Cu-0.2 (Al-2.5Ti-2.5Nb-0.5B) alloy can be obtained.

[0101] In order to obtain the grain size data of Example 2, metallographic observation was carried out. Observations such as Figure 10 As shown in Example 2, the average grain size of the as...

Embodiment 3

[0103] An Al-5Cu-0.5 (Al-2.5Ti-2.5Nb-0.5B) alloy with an Al-Ti-Nb-B master alloy addition amount of 0.5%, the steps not specified are the same as those in Example 1, the difference is In: performing the step 1, adding the following steps, hot extrusion of the Al-2.5Ti-2.5Nb-0.5B alloy ingot, and machining the Al-2.5Ti-2.5Nb-0.5B alloy ingot obtained in the step 1 treated to remove surface burrs and oxide skin, and then placed in a heat treatment furnace with a temperature of 400 °C for 2 h, the extrusion temperature was controlled to be 400 °C, and the extrusion ratio was controlled to be 16; in the step 4, Al-2.5 The addition amount of the Ti-2.5Nb-0.5B alloy rod is 0.5%; the subsequent operation is the same as that in Example 1, and the Al-5Cu-0.5 (Al-2.5Ti-2.5Nb-0.5B) alloy can be obtained.

[0104] In order to obtain the grain size data of Example 3, metallographic observations were performed. Observations such as Figure 10 As shown in Example 3, the average grain size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com