High-efficiency clean Al-Ti-B refiner and preparation method thereof

A technology of al-ti-b and refiner, which is applied in the field of high-efficiency clean refiner and preparation, can solve the problems of low preparation efficiency, low preparation cost, and low refinement efficiency, and achieve improved refinement efficiency, Uniform distribution and small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

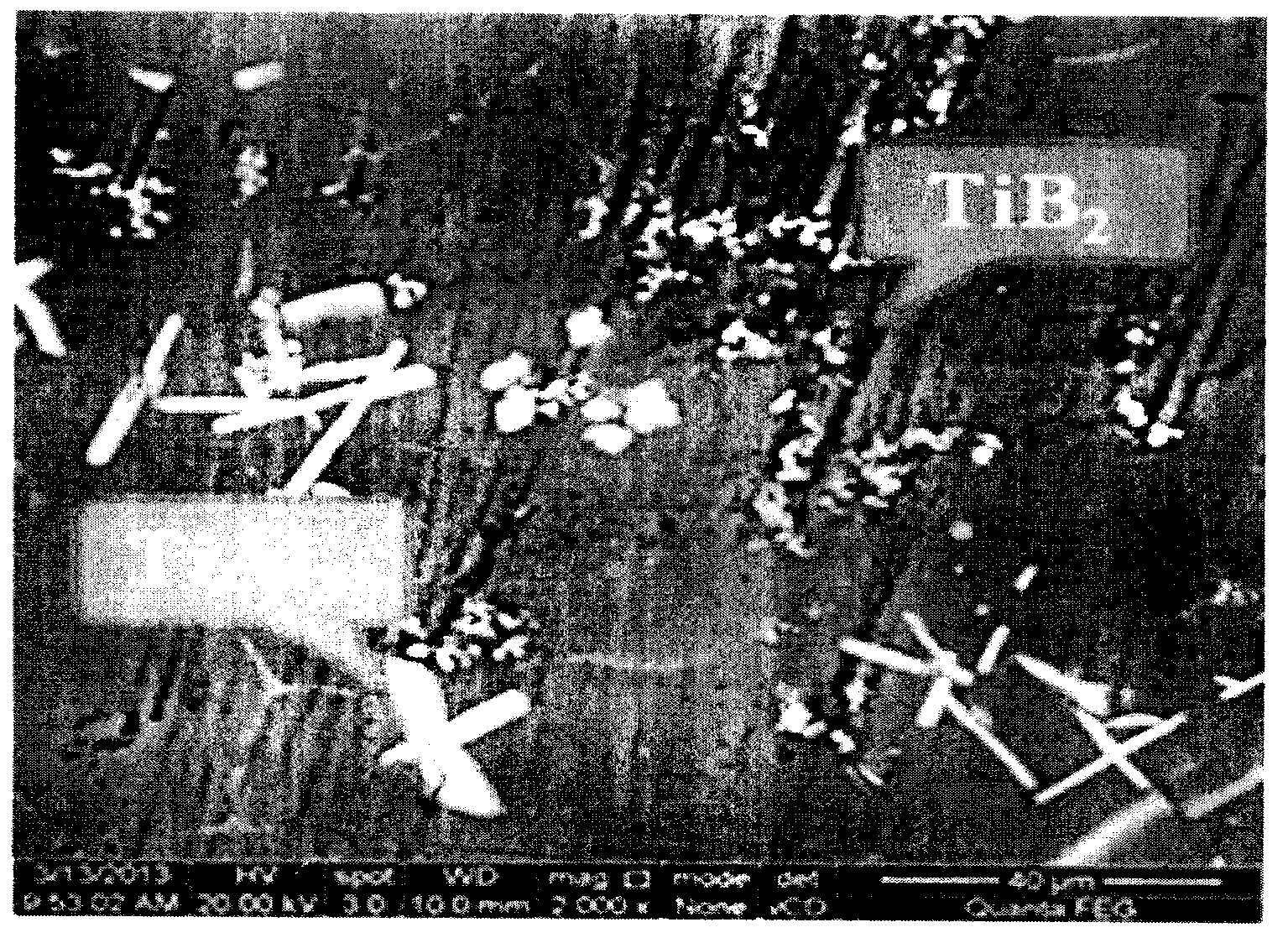

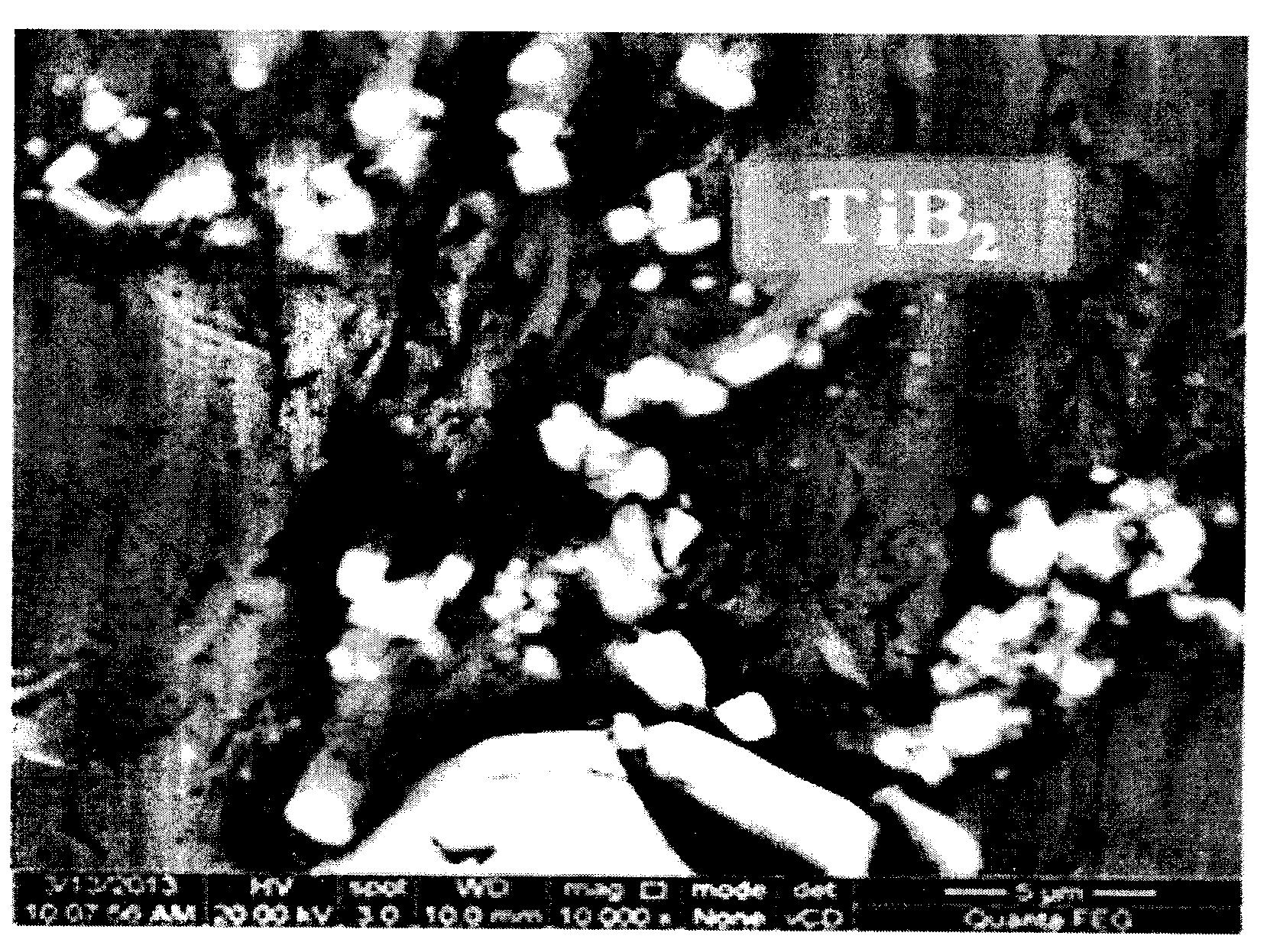

Image

Examples

Embodiment 1

[0018] The process of preparing Al-Ti-B refiner by contact reaction method is as follows:

[0019] 1. Raw material preparation, refiner by B 2 o 3 、TiO 2 , aluminum powder, aluminum ingot, C 2 Cl 6 It is prepared with cryolite covering agent, wherein the purity of aluminum ingot is 99.9%.

[0020] 2. Prepare 1Kg of refiner, weigh B as required 2 o 3 、TiO 2 , aluminum powder, aluminum ingot, according to the aluminum burning rate of 3%, require TiO 2 :B 2 o 3 : Al powder = 3: 4: 5 (mol), the rest is Al

[0021] 3 will be B 2 o 3 、TiO 2 The powder is heated at 300°C for two hours to remove the moisture.

[0022] 4. The heated TiO 2 and B 2 o 3 Mix the mixture with aluminum powder evenly, put the evenly mixed powder in the mold, and press it into 70×Φ80mm 3 cylindrical powder block.

[0023] 5. Apply a layer of paint to tools such as molds and slag scrapers to prevent Fe impurity elements from contaminating the refiner. A graphite crucible is selected for smel...

Embodiment 2

[0026] 1. Raw material preparation, refiner by B 2 o 3 、TiO 2 , aluminum powder, aluminum ingot, C 2 Cl 6 It is prepared with cryolite covering agent, wherein the purity of aluminum ingot is 99.9%.

[0027] 2. Prepare 500g of refiner, weigh B as required 2 o 3 、TiO 2 , aluminum powder, and aluminum ingots, the aluminum loss rate is 3%. Requires TiO 2 :B 2 o 3 :Al powder=1.3:2:2.5 (mol).

[0028] 3. Put B 2 o 3 、TiO 2 The powder is heated at 300°C for two hours to remove the moisture.

[0029] 4. The heated TiO 2 and B 2 o 3 Mix the mixture with aluminum powder evenly, put the evenly mixed powder in the mold, and press it into 90×Φ80mm 3 cylindrical powder block.

[0030] 5. Use a well-type resistance furnace to heat the cleaned aluminum ingot to 780°C. After the aluminum ingot is completely melted, cover it with a layer of cryolite to prevent the oxidation and gas absorption of aluminum; raise the furnace temperature to 950°C, and the graphite bell jar will ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com