Magnesium base composite hydrogen storage material and preparation method

A technology of hydrogen storage materials and ball-to-material ratio, which is applied in the field of magnesium-based composite hydrogen storage materials and its preparation, can solve the problems of poor kinetic performance of hydrogen absorption and desorption reactions, and no hydrogen storage material system has been reported, so as to facilitate purification and storage Transport, promote the hydrogen absorption and desorption reaction, the effect of low hydrogen absorption and desorption temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

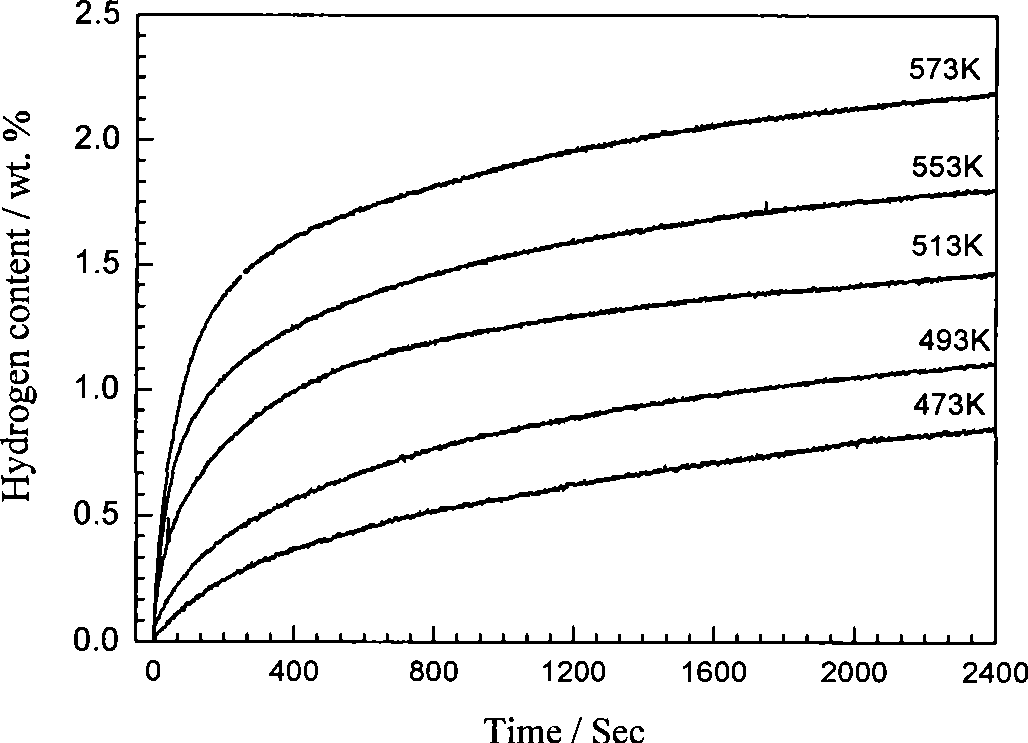

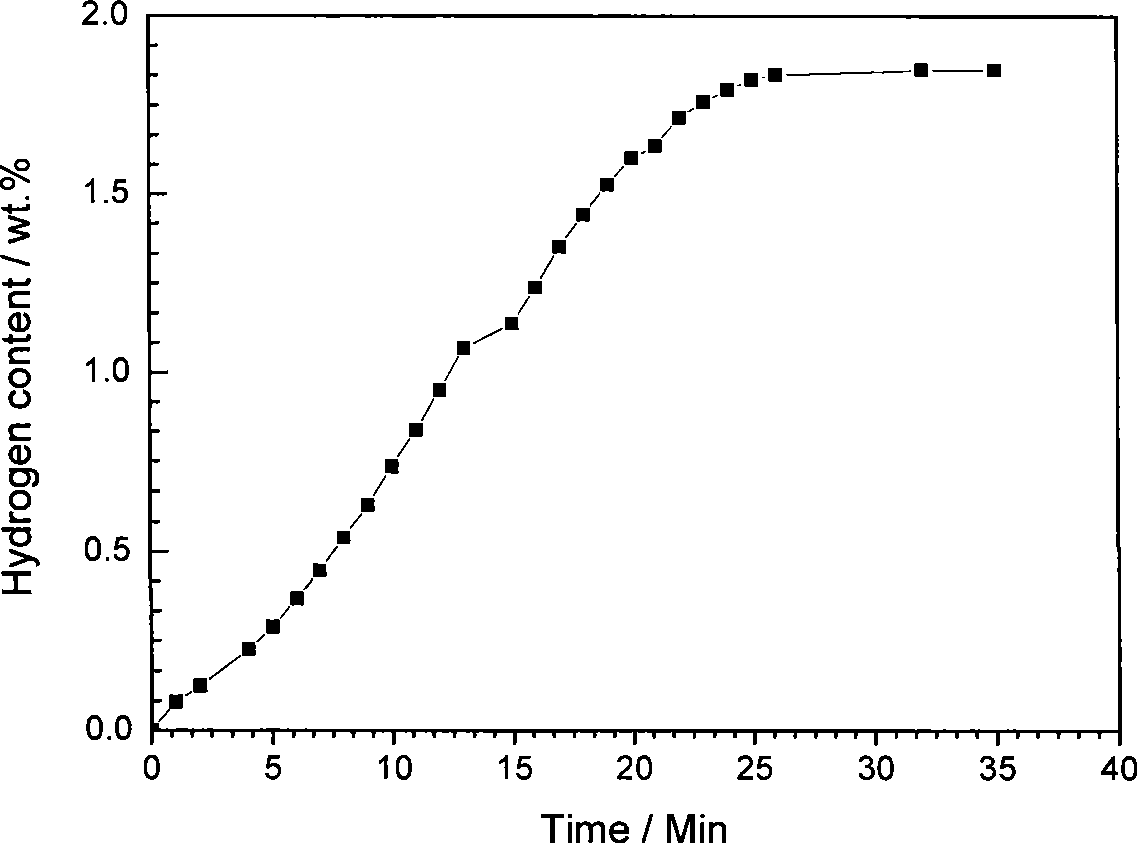

[0016] The bulk metal Mg and Al are mixed according to the atomic ratio of 17:12, and Mg is prepared by intermediate frequency induction melting under vacuum conditions. 17 Al 12 Alloys are mechanically crushed to 300 mesh. Nanocrystalline Mg was obtained by ball milling for 80 hours under the protective atmosphere of argon 17 Al 12 Alloy powder. At 200℃ and 4.0MPa hydrogen pressure, the alloy can absorb hydrogen without any activation treatment, and the hydrogen absorption speed increases with the increase of temperature. Nanocrystalline Mg 17 Al 12 The hydrogen absorption curve of the alloy is as figure 1 As shown, nanocrystalline Mg 17 Al 12 The hydrogen desorption curve of the alloy is as figure 2 shown. It can be seen from the figure that the nanocrystalline Mg after ball milling 17 Al 12 The alloy has certain reversible hydrogen absorption and desorption properties, and has hydrogen absorption and desorption activity, which is beneficial to promote the hydro...

Embodiment 2

[0018] Preparation of Mg by Intermediate Frequency Induction Melting of Bulk Metal Mg and Al under Vacuum Condition 17 Al 12 Alloys are mechanically crushed to 300 mesh. Mg powder (200 mesh) was hydrogenated at 340°C under a hydrogen atmosphere (hydrogen pressure 4.0MPa) to prepare MgH 2 . Mg 17 Al 12 , MgH 2 , Ni (300 mesh) are mixed according to the weight percentage content of 3.54% Al, 5.0% Ni, and the remaining Mg. The Mg-Al-Ni composite hydrogen storage material was obtained by ball milling for 80 hours under an argon atmosphere. The hydrogen storage material can undergo a hydrogen absorption reaction at 120°C, and the hydrogen absorption amount can reach 5.6wt.% within 30 minutes at 160°C, and more than 6.0% at 180°C. Under the conditions of 260°C and 1 atmospheric pressure, the amount of hydrogen released reaches 5.0wt.% in 80 minutes.

Embodiment 3

[0020] Preparation of Mg by Intermediate Frequency Induction Melting of Bulk Metal Mg and Al under Vacuum Condition 17 Al 12 Alloys are mechanically crushed to 300 mesh. Mg powder (200 mesh) was hydrogenated at 340°C under a hydrogen atmosphere (hydrogen pressure 4.0MPa) to prepare MgH 2 . Mg 17 Al 12 , MgH 2 , Ni (300 mesh) are mixed according to the weight percentage content of 9.5% Al, 1.0% Ni, and the remaining Mg. The Mg-Al-Ni composite hydrogen storage material was obtained by ball milling for 80 hours under an argon atmosphere. The hydrogen storage material can undergo a hydrogen absorption reaction at 120°C, and the hydrogen absorption amount can reach 5.05wt.% within 30 minutes at 160°C, and 5.82% at 180°C. Under the conditions of 260°C and 1 atmospheric pressure, the amount of hydrogen released reaches 4.85wt.% in 80 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com