Dual-driving grinding machine

A grinding machine and double-drive technology are applied in the direction of grinding frame, grinding driving device, and machine tools suitable for grinding workpiece planes, etc., which can solve the inconvenience of increasing the grinding force of the first grinding head and the second grinding head, It is inconvenient to grind the grinding parts, increase the production cost and other problems, and achieve the effect of simple structure, convenient grinding operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

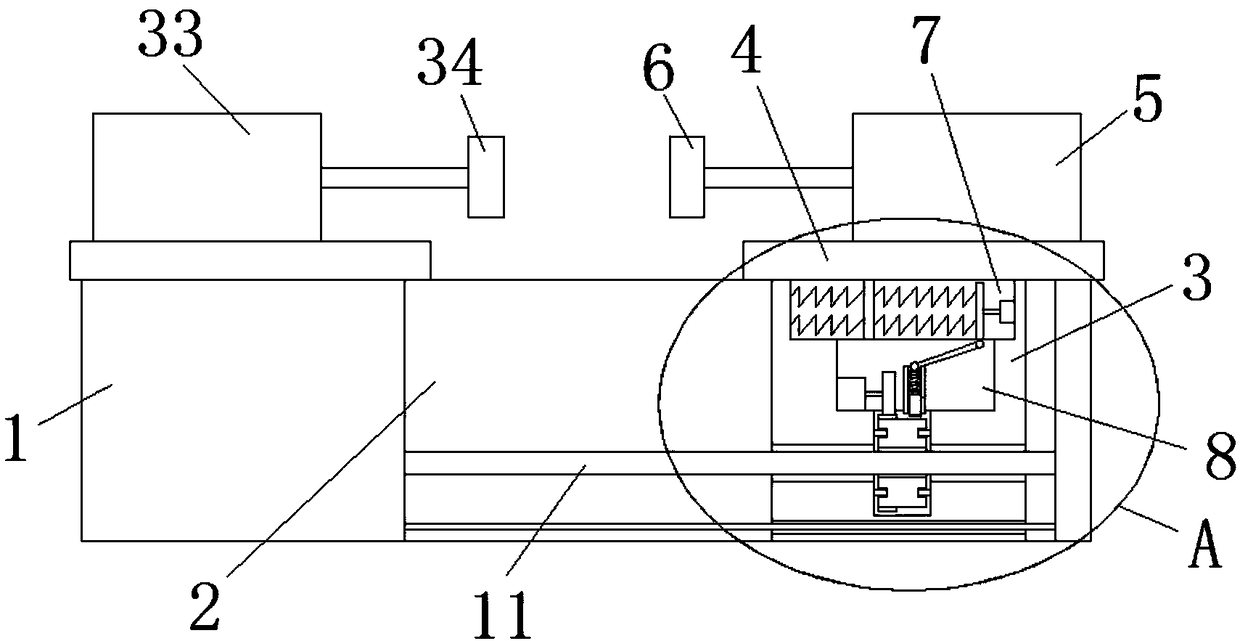

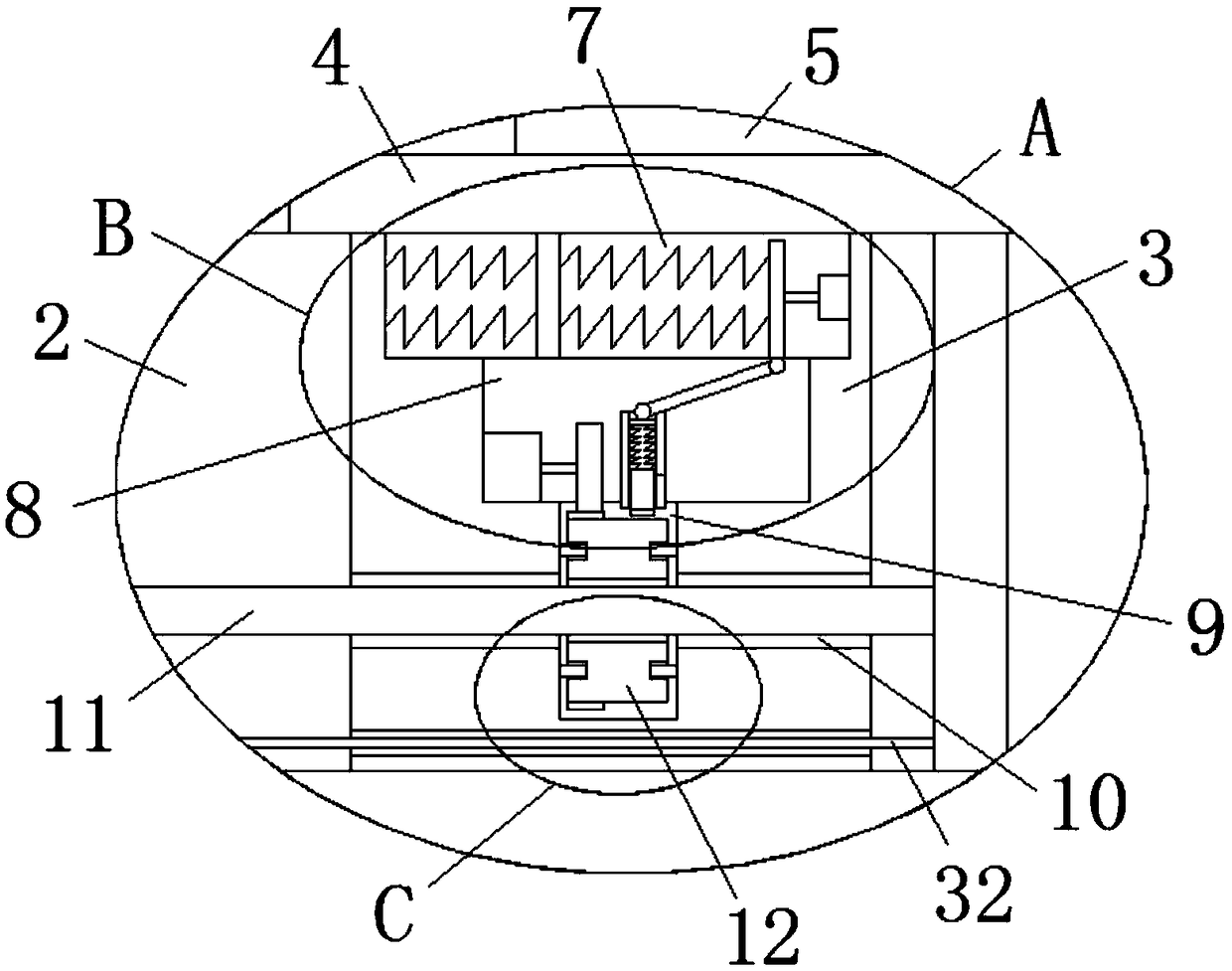

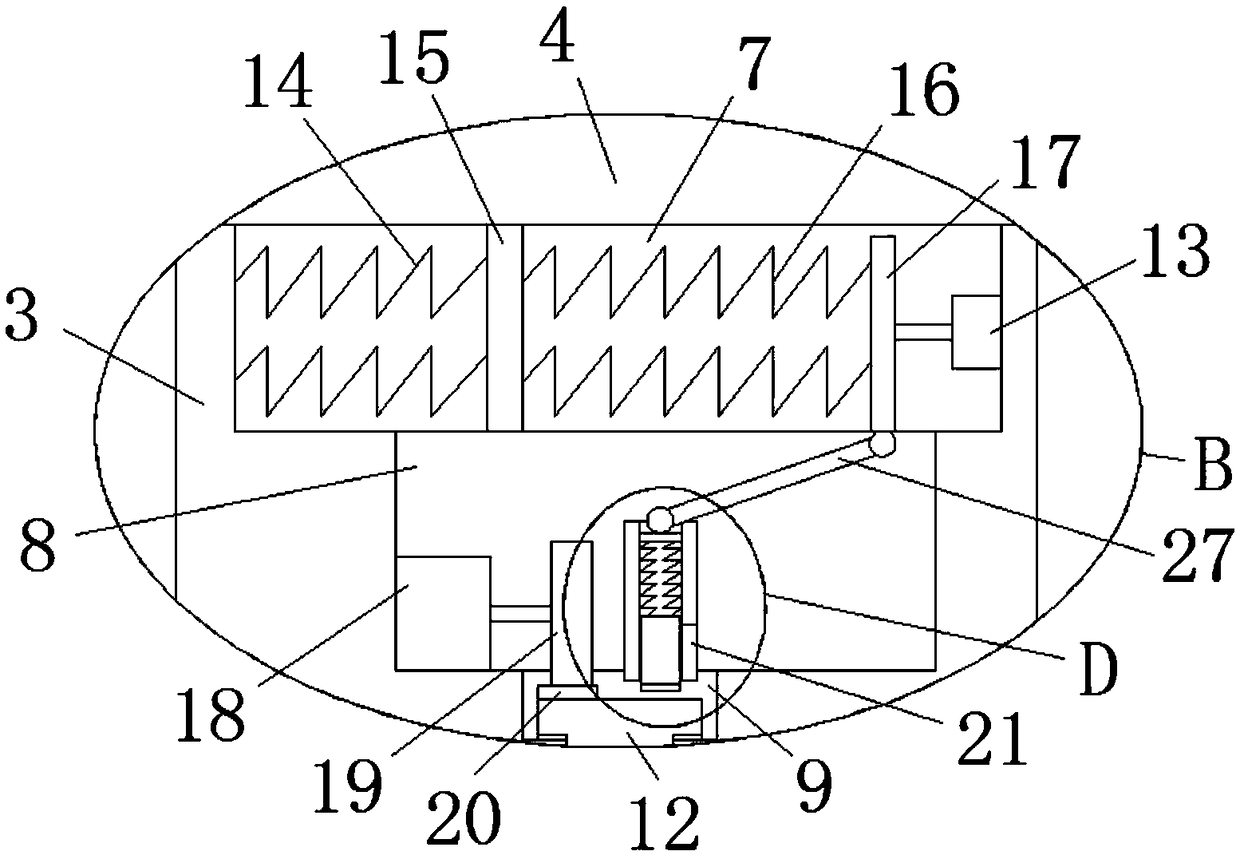

[0027] refer to Figure 1-5In this embodiment, a grinding machine with double drives is proposed, which includes a workbench 1, on which a slide hole 2 is opened, a slide plate 3 is slidably installed in the slide hole 2, and a second slide is installed on the top of the workbench 1. A plate 4, a first motor 5 is fixedly installed on the top of the first plate 4, a first grinding head 6 is fixedly installed on the output shaft of the first motor 5, a first groove 7 is provided on the top of the slide plate 3, and the first groove 7 The second groove 8 on the bottom inner wall of the second groove 8 is provided with a rotating groove 9 on the bottom inner wall of the second groove 8, and a through hole 10 is provided on the inner wall of both sides of the rotating groove 9, and the same screw rod is arranged in the two through holes 10. 11. The two ends of the screw rod 11 are respectively welded to the inner walls of both sides of the sliding hole 2. The screw rod 11 is thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com