Tungsten-rhenium solid alloy powder with nanocrystalline structure as well as preparation method and application of tungsten-rhenium solid alloy powder

A technology of alloy powder and nanocrystal, which is applied in the field of tungsten-rhenium solid alloy powder with nanocrystal structure and its preparation, can solve the problems affecting the performance of alloy powder, high powder activity, powder agglomeration, etc., and achieve improved grinding strength and density , the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

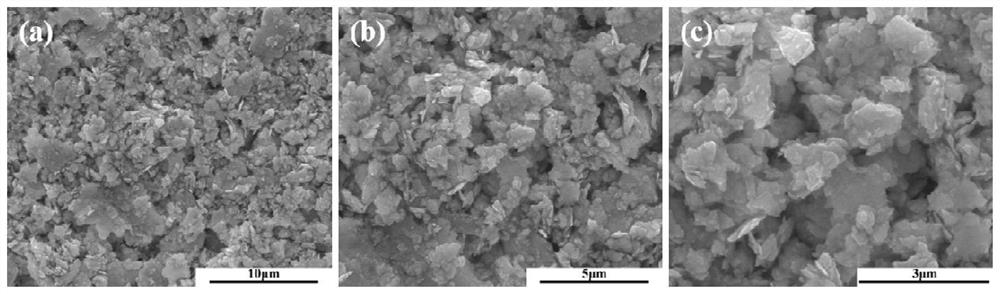

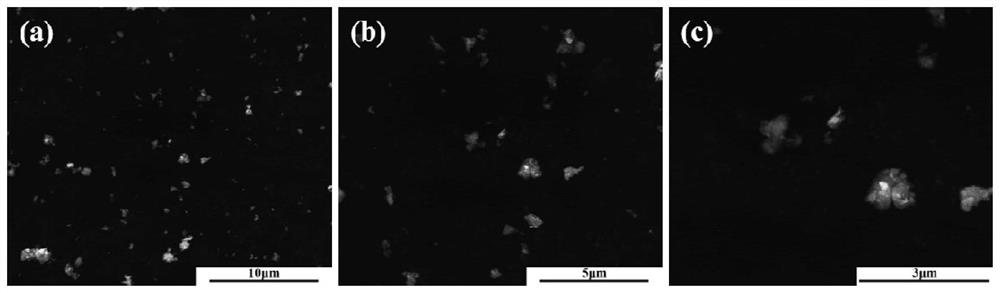

[0056] A method for preparing low-agglomeration high-activity low-oxygen-content tungsten-rhenium solid-state alloy powder with nanocrystalline structure, comprising the following steps:

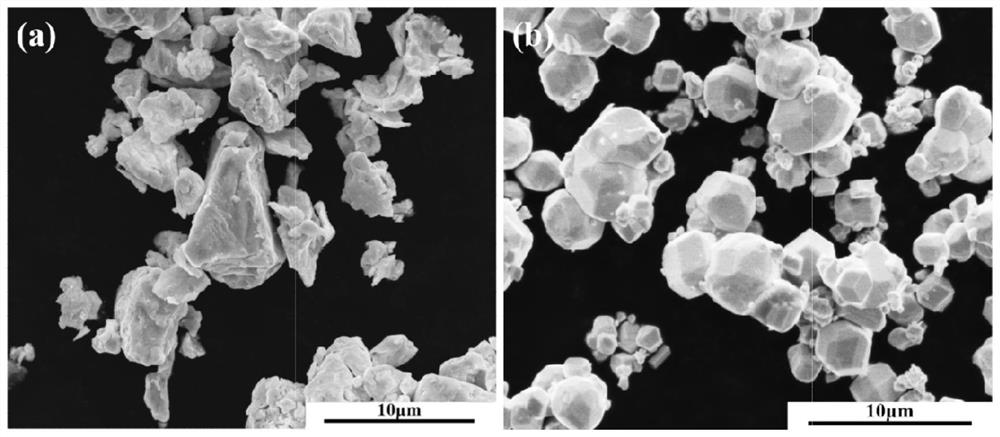

[0057] Step 1: Solid-state alloying of tungsten-rhenium powder by high-energy ball milling

[0058] Take 170g of tungsten powder with a purity of more than 99.95%; 30g of rhenium powder, the average particle size of tungsten powder is 3-5 microns, and the average particle size of rhenium powder is 5 microns; the mass ratio of tungsten powder:rhenium powder is 85:15. The prepared raw material powder is placed in the ball mill tank, the ball mill beads are cemented carbide beads, and the mass is 2000g; the ball mill medium is anhydrous ethanol, and the addition amount of anhydrous ethanol is 1 / 2 of the volume of the ball mill tank; the ball mill tank used It is a cemented carbide ball mill jar, the model is YN8, the volume is 1L, the inner layer of the tank is WC layer, and the hardness is 89H...

Embodiment 2

[0066] A method for preparing a low-aggregation, high-activity, low-oxygen-content tungsten-rhenium solid-state alloy powder with nanocrystalline structure. Other conditions are the same as in Example 1, except that the mass ratio of tungsten powder to rhenium powder is changed. The mass ratios of tungsten powder:rhenium powder are 1:99, 5:95 and 10:90 respectively.

[0067] The prepared powder was tested by X-ray automatic diffractometer (XRD, Advance D8). Figure 5 As shown, the tungsten-rhenium solid-state alloying powder prepared by this method can achieve complete solid-state alloying when the rhenium content is within 15 wt.%, and no peak of Re is observed in the XRD detection result. At the same time, no oxide peak was observed in the detection result, which proved that the powder was not oxidized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com