Household single-motor processor for rotating food waste forwardly and reversely and crushing food waste

A food waste treatment, forward and reverse technology, used in indoor sanitary pipe installations, water supply installations, buildings, etc., can solve problems such as large residues, complex structures, machine stuck, etc., to improve the crushing effect and crushing efficiency, The effect of improving the crushing effect and changing the processing direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

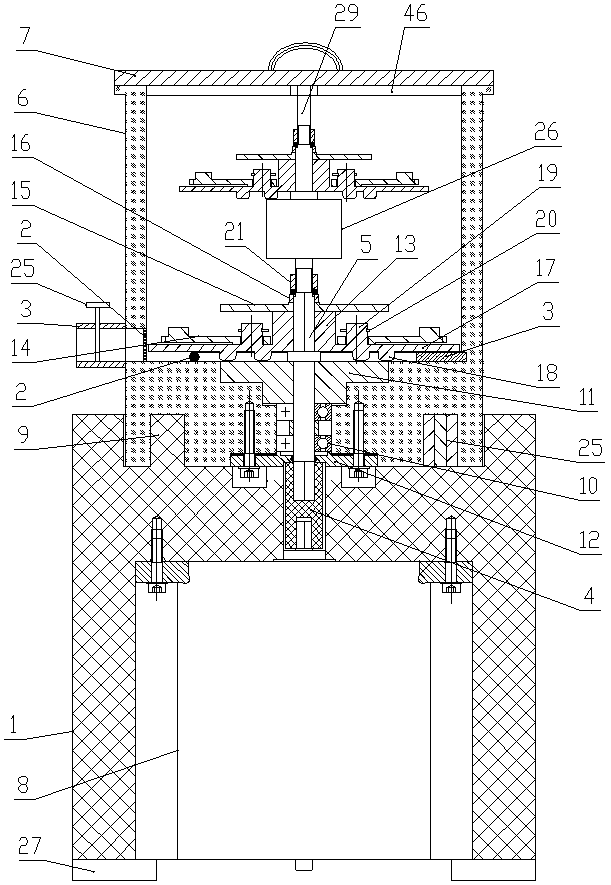

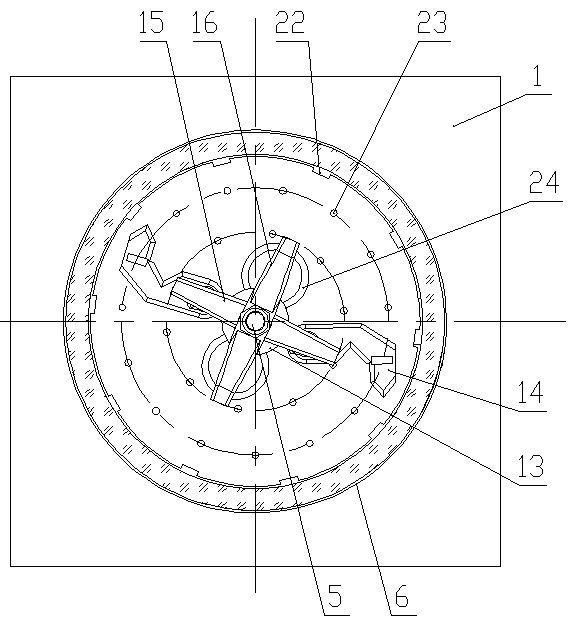

[0033] Such as Figure 1-Figure 7 As shown, the household single motor of the present invention realizes forward and reverse rotation and crushing food waste disposer, including a base 1, a rotating shaft 5, a cup body 6, a motor 8, an upper cutter crushing assembly and a lower cutter crushing assembly, and the top of the base 1 is set There is a circular placement slot, the bottom of the base 1 is provided with a cylindrical installation slot with an open bottom, the motor 8 is arranged in the installation slot and the main shaft of the motor 8 is arranged vertically upward, and a positioning column 9 is arranged in the placement slot along the vertical direction , the cup body 6 is provided with a positioning groove corresponding to the positioning column 9, the bottom of the cup body 6 is arranged in the placement groove and the positioning column 9 is inserted into the positioning groove correspondingly, and the top of the cup body 6 is provided with a cup cover 7;

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com