Raw material crushing device for intelligent automobile manufacturing

A technology of intelligent manufacturing and raw material crushing, which is applied in the direction of grain processing, etc., can solve the problems of low intelligence, inability to meet the needs of production and use, and poor crushing effect, so as to improve the crushing effect, improve the crushing effect and crushing efficiency, and improve the filtering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

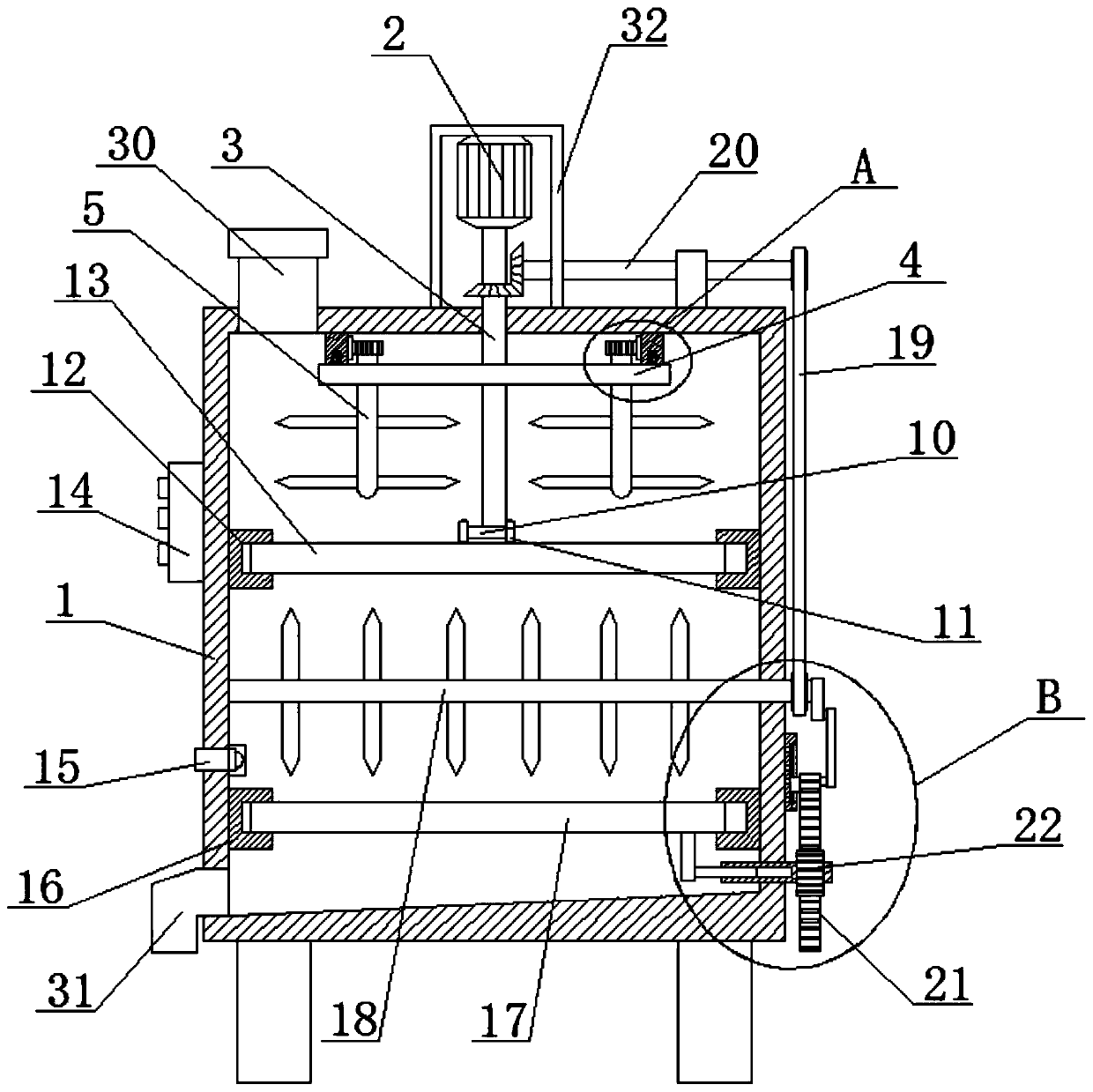

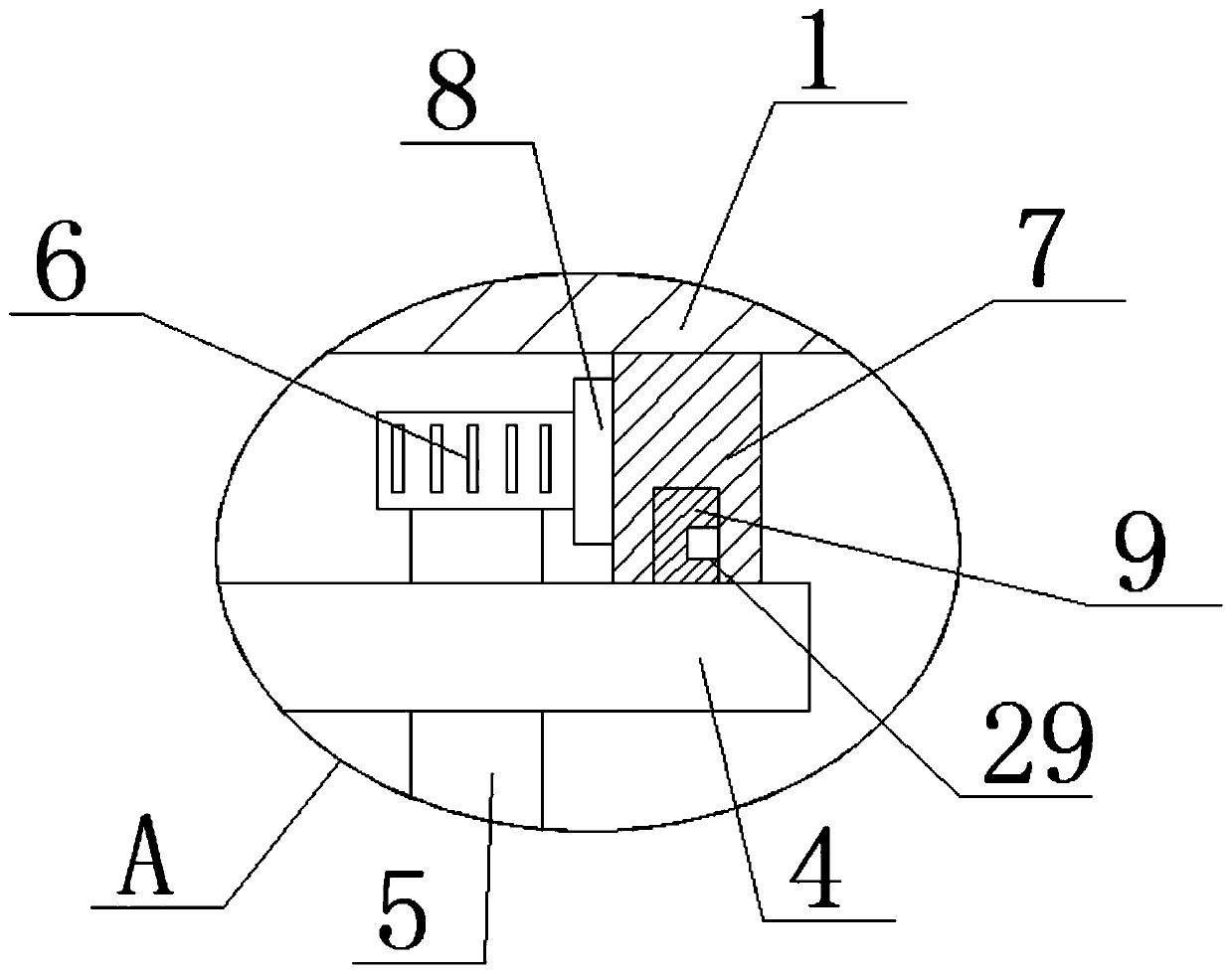

[0036] see Figure 1-6, the present embodiment provides a raw material crushing device for intelligent automobile manufacturing, including a crushing box 1, a feeding port 30 is provided on the top of the crushing box 1, a discharge pipe 31 is provided on one side of the crushing box 1, and the crushing box 1 Rotating shaft 3 is installed at the center of the top of the crushing box 1. A protective shell 32 is fixedly installed on the top of the crushing box 1. A rotating motor 2 is fixedly installed on the inner wall of the top of the protective shell 32. The output shaft of the rotating motor 2 is fixed to the top of the rotating shaft 3. Installation, crushing box 1 is provided with a primary filter 13 and a secondary filter 17, the top of the crushing box 1 is fixedly installed with an annular support block 7, the bottom of the annular support block 7 is provided with an annular groove, and two ring-shaped grooves are slidingly installed in the annular groove One arc-shape...

Embodiment 2

[0042] see Figure 1-6 , made further improvements on the basis of Embodiment 1: two primary guide blocks 12 are fixedly installed on the inner wall of the crushing box 1, and the sides of the two primary guide blocks 12 close to each other are provided with primary guide grooves, and the primary filter screen 13 is slidingly connected with two primary guide grooves, the primary guide block 12 plays a role of supporting and guiding the primary filter screen 13, the top of the primary filter screen 13 is rotatably installed with two thrust rods 11, and the bottom end of the rotating shaft 3 is fixedly equipped with an ellipse The plate 10, the two thrust rods 11 are mutually extruded with the elliptical plate 10, the elliptical plate 10 can drive the primary filter screen 13 to vibrate back and forth by squeezing the two thrust rods 11, and a rack 21 is slidingly installed on one side of the crushing box 1, One end of the secondary crushing shaft 18 is fixedly equipped with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com