Chitin raw material pulverizing device

A raw material crushing and chitin technology, which is applied in solid separation, sieve, grid, etc., can solve the problems of low efficiency, achieve high efficiency, reduce the frequency of cleaning the screen, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

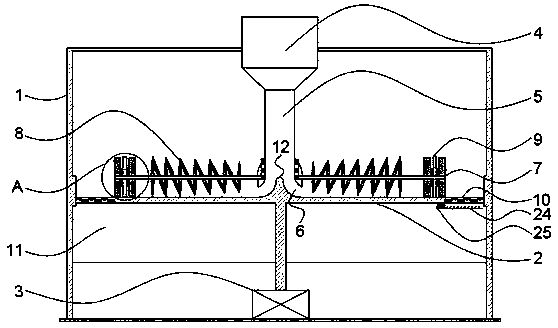

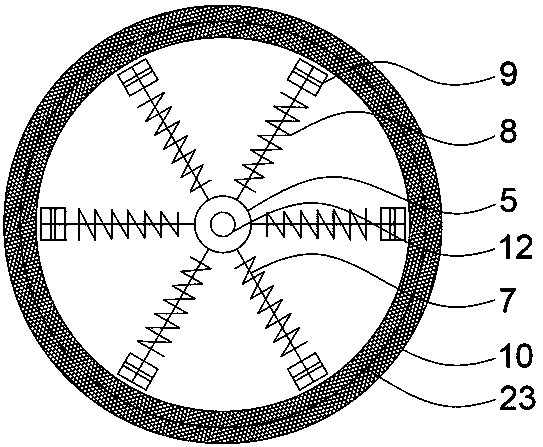

[0025] Such as Figure 1-7Shown, a kind of chitin raw material crushing device comprises frame 1, and frame 1 is rotatably connected with turntable 2, and frame 1 is vertically fixedly connected with feeding pipe 5 above rotating disk 2, and this feeding pipe 5 is connected with The turntable 2 is arranged concentrically, and a discharge port 6 is formed between the lower end of the feeding pipe 5 and the turntable 2. The cutting pipe 5 is connected with some cutter shafts 7, and the length direction of the several cutter shafts 7 is in line with the diameter of the turntable 2. In the same direction, several disc-shaped cutting knives 8 are rotated on the knife shaft 7, and the lower edges of the several cutting knives 8 abut against the upper side of the turntable 2, and the knife shaft 7 is also fixedly connected with a grinding head 9. , the grinding head 9 is located on the outside of the cutting knife 8, the grinding head 9 includes a fixed sleeve, a grinding knife 14 an...

Embodiment 2

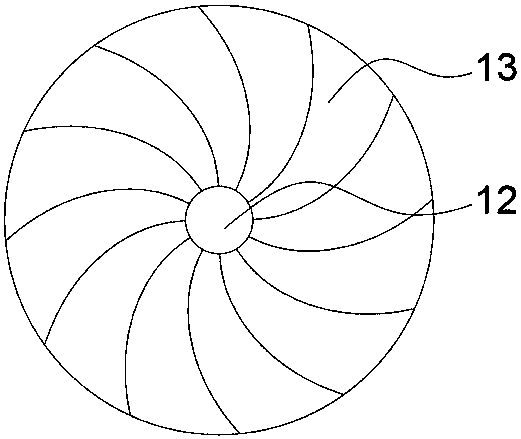

[0027] Such as Figure 1-7 As shown, a chitin raw material crushing device includes a frame 1, a turntable 2 is connected to the inside of the frame 1 for rotation, the turntable 2 is driven by a motor 3, a hopper 4 is fixedly arranged on the frame 1, and a lower part is fixedly connected to the bottom of the hopper 4. Feeding pipe 5, the feeding pipe 5 is perpendicular to the turntable 2 and is coaxially arranged with the turntable 2, and a feeding port 6 is formed between the lower end of the feeding pipe 5 and the turntable 2; the lower end of the feeding pipe 5 is an open end, and the turntable 2 An anti-blocking column 12 is arranged on the position corresponding to the feeding pipe 5. The anti-blocking column 12 is designed in the shape of a truncated cone, and the top of the column is hemispherical. The orientation of the lower chute 13 is the same as the rotation direction of the turntable 2, and the joint position of the anti-blocking column 12 and the turntable 2 is ...

Embodiment 3

[0034] Such as Figure 1-7 As shown, a chitin raw material crushing device, the starting device starts to work, the motor 3 drives the turntable 2 to rotate, the cutter 8, the grinding head 14, and the screen brush 24 start to rotate, and the screen 10 starts to vibrate up and down. Put the chitin raw material in the hopper 4, the raw material moves to the turntable 2 through the feed port 6, and is cut and pulverized by the cutter 8 on the turntable 2, and the action of the spiral cutter 8 and the turntable 2 is controlled by the central position of the turntable 2. Moving to the area of the grinding head 9 at the end of the cutter shaft 7, the area of the grinding head 9 is simultaneously subjected to the cutting action of the grinding knife 14 and the reverse grinding action of the grinding knife 14 and the grinding disc 15, and the material is further pulverized into The finer particles move to the sieve 10 under the impetus of the follow-up particles, pass through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com