Stirring type ball mill

A stirring ball mill and stirring shaft technology, applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of not being good enough, affecting work efficiency, insufficient cleaning, etc., to achieve effective cleaning, prevent blockage of the sieve plate, and achieve the effect of crushing and grinding Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

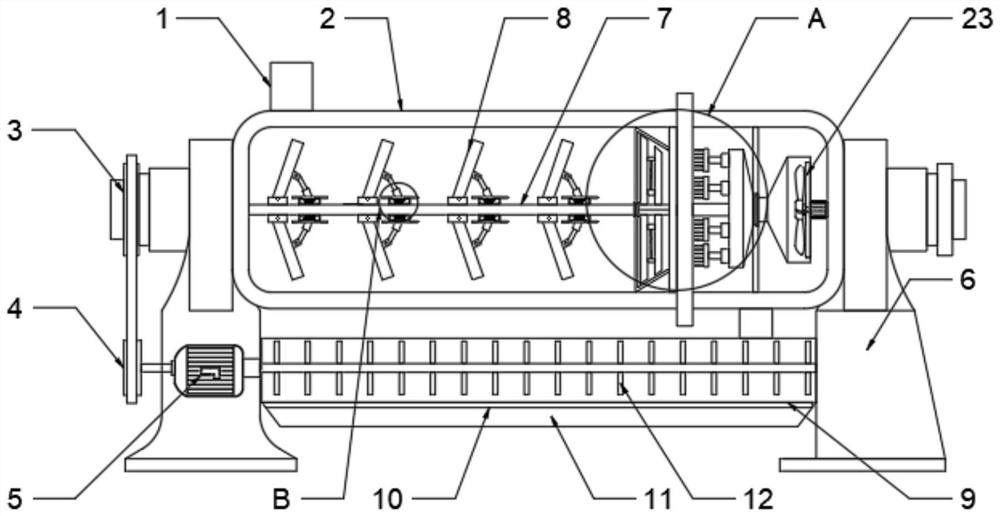

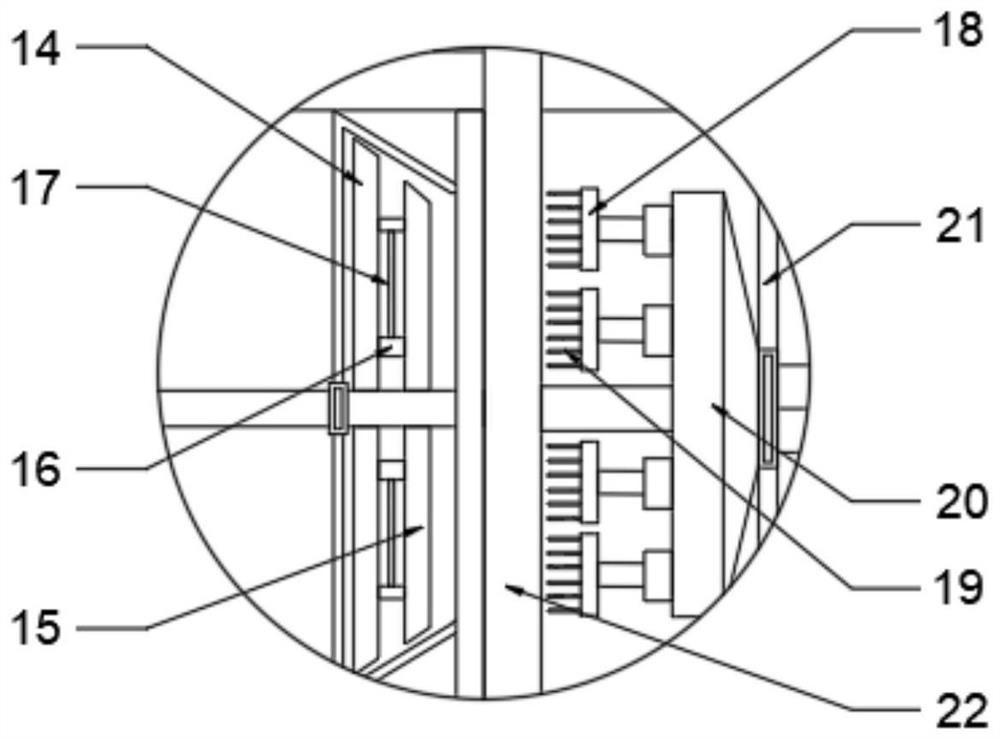

[0023] see Figure 1~4 , in the embodiment of the present invention, a stirring ball mill includes a stirring sleeve 2; the stirring sleeve 2 is fixedly installed on the installation platform 6; the installation platform 6 is provided with two; the inside of the stirring sleeve 2 A primary crushing mechanism is provided; the inside of the stirring sleeve 2 is provided with a dust removal mechanism corresponding to the primary crushing mechanism; the top of the stirring sleeve 2 is provided with a feed port 1; the bottom of the stirring sleeve 2 is connected to two The secondary crushing box 9; the inside of the secondary crushing box 9 is provided with a secondary pulverizer; the corresponding primary pulverizing mechanism and the secondary pulverizer 12 are provided with a drive mechanism on the mounting table 6; the bottom of the secondary pulverizing box 9 A discharge box 11 is provided.

[0024] Further, the drive mechanism includes a servo drive motor 5; the servo drive ...

Embodiment 2

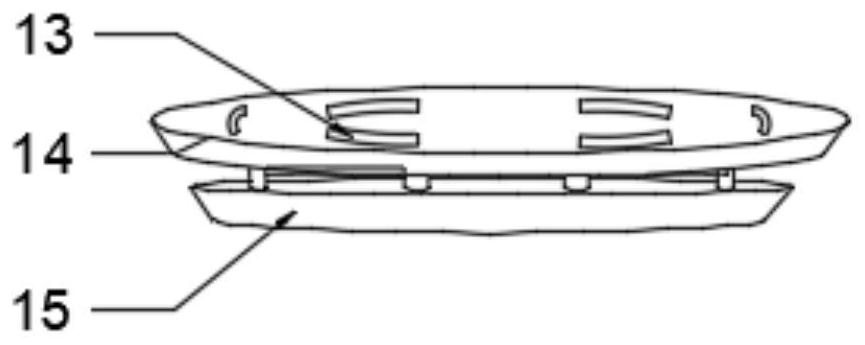

[0030] see Figure 5 , the secondary pulverizer 12 includes a connecting rotating shaft; a plurality of secondary distributing discs are evenly spaced on the connecting rotating shaft; several elliptical through holes are evenly arranged on the secondary powder disc; There are at least ten through holes evenly; the distance between the top of the distribution tray and the inner top of the No. 1 sieve plate 10 is less than the distance of the short axis of the ellipse through hole; The distance of the inner bottom is less than the distance of the minor axis of the ellipse through hole; the inner wall of the No. 1 sieve plate 10 is provided with irregular protrusions; through the setting of the secondary pulverizer 12, the ellipse through hole and the distribution tray, the The material is further pulverized; through the setting of the distance between the distribution tray and the inner wall of the No. 1 sieve plate 10, the material can also vibrate the No. 1 sieve plate 10 whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com