Ball type vertical efficient multistage grinding device

A grinding device and ball-type technology, which is applied in grain processing and other directions, can solve the problems of uneven density distribution of grinding media, affect grinding effect, and difficult grinding, and achieve the effect of good crushing and grinding effect, convenient grinding operation and uniform material particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

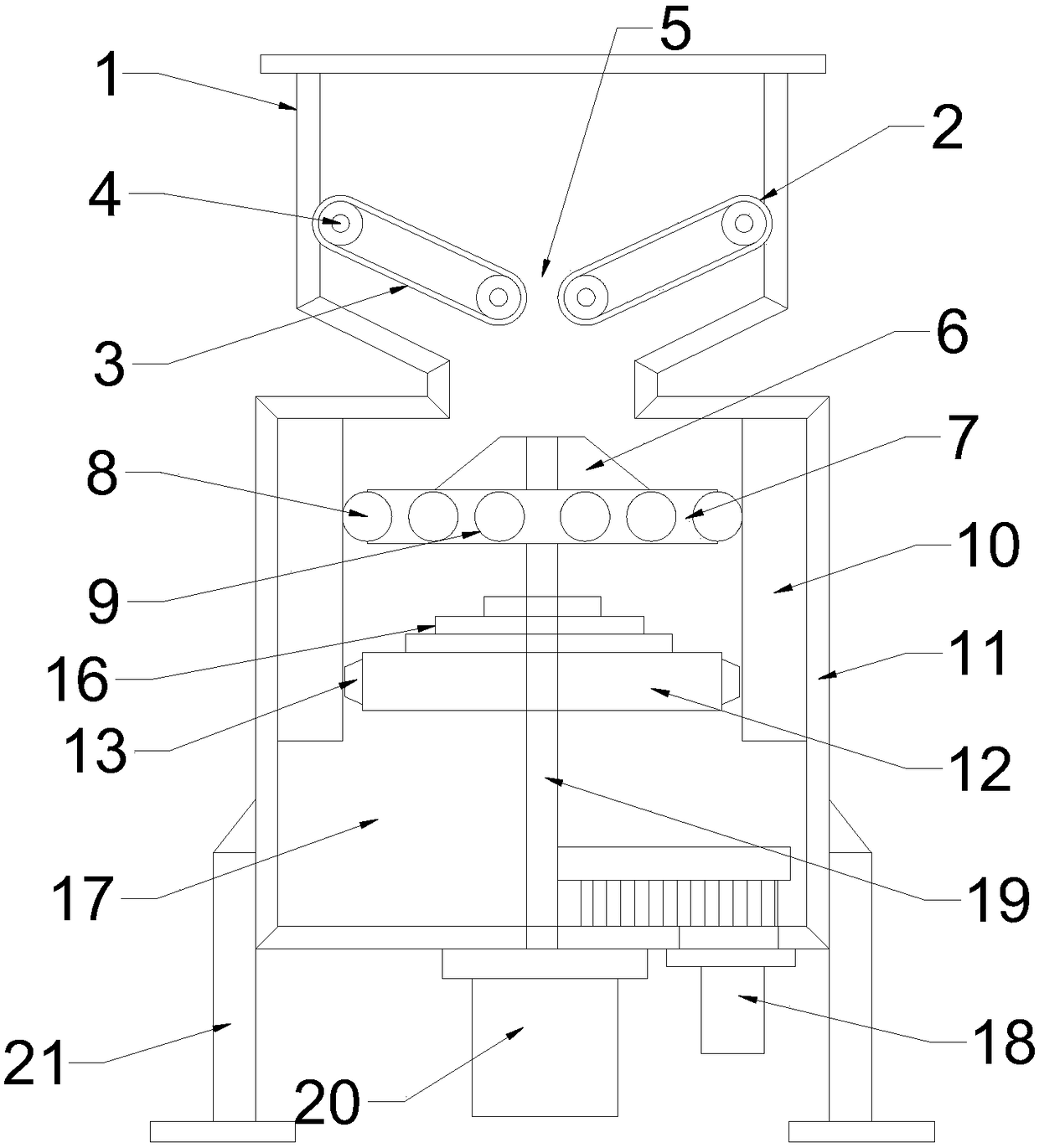

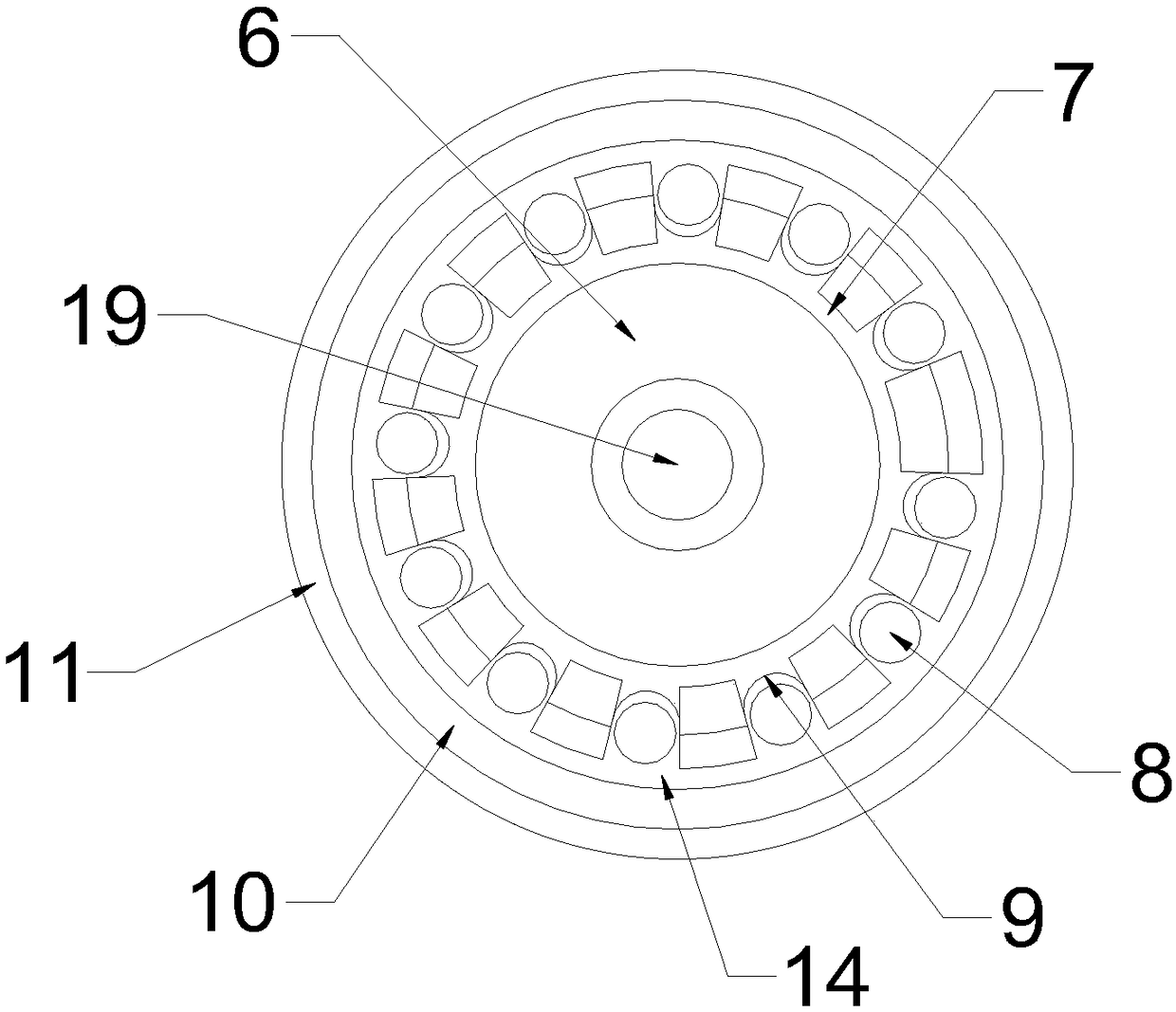

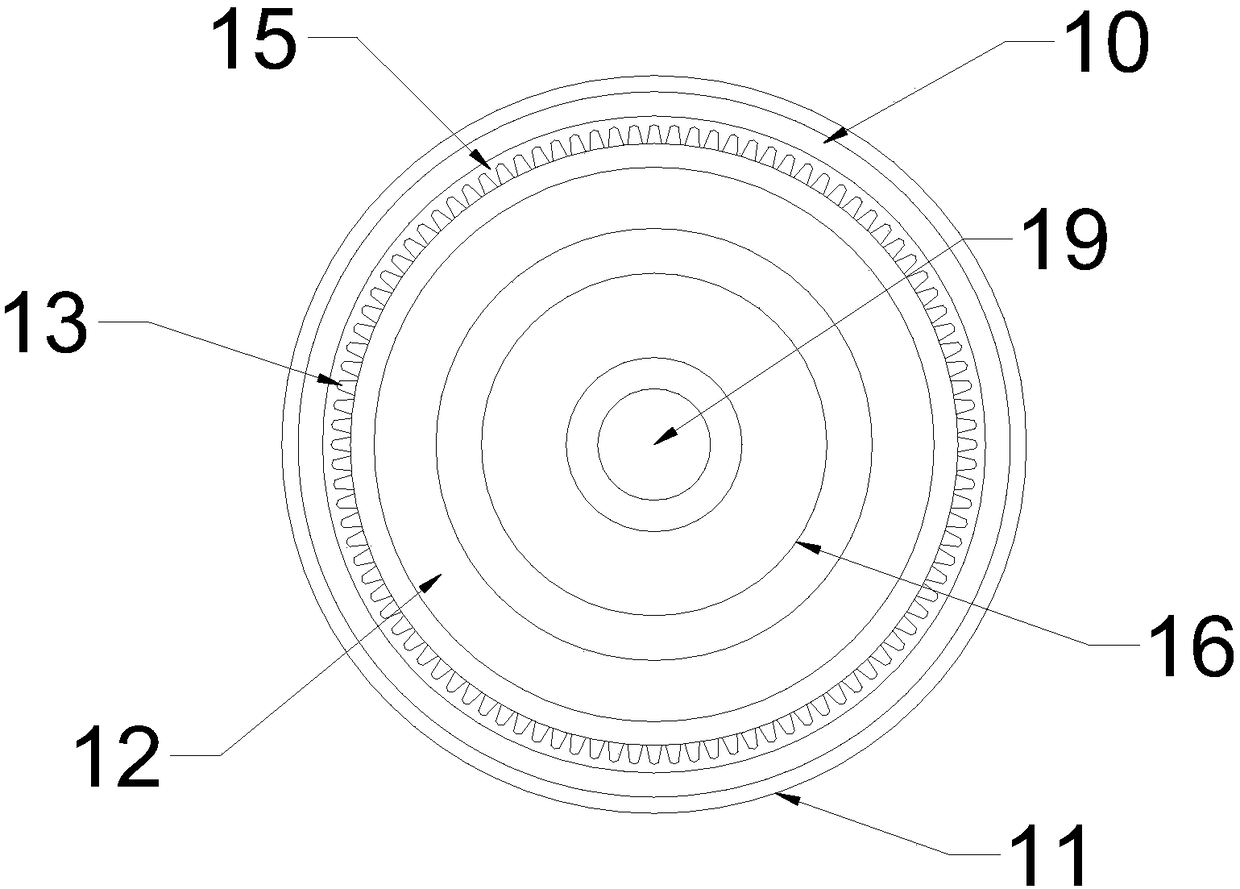

[0021] see Figure 1-3 , a ball-type vertical high-efficiency multi-stage grinding device, including a feeding hopper 1, a pre-crushing sprocket set 2, a primary grinding wheel disc 7, a grinding cylinder 10, a casing 11, a secondary grinding disc 12 and a motor 20, The casing 11 is fixed on the frame 21, the inner wall of the casing 11 is fixed with a grinding cylinder 10, the casing 11 below the grinding cylinder 10 is set as a collecting cavity 17, and the casing 11 on the bottom side of the collecting cavity 17 Connect the discharge pipe 18, the discharge pipe 18 is used to discharge the material in the collection chamber 17; the top of the casing 11 is connected to the feeding hopper 1, and the bottom end of the feeding hopper 1 is equipped with a pre-crushing sprocket group 2 inside.

[0022] The pre-crushing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com