Minced fillet production waste recovery device

A recycling device and waste technology are applied in the field of surimi production waste recycling devices, which can solve the problems of low drying efficiency, inability to sterilize and sterilize, and good pulverization effect, achieve good pulverization effect, realize effective utilization, and reduce the content of effect of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

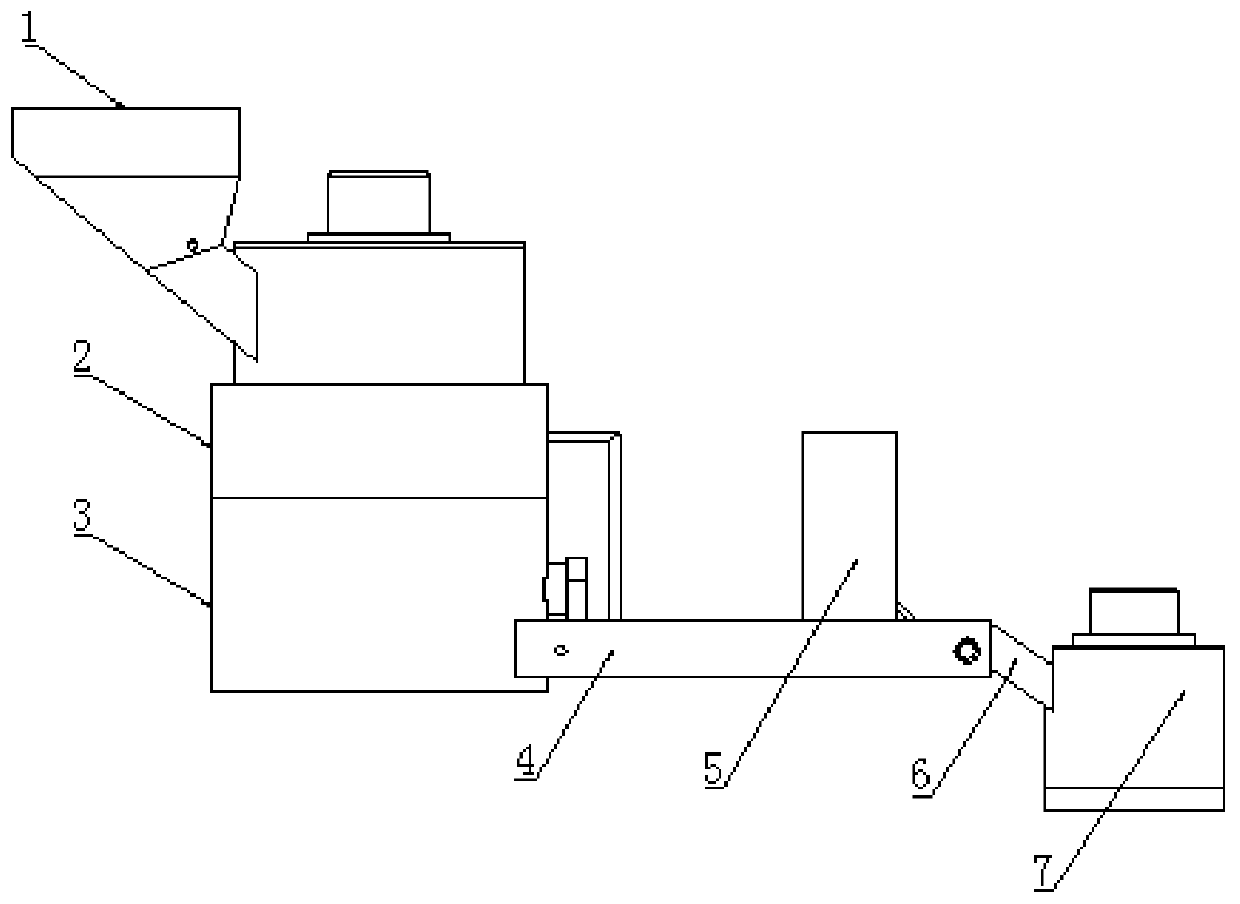

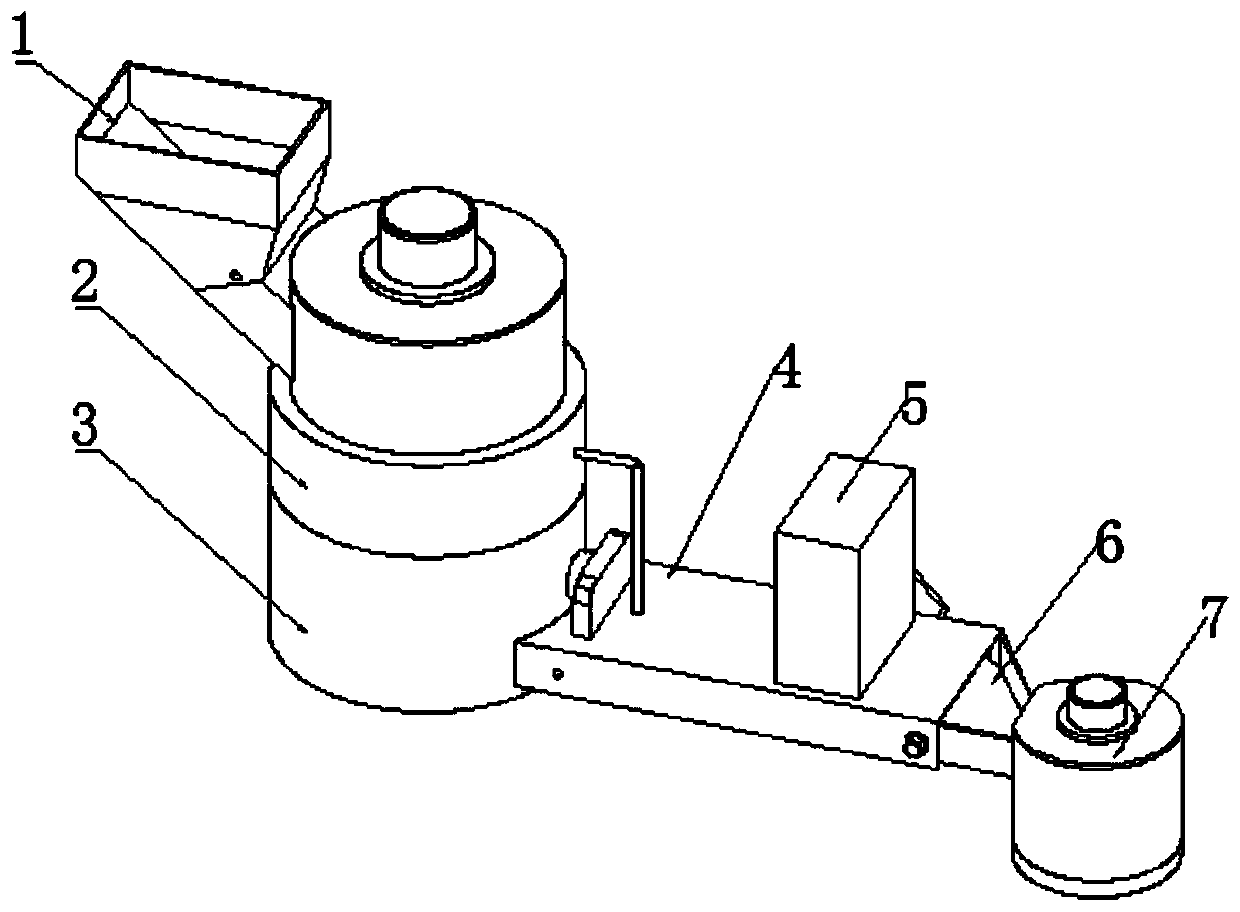

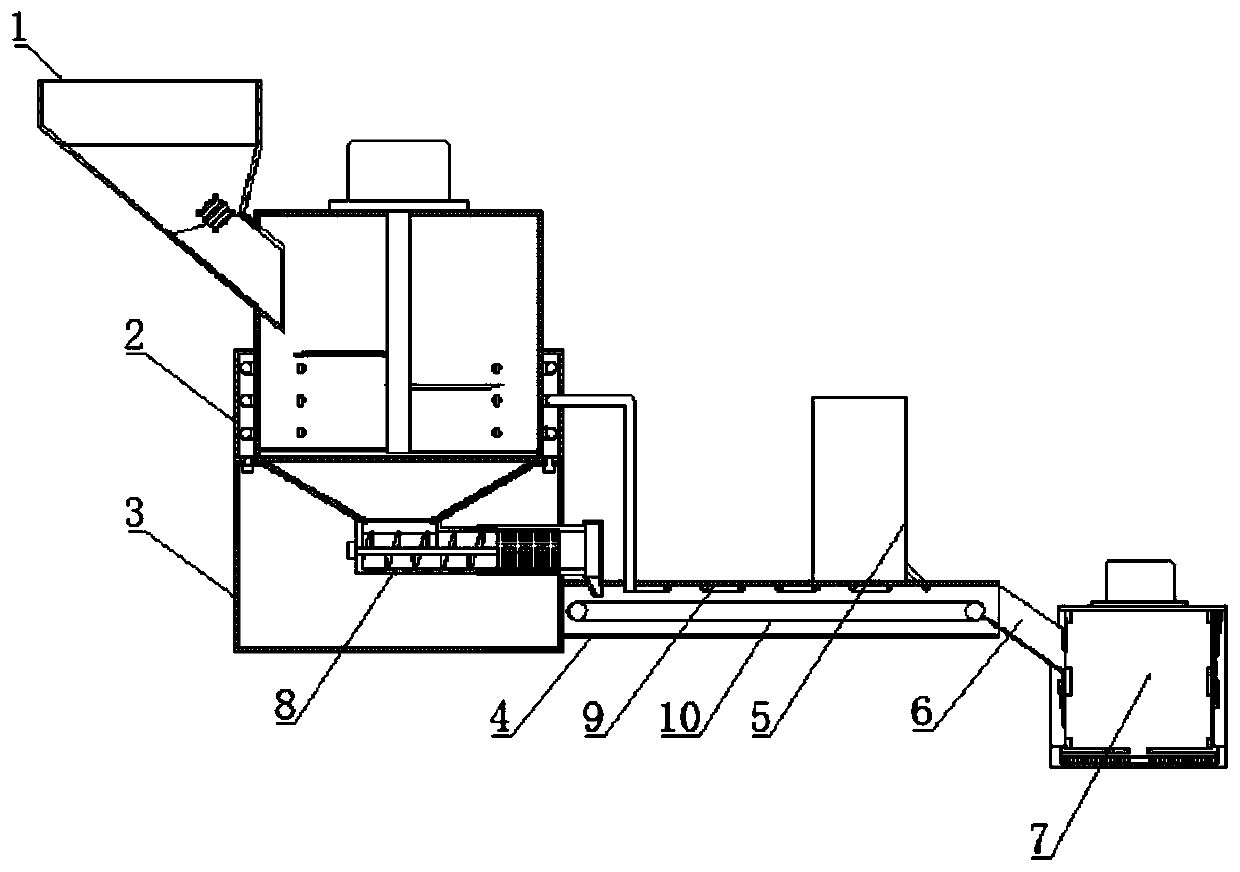

[0032] Example 1, please refer to figure 1 with figure 2 , a surimi production waste recovery device, comprising a feeding mechanism 1, a crushing mechanism 2 and a steam generator 5, the feeding mechanism 1 is arranged on the upper left of the crushing mechanism 2, and the feeding mechanism 1 and the crushing mechanism 2 are connected and arranged, The automatic feeding of the crushing mechanism 2 is realized through the feeding mechanism 1. A waste liquid collection tube 3 is arranged directly below the crushing mechanism 2. The upper port of the waste liquid collection tube 3 is socketed and connected with the crushing mechanism 2. The waste liquid collected by the set The cylinder 3 realizes the collection of waste liquid in the waste to facilitate centralized treatment. The right end surface of the waste liquid collection cylinder 3 is fixedly connected with a drying box 4 near the lower end, and a material guide groove 6 is arranged at the outlet of the right end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com