Textile processing device

A processing device and textile technology, applied in textile processing machine accessories, textiles and papermaking, equipment configuration for processing textile materials, etc., can solve the problem of aggravating the wrinkle degree of textile fabrics, increasing the time for grinding textile fabrics, the difficulty of grinding textile fabrics, and the difficulty of coating color particles Precipitation and other problems, to reduce the possibility of re-precipitation, improve uniformity, improve the effect of dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further detailed explanation through specific implementation mode below:

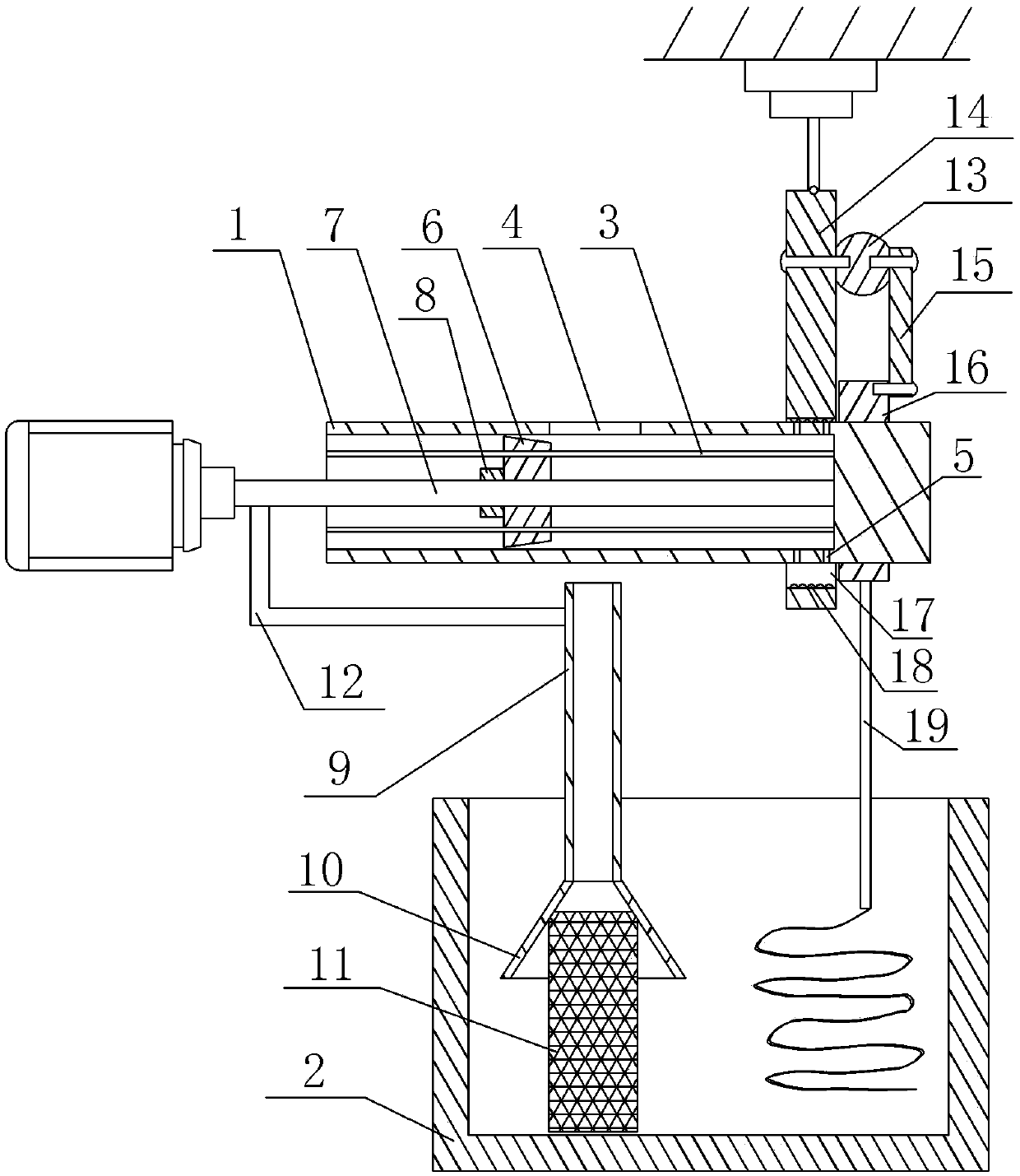

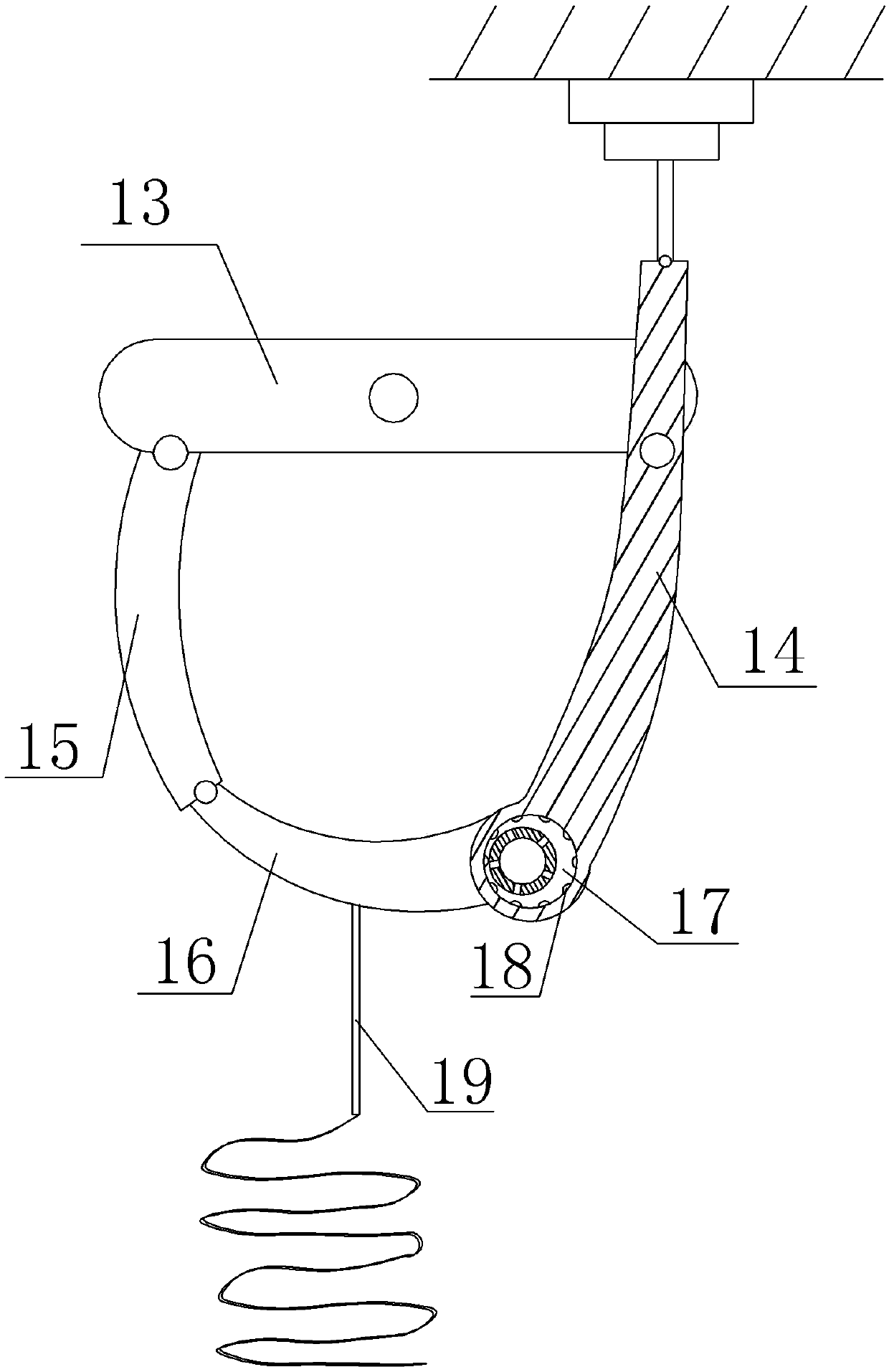

[0017] The reference signs in the drawings of the description include: positioning grinding tube 1, dyeing pool 2, limit rod 3, feed hole 4, discharge hole 5, extruding disc 6, screw rod 7, nut seat 8, feed Pipe 9, funnel 10, filter plate 11, bending rod 12, support rod 13, grinding rod 14, adjustment rod 15, shaking rod 16, circular hole 17, protrusion 18, clamping rod 19.

[0018] Such as figure 1 The textile processing device shown includes a positioning grinding tube 1, a dyeing pool 2, a pushing and fishing mechanism and a shaking grinding mechanism. The dyeing pool 2 is located below the positioning grinding tube 1, and the positioning grinding tube 1 is fixed on the frame. The positioning grinding tube 1 includes a sealing end at the right end and an opening end at the left end. The sealing end of the positioning grinding tube 1 is axially fixed with two limiters Position rod 3; a feed h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com