Micron-sized ultrafine iron powder preparation method

An ultra-fine iron powder and micron-level technology, which is applied in the field of preparation of micron-level ultra-fine iron powder, can solve the problems of preparing micron-level ultra-fine iron powder, etc., and achieves fast reduction speed, improved pulverization effect and high reduction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The preparation process and steps of ultrafine iron powder in the present embodiment are as follows:

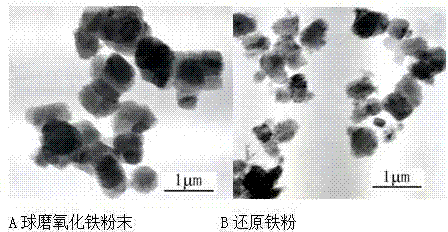

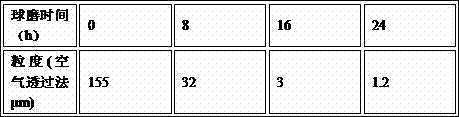

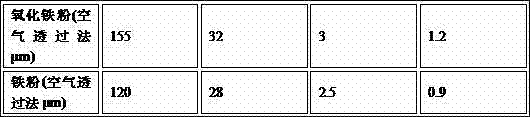

[0022] (1) Use the iron oxide scale powder separated from the iron surface layer of the incinerated garbage as raw material, after cleaning and magnetic separation (see Table 1 for its composition), add graphite at 0.5-1 (wt)% of the weight of the iron oxide scale powder, and another Add an appropriate amount of zinc stearate, carry out ball milling in a high-energy ball mill, and grind and pulverize to micronano iron oxide powder; graphite can be used as a reducing agent for iron oxide, and zinc stearate can be used as a process control agent; The oxygen content of the raw material powder is used as the measurement basis; the high-energy ball mill is a planetary ball mill; the ball milling process conditions are: the ball-to-material ratio is 4:1, the ball milling speed is 500 r / min, and the ball milling time is 8-24 hours. After ball milling, the powder was sieved to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com