Wood chip processing production system

A production system and wood chip technology, applied in wood processing equipment, manufacturing tools, grain processing, etc., can solve the problems of large crushed particles, intertwined wood fibers, poor crushing effect, etc., to achieve fine particles, reasonable arrangement, and better effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

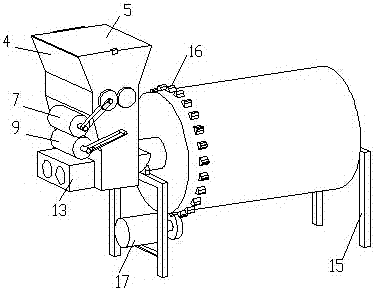

[0015] Please refer to the attached Figures 1 to 3 , the embodiment of the present invention includes:

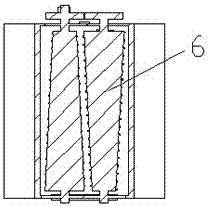

[0016] A sawdust processing production system includes a crushing chamber 1, a crushing chamber 2 and a ball mill barrel 3. The crushing chamber 1 is provided with a funnel-shaped feeding port 4, and a cover plate 5 for opening and closing is installed on the feeding port 4. The effect of the cover plate 5 can not only improve the safety of the equipment, but also prevent the wooden blocks from splashing out when they are crushed. In the crushing chamber 1, two opposing rollers 6 are arranged, and the rollers 6 are truncated cone-shaped sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com