Smashing and grinding device used in garbage fertilizer making system

A grinding device and garbage technology, applied in the direction of pressure inorganic powder coating, grain processing, etc., can solve problems such as unfavorable operation of fertilizer system, difficulty in separation and crushing, increase in cost, etc., and achieve good crushing and grinding effect, short cycle, increase The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

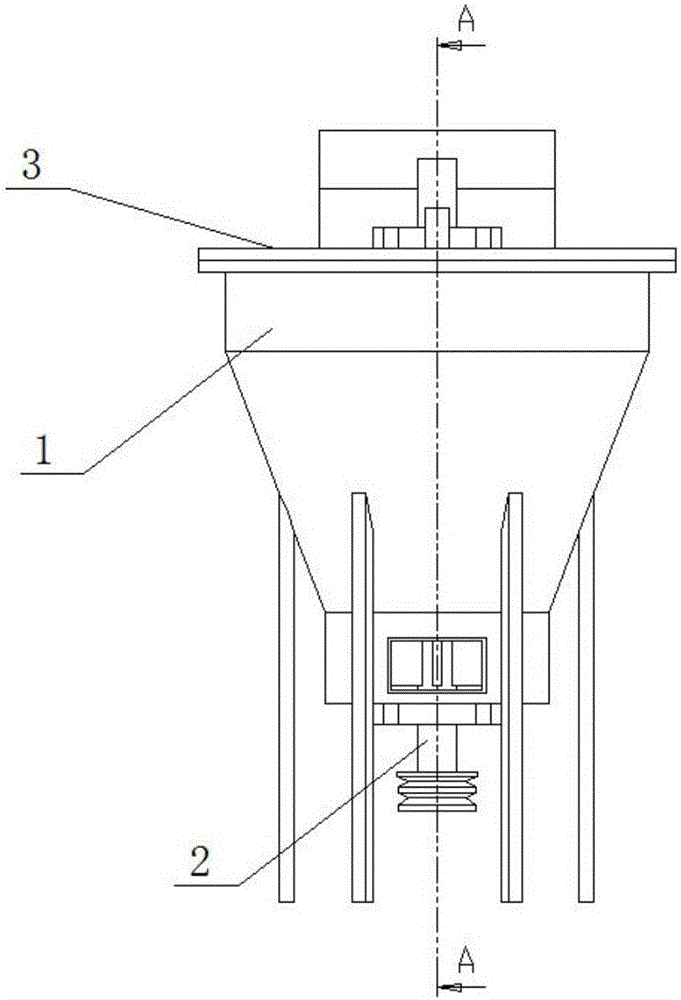

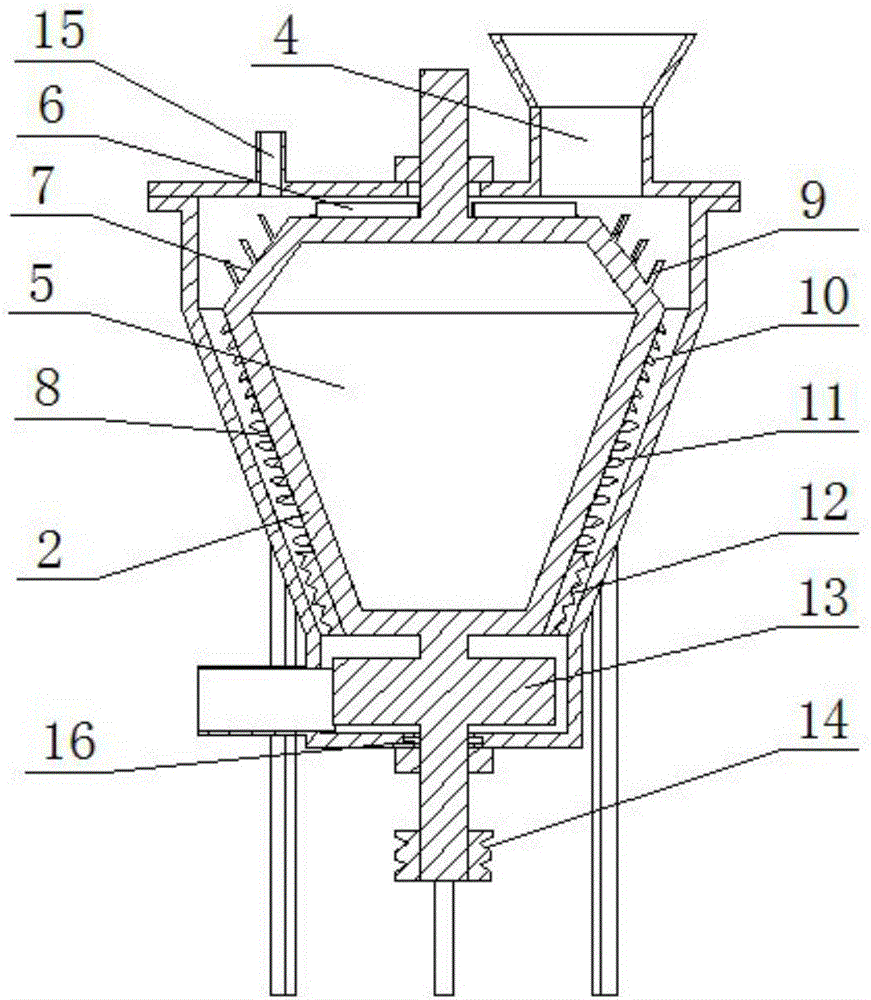

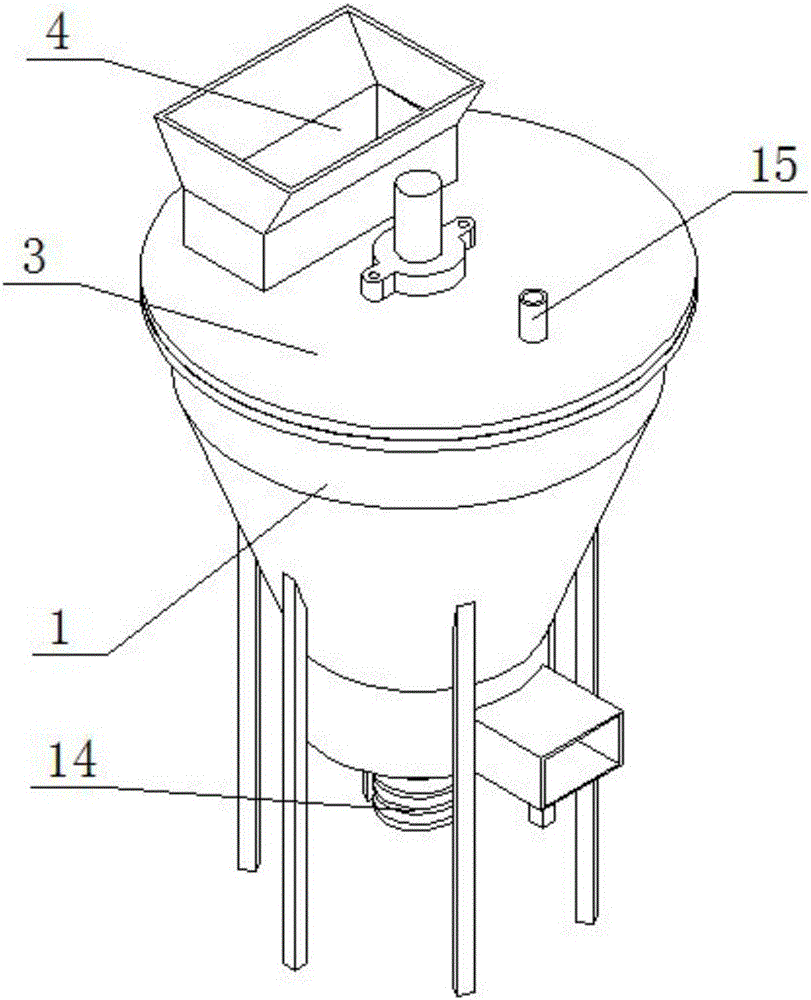

Embodiment 1

[0029] The crushing and grinding device used in the garbage fertilizer system provided by this embodiment includes a horizontally placed machine base 1, the cross section of the machine base 1 is in a "V" shape, and the inside of the machine base 1 is vertically provided with a crushing roller 2, The shape of the crushing roller 2 matches the machine base 1. The upper end of the machine base 1 is provided with an end cover 3 for fixing the crushing roller 2. The end cover 3 is provided with a feed port 4 and a water inlet 15. The inside of the crushing roller 2 is empty. The cavity 5 is horizontally provided with a uniform material plate 6 on the upper end surface of the crushing roller 2, and the outer surface of the crushing roller 2 is provided with a blanking surface 7 and a crushing surface 8 in sequence from top to bottom, and the blanking surface 7 and the crushing surface 8 are all inclined. The first crushing knife 9 is arranged on the cutting surface 7, and the cuttin...

Embodiment 2

[0037] The crushing and grinding device used in the garbage fertilizer system provided by this embodiment includes a horizontally placed machine base 1, the cross section of the machine base 1 is in a "V" shape, and the inside of the machine base 1 is vertically provided with a crushing roller 2, The shape of the crushing roller 2 matches the machine base 1. The upper end of the machine base 1 is provided with an end cover 3 for fixing the crushing roller 2. The end cover 3 is provided with a feed port 4 and a water inlet 15. The inside of the crushing roller 2 is empty. The cavity 5 is horizontally provided with a uniform material plate 6 on the upper end surface of the crushing roller 2, and the outer surface of the crushing roller 2 is provided with a blanking surface 7 and a crushing surface 8 in sequence from top to bottom, and the blanking surface 7 and the crushing surface 8 are all inclined. The first crushing knife 9 is arranged on the cutting surface 7, and the cuttin...

Embodiment 3

[0045] The crushing and grinding device used in the garbage fertilizer system provided by this embodiment includes a horizontally placed machine base 1, the cross section of the machine base 1 is in a "V" shape, and the inside of the machine base 1 is vertically provided with a crushing roller 2, The shape of the crushing roller 2 matches the machine base 1. The upper end of the machine base 1 is provided with an end cover 3 for fixing the crushing roller 2. The end cover 3 is provided with a feed port 4 and a water inlet 15. The inside of the crushing roller 2 is empty. The cavity 5 is horizontally provided with a uniform material plate 6 on the upper end surface of the crushing roller 2, and the outer surface of the crushing roller 2 is provided with a blanking surface 7 and a crushing surface 8 in sequence from top to bottom, and the blanking surface 7 and the crushing surface 8 are all inclined. The first crushing knife 9 is arranged on the cutting surface 7, and the cuttin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com