Coating smashing and grinding device

A grinding device and coating technology, applied in the direction of grain processing, etc., can solve the problems that the crushing particle size cannot meet the use requirements, reduce the production efficiency of the enterprise, and the crushing effect is not good, etc., and achieve high grinding and crushing effect, strong practicability, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

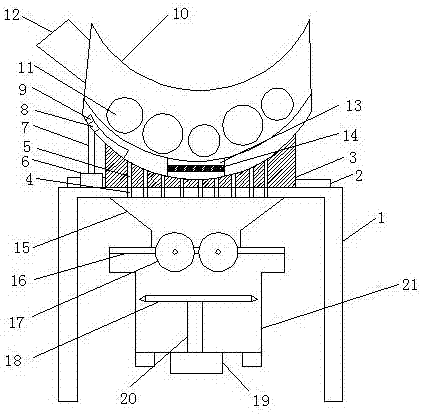

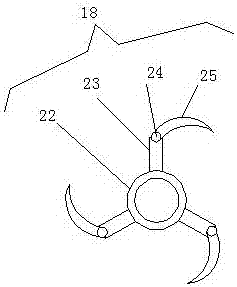

[0012] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0013] refer to Figure 1-2 , a paint crushing and grinding device, including a bracket 1, the upper end of the bracket 1 is provided with a support seat 3, the bracket 1 is provided with a limit block 2, and the support seat 3 is located between the limit blocks 2, which can be better fixed and will not deviation.

[0014] The upper end of the support base 3 is arc-shaped, and the upper end of the support base 3 is provided with a housing 10 matched therewith, the support base 3 is equidistantly provided with a plurality of second through holes 5, and the bracket 1 is provided with the second through holes 5. The first through hole 4 matched with the through hole 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com