Straw recycling system

A technology of straw and recycling box, applied in the application, cutting equipment, agricultural machinery and implements, etc., can solve the problems of uneconomical, affecting the strength of concrete, low bonding force of cementitious materials, etc., to increase frictional resistance and increase bonding force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

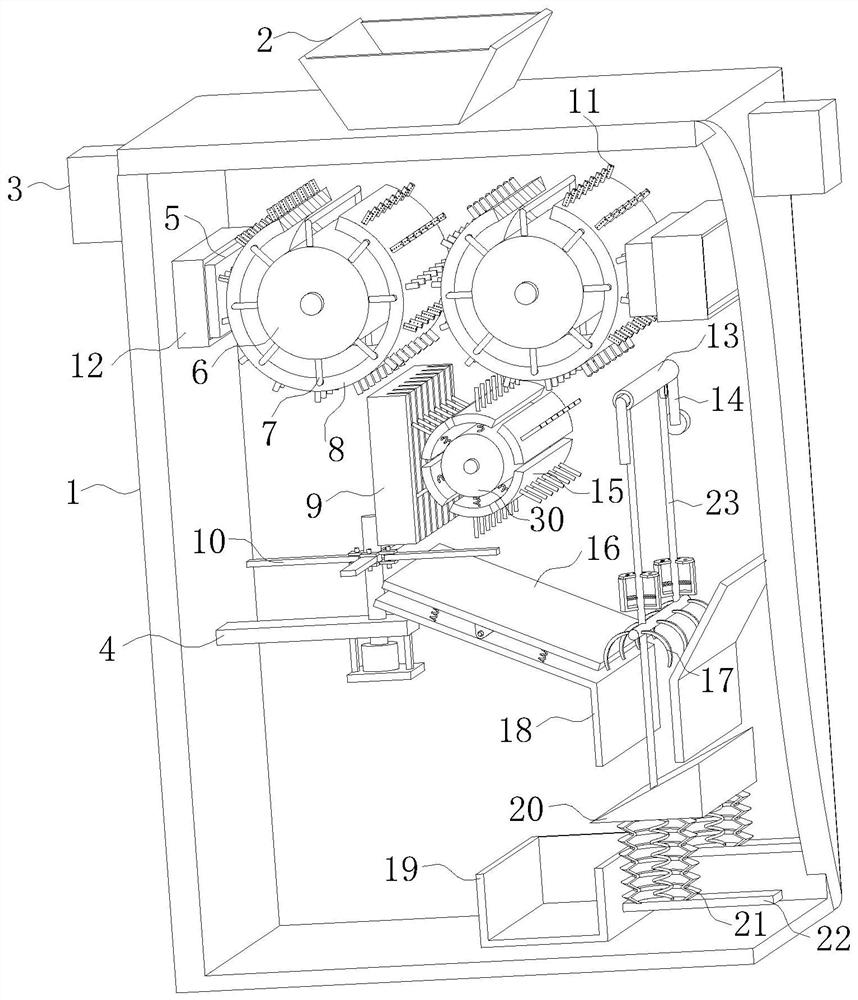

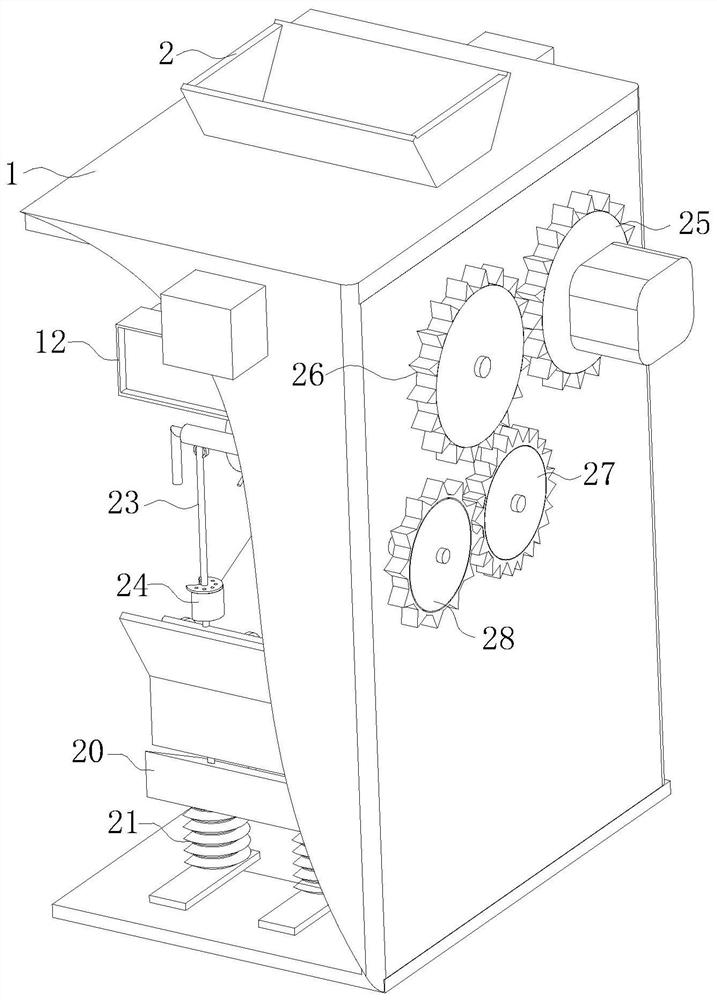

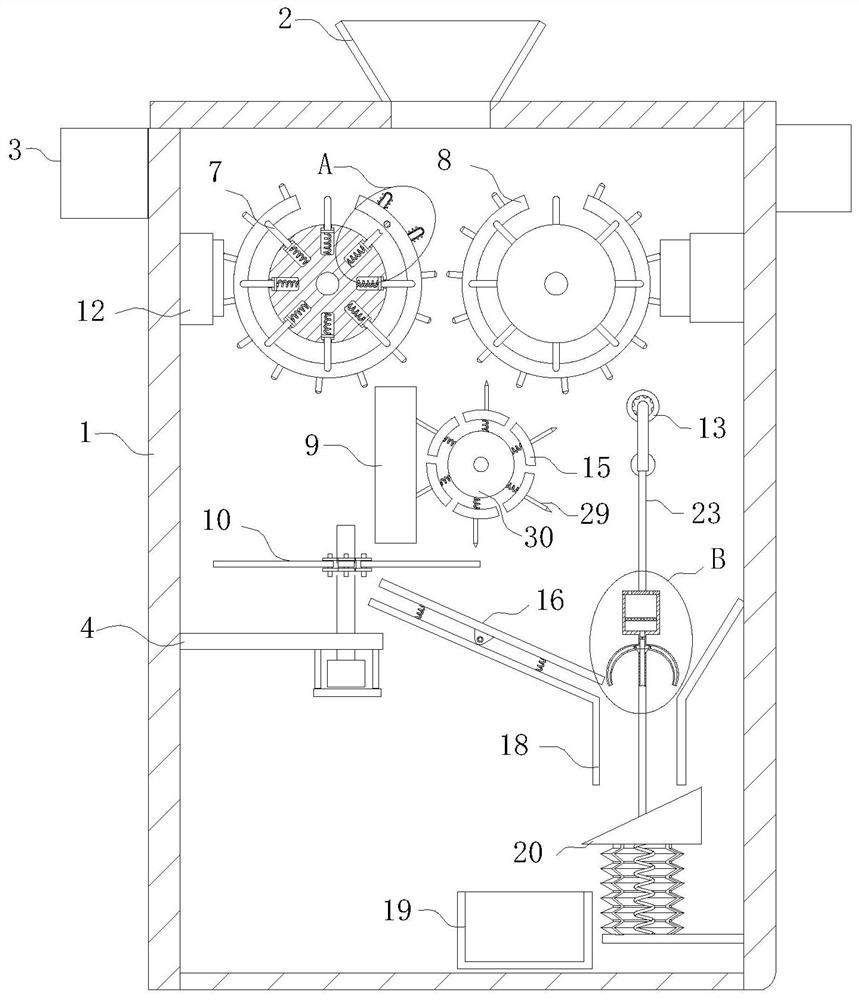

[0029] As an embodiment of the present invention, the acceleration circular gear 27 is meshed with the deceleration circular gear 28 for transmission; the rotating shaft of the deceleration circular gear 28 penetrates the interior of the recovery box 1 and is fixedly connected with one end of the U-shaped rotating rod 14; The U-shaped rotating rod 14 faces the outlet of the discharge chute 18; the horizontal rod of the U-shaped rotating rod 14 is provided with a movable sleeve 13; Fixed connection; the other end of the hollow hose 23 passes through the through hole on the mounting rod 38 and is fixedly connected to the surface of the right mounting plate 22 by a spring; the right mounting plate 22 is fixedly installed on the right side wall of the recovery box 1 The inner wall of the through hole on the described installation rod 38 is fixedly bonded with the outer edge of the hollow hose 23; the left and right sides edges of the described installation rod 38 are fixedly provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com