Robot grinding machining production line

A production line and robot technology, applied in the direction of grinding workpiece supports, metal processing equipment, grinding machines, etc., can solve the problems of staying in the conceptual stage, etc., and achieve the effects of convenient use, high processing efficiency and processing accuracy, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

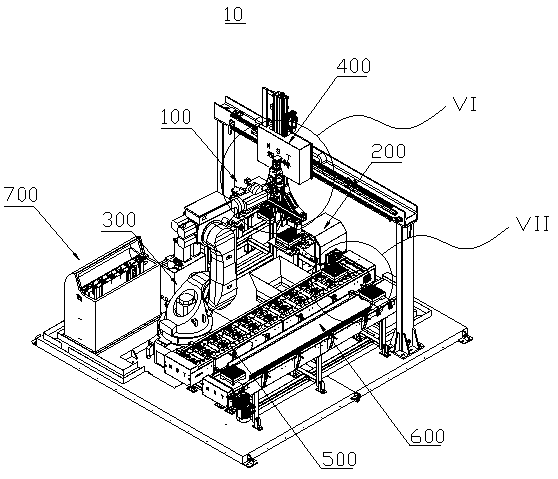

[0036] A kind of robot polishing processing production line 10, refer to figure 1 As shown, it includes a turning and shifting device 100 , a grinding and fixing device 200 , a grinding robot arm 300 , a parts transfer device 400 , an infeed conveyor belt 500 , and an outfeed conveyor belt 600 .

[0037] Wherein, the turning and shifting device 100, the polishing and fixing device 200, the feeding conveyor belt 500, and the discharging conveyor belt 600 are arranged side by side in sequence; There is a grinding operation area for fixing the parts 800, the grinding robot arm 300 is located in front of the grinding operation area, and faces the grinding operation area; the parts transfer device 400 includes a transfer track 410, and a transfer slide 420 that is slidably matched with the transfer track 410. The bottom of the sliding part 420 is provided with a grabbing part 440 for grabbing the part 800 , and the transfer track 410 is straddled above the turning operation area, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com