Guitar grinding device capable of adjusting grinding face

A technology for grinding surfaces and guitars, which is applied in the direction of grinding driving devices, grinding machine parts, grinding machines, etc., can solve the problems of difficult guitars and parts, complicated grinding operations, and heavy workload, and achieves simple and smooth guitars and parts. Simple operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

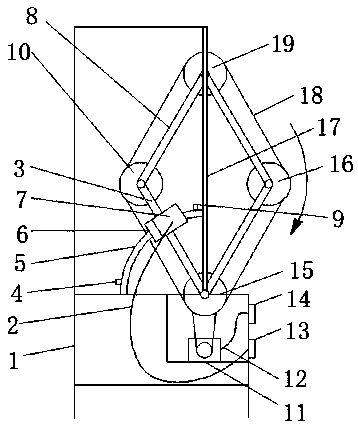

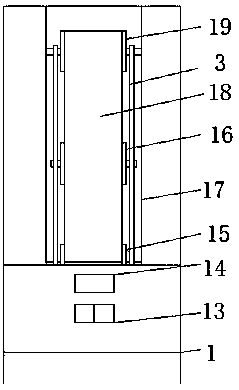

[0015] Example. A guitar grinding device capable of adjusting the grinding surface, consisting of Figure 1-2 As shown, it includes a frame 1, a first roller 15 is fixedly connected to the frame 1, a first motor 11 is connected to one side of the first roller 15, and a second motor 11 is connected to one side of the first roller 15 through a first movable connecting rod 3. The drum 10 is connected with the third drum 16 on both sides of the first drum 15 through the second movable connecting rod 8, and the fourth drum 19 is connected with the two sides of the second drum 10 and the third drum 16 through the second sliding connecting rod 8 respectively. Both sides of the fourth roller 19 are connected with vertical slide bars 17 via chute; the first roller 15 , the second roller 10 , the third rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com