Non-magnetic steel impact specimen grinding clamp and grinding method

An impact sample, non-magnetic technology, which is applied in the direction of grinding workpiece support, grinding/polishing equipment, grinding machine, etc., can solve the problems of poor processing effect and low efficiency of non-magnetic steel impact sample, and reduce the sample size. Effects of dimensional defect rate, accuracy improvement, and grinding efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

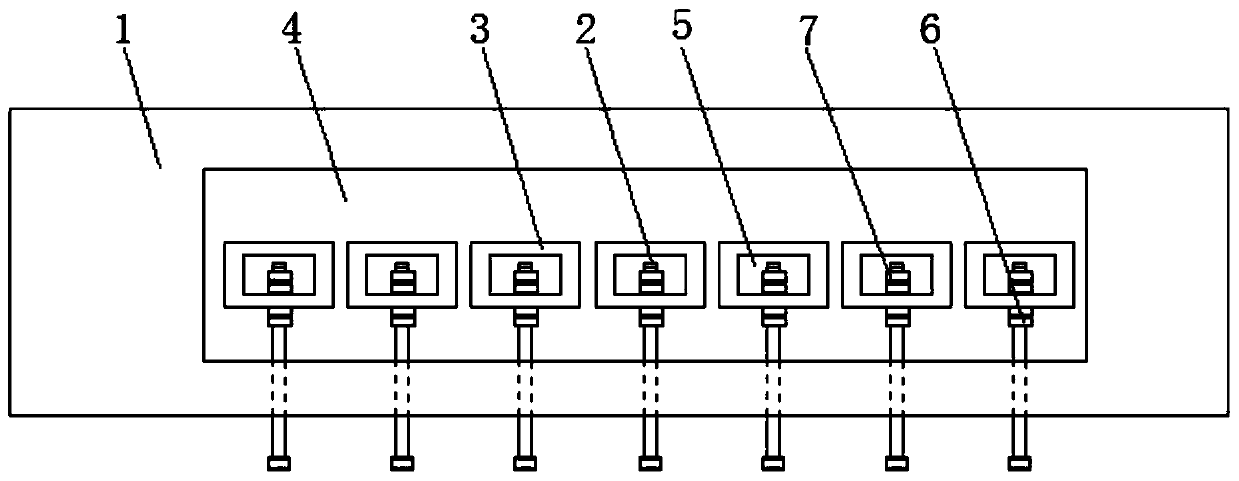

[0030] In an embodiment of the present invention, a non-magnetic steel impact sample grinding fixture is applied to a surface grinder, see figure 1 , the grinding fixture includes a base body 1, more than one adjustment rod 2 and top blocks 3 with the same number as the adjustment rods 2. And the structure of the top block 3 is described in detail:

[0031] The base body 1 is in the shape of a back shape as a whole, and there is a sample clamping area 4 for clamping the impact sample. The base body 1 is made of magnetic steel and can be adsorbed on the electromagnetic chuck of the surface grinder. The height of the base body 1 is smaller than that of the impact sample. When grinding, the test surface of the impact sample protrudes from the entire fixture, which is beneficial to the grinding operation. The specific size of the base body 1 depends on the size of the electromagnetic chuck.

[0032] A plurality of adjustment rods 2 are installed in the base body 1 at intervals a...

Embodiment 2

[0045] Based on the same inventive concept, this embodiment provides a non-magnetic steel impact sample grinding method, using the non-magnetic steel impact sample grinding jig provided in the above embodiment to grind the impact sample, the method includes the following steps :

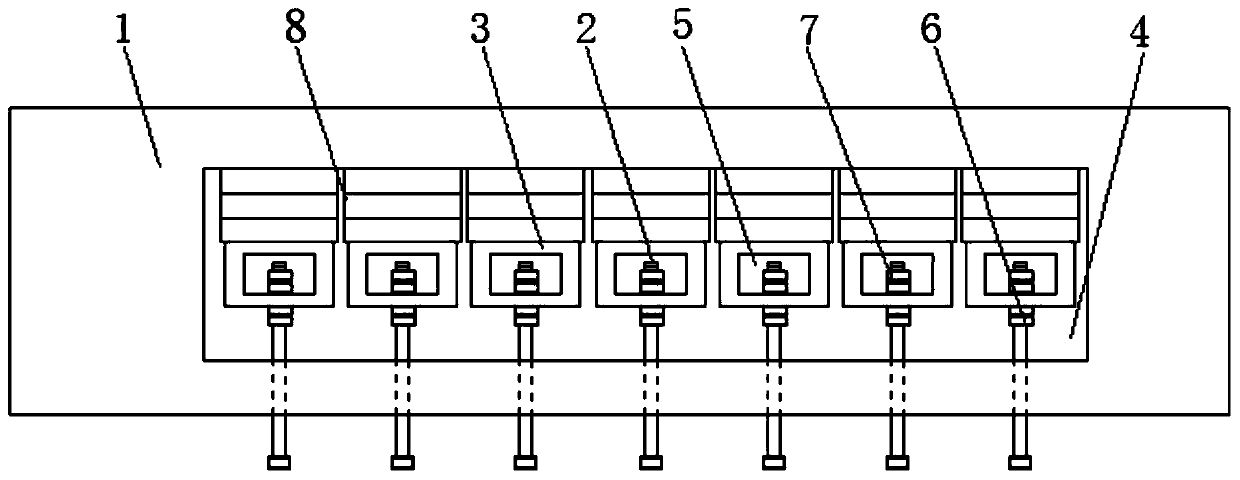

[0046] (1) Place the above-mentioned grinding fixture on the electromagnetic chuck of the surface grinder, place the impact sample 8 to be ground in the sample clamping area 4 with the test surface facing upward, and pass through the base body 1 and the top block 3 Clamp and fix the impact sample 8;

[0047] Since there are three impact samples in one group, in this embodiment, a group of three impact samples 8 of the same steel are clamped and fixed at the same time through the base body 1 and the top block 3, as figure 2 shown.

[0048] (2) The electromagnetic chuck is turned on, the substrate 1 is adsorbed and fixed on the electromagnetic chuck, the surface of the impact sample 8 is ground by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com