Plate edge burr grinding device

An edge burr and plate technology, which is applied in the field of plate edge burr grinding devices, can solve the problems of limited grinding operation, low grinding operation efficiency, and inability to clamp the plate in real time, so as to achieve the effect of improving grinding operation efficiency and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

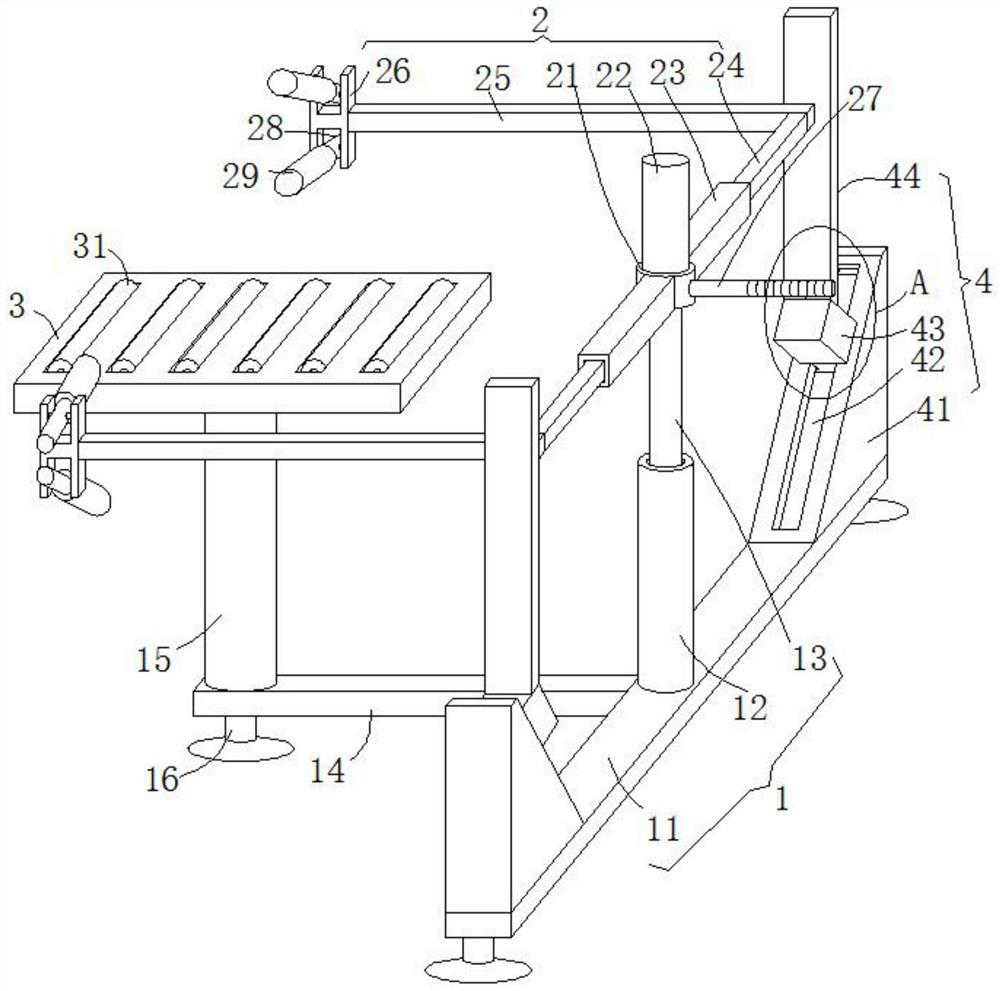

[0019]SeeFigure 1-3In this embodiment, the present embodiment provides a sheet of sheet-edge bulbs, including the support mechanism 1 and the grinding mechanism 2, the support mechanism 1 includes a transverse support beam 14 and a longitudinal support beam 11, and the lateral support beam 14 and the longitudinal support beam 11 T The type structure distribution, and mounting each other, the bottom end of the transverse support beam 14 is distinguished from one end of the longitudinal support beam 11 and the bottom ends of the longitudinal support beam 11 are fixedly provided with the support foot 16, providing the setting support foot 16, easy to It functions as a good support for the overall structure, and the upper end of the longitudinal support beam 11 is perpendicular to the buffer cylinder 12, and the top end of the buffer cylinder 12 is opened with an inverted T-type card slot, and the inside of the T-card slot is inverted. Sliding plugging with inverted T-type buffer 13;

[00...

Embodiment 2

[0027]Seefigure 1 Further improvements have been made on the basis of Example 1:

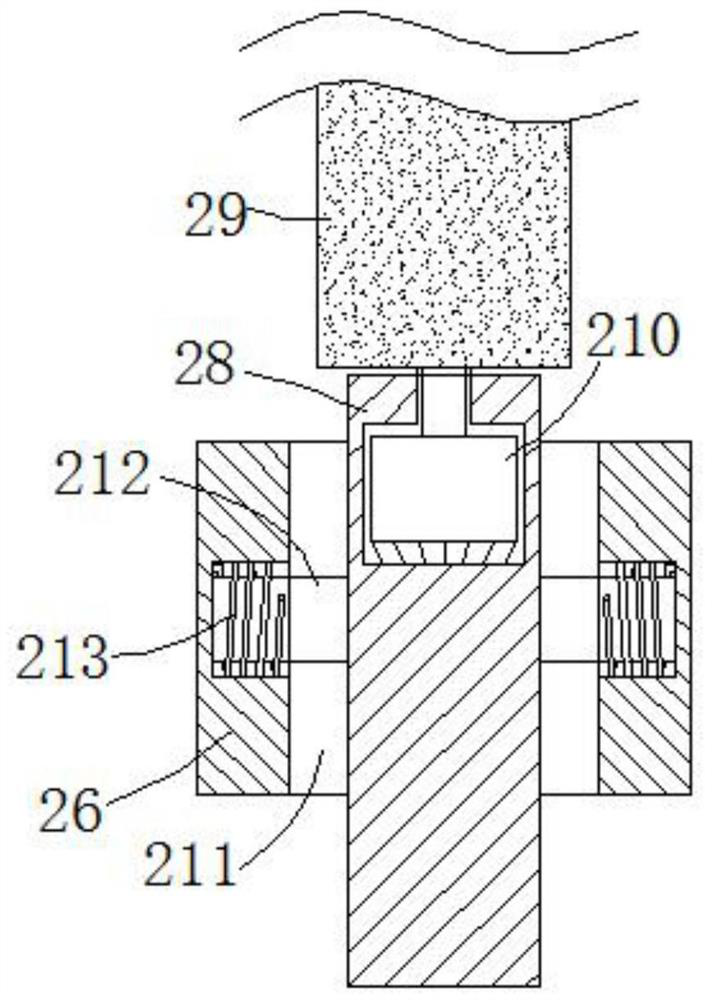

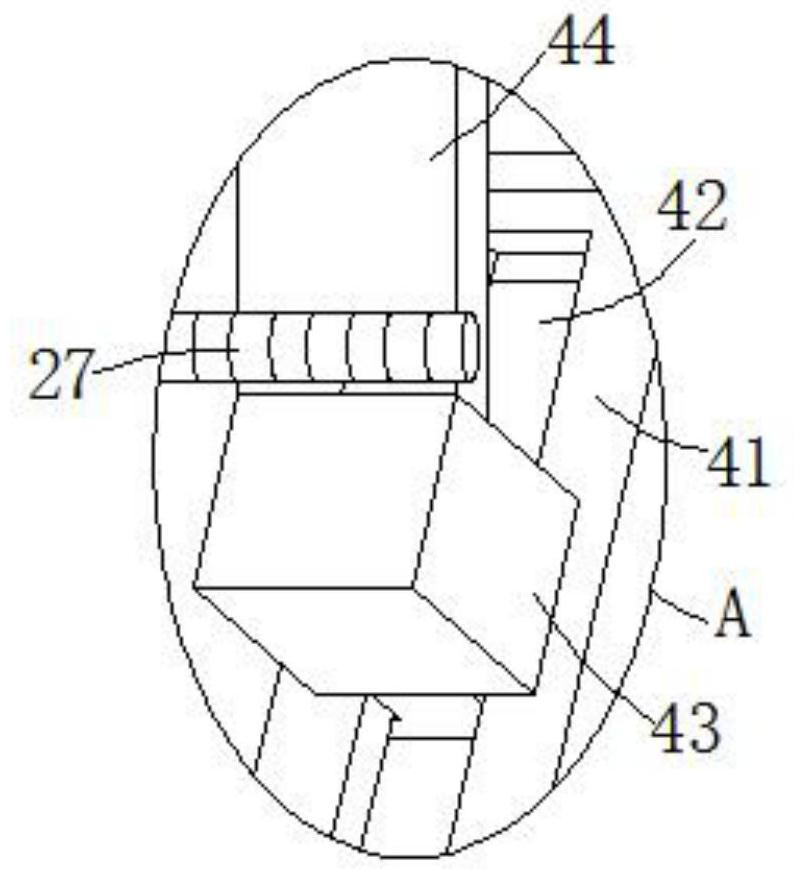

[0028]In order to solve the problem of how to adjust the grinding height of the entire grinding mechanism 2 and how to lower the grinding mechanism 2 real-time pressure, the upper end surface of the connecting seat 21 is vertically provided with a retaining column 22, and using the heavier column 22 to double weight. It is convenient to reduce the grinding mechanism 2 in real time, thereby facilitating the blade to avoid the slack due to slack during the process of polishing, and the radial side wall of the connecting seat 21 is provided with an operation handle 27, by setting the operating handle 27, Easy to assist up and down the reverse T-type buffer 13 freely slide along the inverted T-type cartridge of the buffer cylinder 12 to facilitate adjusting the height of the grinding mechanism 2 to achieve a sheet of different sizes and thickness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com