Building steel pipe cutting device

A technology of cutting device and steel pipe, applied in the direction of pipe shearing device, shearing device, accessory device of shearing machine, etc., can solve the problems of difficult grinding and cutting debris splashing, etc., and achieve the effect of easy grinding operation and restraining splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

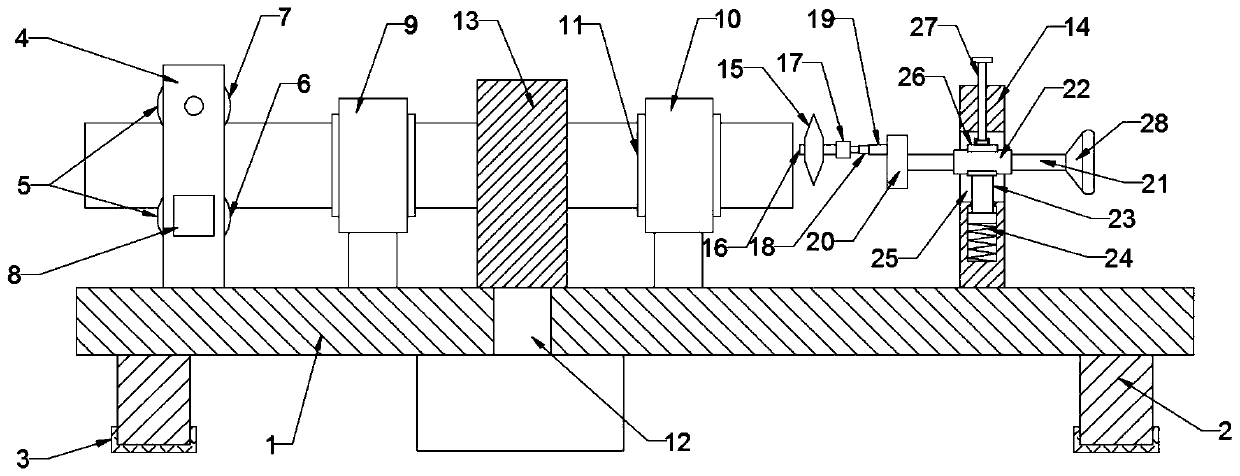

[0029] see Figure 1 to Figure 5 , a cutting device for building steel pipes, comprising a cutting machine tool 1, a feeding seat 4, a first positioning seat 9, a second positioning seat 10, a mounting frame 14 and a cutting piece 15, the bottom of the cutting machine tool 1 is equipped with a leg 2, the support The bottom of the leg 2 is provided with a shock-absorbing pad 3, which is made of rubber and fixed on the bottom of the leg 2, and is used to slow down the vibration from the cutting machine 1, which is equipped with a feeder along the same axis. Seat 4, first positioning seat 9, second positioning seat 10 and mounting frame 14,

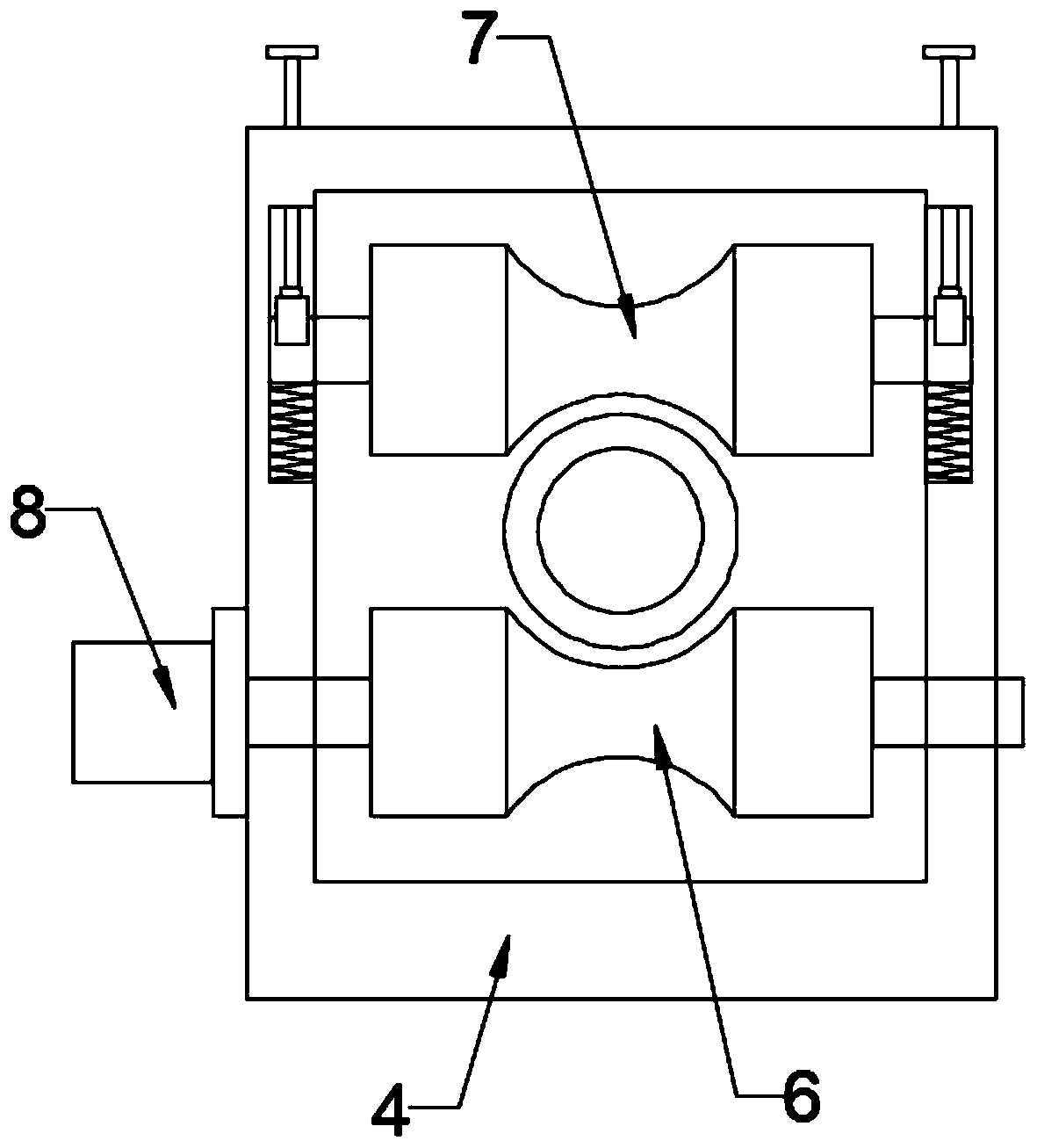

[0030] see image 3 As shown, the feeding roller 5 is installed in the feeding seat 4, and the feeding roller 5 includes a driving roller 6 and a driven roller 7, and the driving roller 6 and the driven roller 7 are arranged oppositely and are all rotatably mounted on the feeding seat 4 Inside, the driving roller 6 and the middle part of t...

Embodiment 2

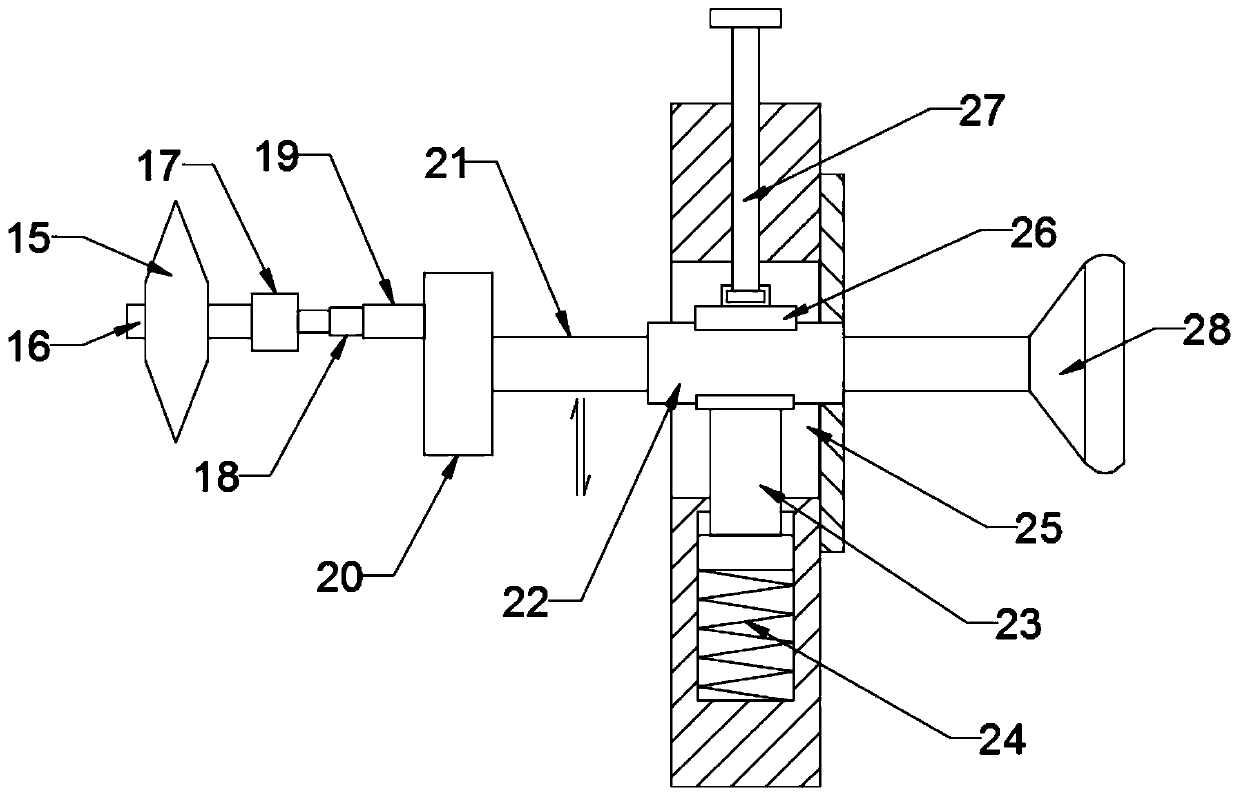

[0039] see figure 1 , Figure 3 ~ Figure 6 As shown, a construction steel pipe cutting device includes a cutting machine tool 1, a feeding seat 4, a first positioning seat 9, a second positioning seat 10, a mounting frame 14 and a cutting piece 15, and the mounting frame 14 is installed on the cutting machine tool 1 At one end, an axle sleeve 22 is installed on the mounting bracket 14, and the inner frame of the axle sleeve 22 is provided with a transmission shaft 21, and the end of the transmission shaft 21 near the second positioning seat 10 is connected to the eccentric wheel 20, and the eccentric position of the eccentric wheel 20 is equipped with a cylinder 19, and the cylinder The piston rod 18 front end of 19 is equipped with cutting motor 17, and cutting piece 15 is installed on the rotating shaft 16 of cutting motor 17, and the diameter of cutting piece 15 is less than the internal diameter of steel pipe;

[0040] Different from Embodiment 1, the end of the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com