Swinging laser-ultrasonic hybrid welding method

A hybrid welding and laser technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as forming defects, achieve the effect of reducing volume, good protection effect, and avoiding mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

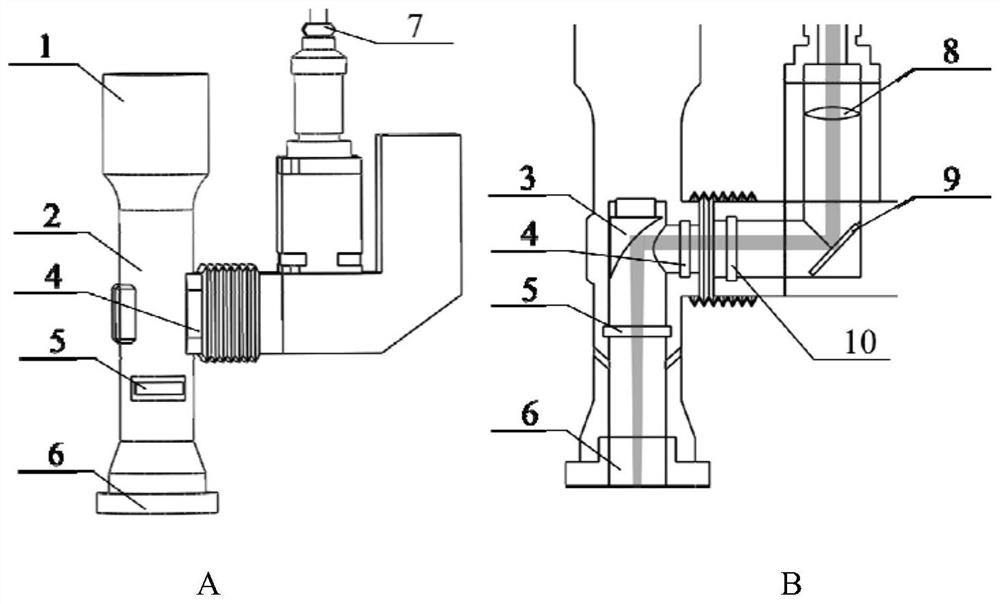

Method used

Image

Examples

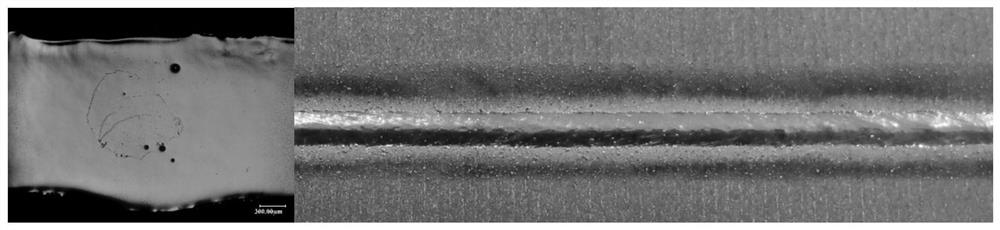

Embodiment 1

[0039] Conventional swing laser welding welds 2mm thick titanium alloy butt joints:

[0040] Step 1: process the parts to be welded of the workpiece to the required accuracy as required, and grind or clean the surfaces on both sides of the workpiece after processing;

[0041] Step 2: fixing the workpiece to be welded after grinding or cleaning on the welding fixture;

[0042] Step 3: The laser defocus is 0mm, the laser power is 1800W, the welding speed is 1.0m / min, the laser swing frequency is 200Hz, the swing amplitude is 2mm, the shielding gas is Ar gas, and the flow rate is 20L / min;

[0043] Step 4: In the actual welding process, the robot integrated system is used to control the welding process parameters. First, the laser is controlled to emit laser light and swing, and then the robot is controlled to make the composite welding head move to complete the welding process.

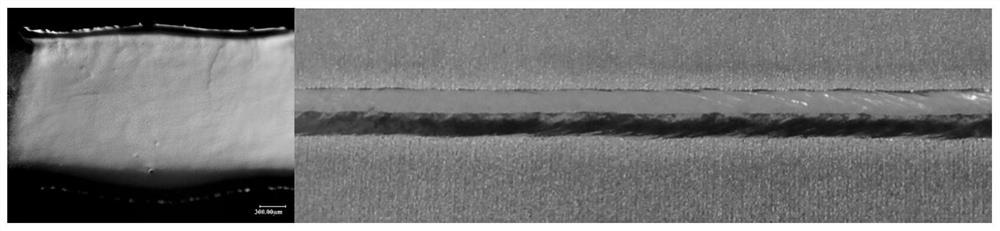

Embodiment 2

[0045] The method of the present invention welds a 2mm thick titanium alloy butt joint:

[0046] Step 1: process the parts to be welded of the workpiece to the required accuracy as required, and grind or clean the surfaces on both sides of the workpiece after processing;

[0047] Step 2: Fix the workpiece to be welded after grinding or cleaning on the welding fixture, the ultrasonic horn is perpendicular to the surface of the workpiece to be welded, and the distance below the end is 8cm from the surface of the workpiece to be welded;

[0048] Step 3: The laser defocus is 0mm, the laser power is 1800W, the welding speed is 1.0m / min, the laser swing frequency is 200Hz, the swing amplitude is 2mm, the ultrasonic vibration frequency is 30kHz, the vibration amplitude is 10μm, and the shielding gas is Ar gas , the flow rate is 40L / min;

[0049] Step 4: In the actual welding process, the robot integrated system is used to control the welding process parameters. First, ultrasonic vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com