Casting and grinding machine for thermal insulation material molding

A thermal insulation material and grinding machine technology, which is applied to ceramic molding machines, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve the problems of uneven thermal insulation walls, poor grinding quality, and low grinding efficiency, and improve grinding efficiency And quality, improve efficiency, improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

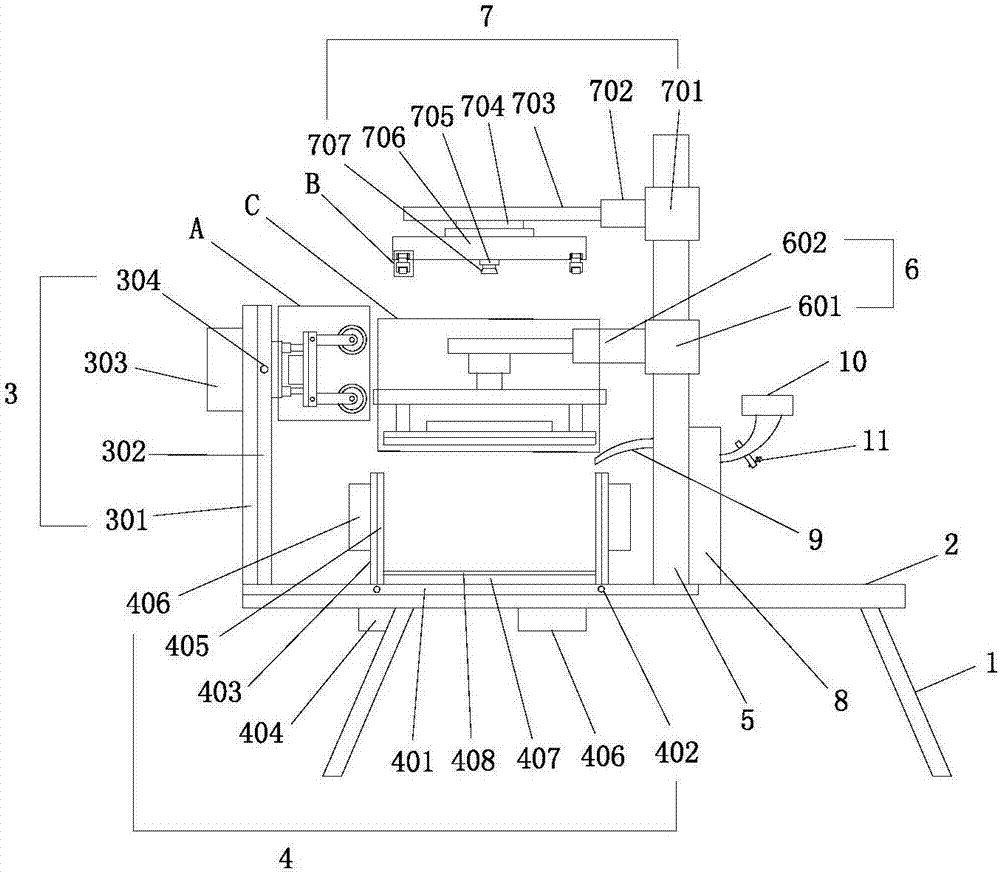

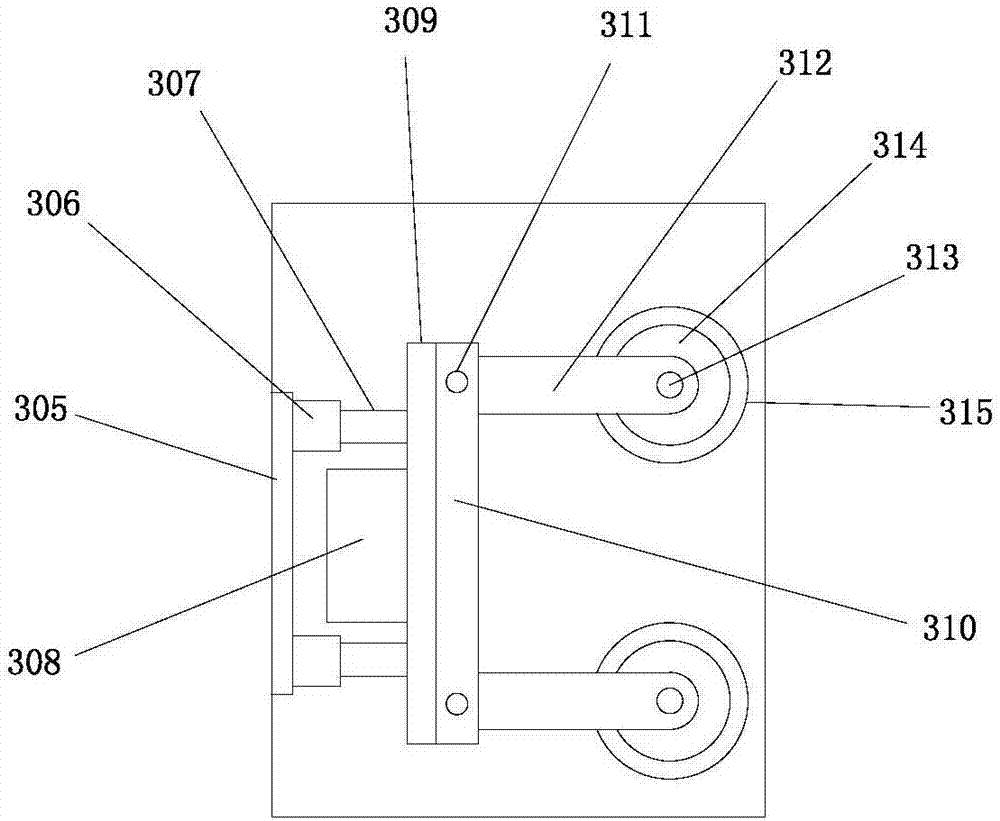

[0035] Such as Figure 1-4 As shown, the present invention provides a molding, casting and grinding machine for thermal insulation materials, including a base bracket 1, a base 2, a forming mechanism 4, a compression mechanism 6 and a grinding mechanism 3, a base is installed on the upper end of the base bracket, and a molding mechanism is installed on the upper end of the base, forming A compression mechanism is arranged above the mechanism, a grinding mechanism is installed on one side of the compression mechanism, a first mounting column 5 is installed on the upper end of the base 2, a compression mechanism 6 is installed on the first mounting column 5, and the compression mechanism 6 includes a There are a first rotating shaft 601, a first piston 602, a first piston shaft 603, a fourth piston 604, a fourth piston shaft 605 and a third heating plate 609 on the mounting post, and the first rotating shaft 601 is far away from the first mounting post 5 One end of the first pis...

Embodiment 2

[0041] The difference between Embodiment 2 of the present invention and Embodiment 1 above is that.

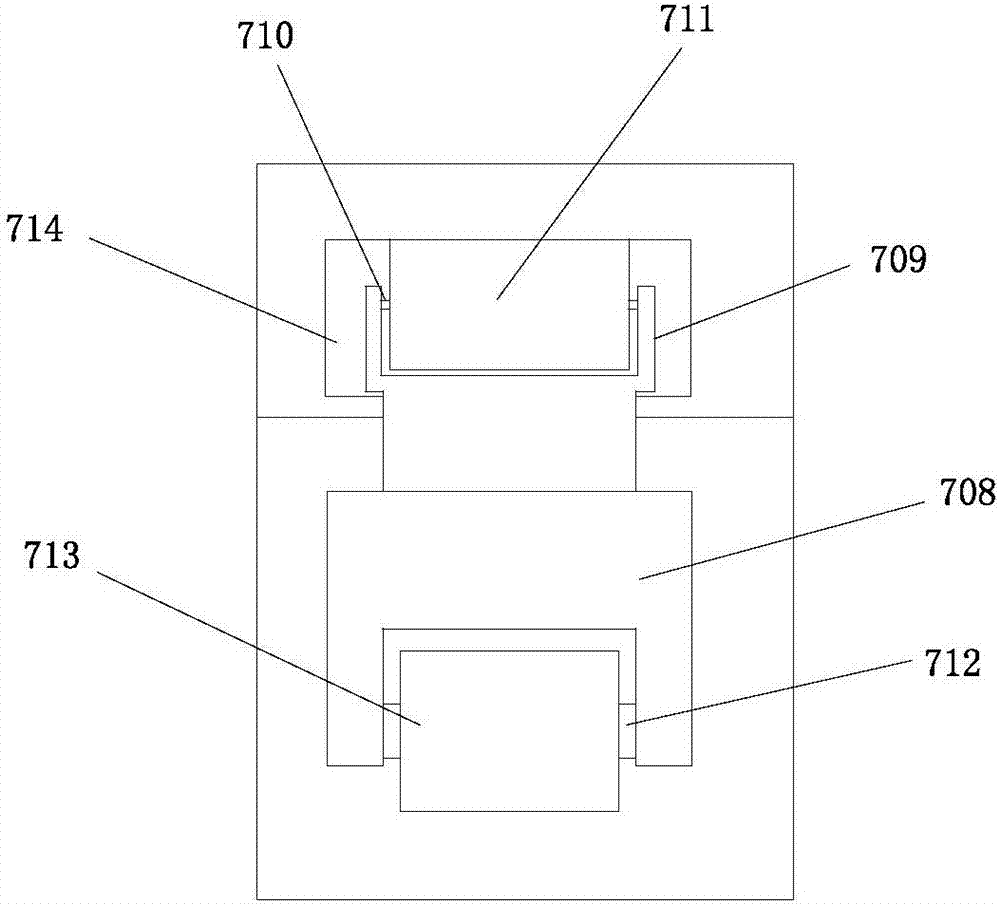

[0042] refer to Figure 5 and Figure 6 A first limiting plate 408 is installed on the lower end of the first heating plate mounting base 407, and a fifth piston 410 is installed on the end of the first limiting plate 408 away from the first heating plate mounting base 407, and the fifth piston 410 is far away from the first limiting plate. One end of the positioning plate 408 is equipped with a fifth piston shaft 411, and the end of the fifth piston shaft 411 away from the fifth piston 410 is equipped with a second limiting plate 409, and the end of the second limiting plate 409 away from the fifth piston shaft 411 is equipped with a The sixth piston shaft 413 , the sixth piston 414 is mounted on the end of the sixth piston shaft 413 away from the second limiting plate 409 , and the fourth motor 415 is mounted on the lower end of the base 2 . By installing the first limitin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com