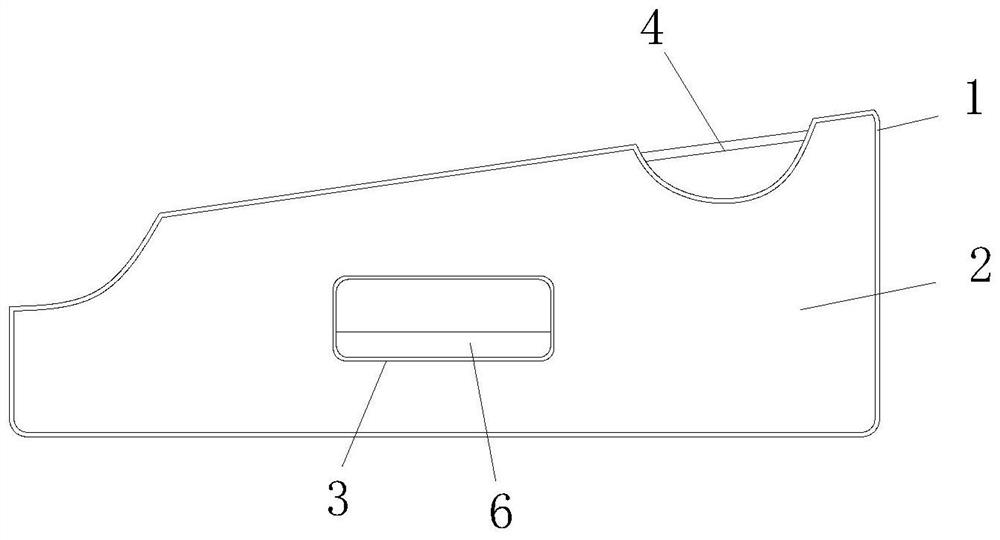

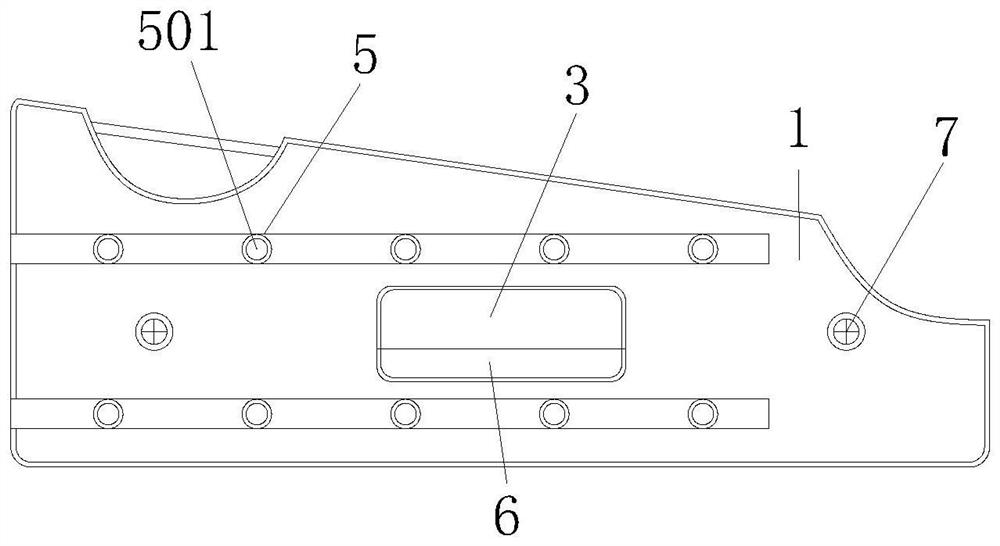

Light-weight plastic sheet for automobile lining

A plastic sheet, plastic sheet technology, applied in vehicle parts, upper structure, passenger space, etc., can solve the problems of water leakage in the cup, easy falling of items, affecting the working efficiency of auto parts, etc. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

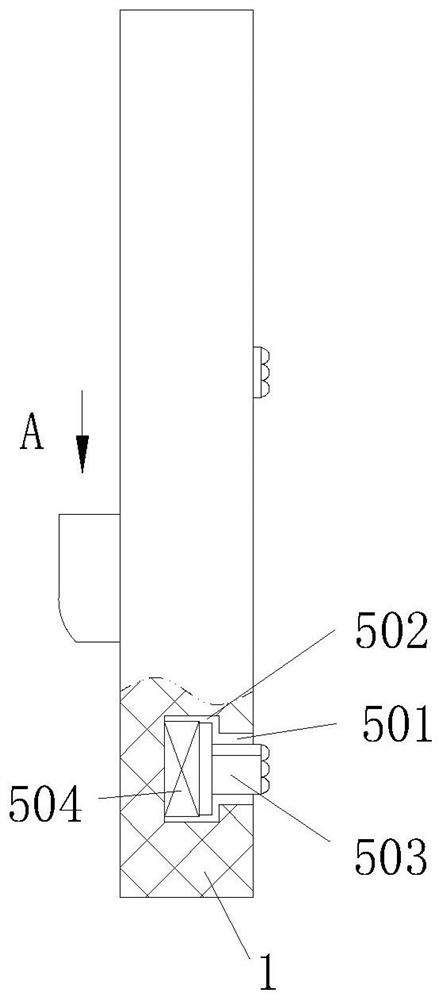

[0028] As an embodiment of the present invention, the storage tank 9 is provided with a through hole 86 on one side close to the cup groove 8; The lower end faces the anti-skid bag 83, and the higher end is located at the bottom of the storage groove 9. During work, there will inevitably be some water droplets remaining in the storage tank 9. At this time, through the provided through hole 86, the water droplets collected inside will flow downwards into the cup groove 8 under the action of its own weight, and the anti-skid bag 83 will be released. The jetted gas accelerates the flow of the airflow, so that the interior remains dry, and at the same time, the jetted gas from the anti-skid bag 83 will enter the storage tank 9 from the through hole 86 to clean up the impurities and water droplets that have not accumulated in the storage tank 9. Cleanliness is guaranteed.

[0029] As an embodiment of the present invention, an auxiliary module is installed in the storage slot 9; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com