Strip-shaped plate grinding device

A plate and bar-shaped technology, which is applied in the direction of grinding/polishing safety devices, grinding machines, grinding racks, etc., can solve the problems of low grinding efficiency and small grinding range, reduce labor, simplify grinding operations, and reduce labor costs. The effect of intensity

Active Publication Date: 2018-07-20

CHONGQING JIANAN IND & TRADE

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The object of the present invention is to provide a strip-shaped plate grinding device to solve the problems of small grinding range and low grinding efficiency of traditional grinding machines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

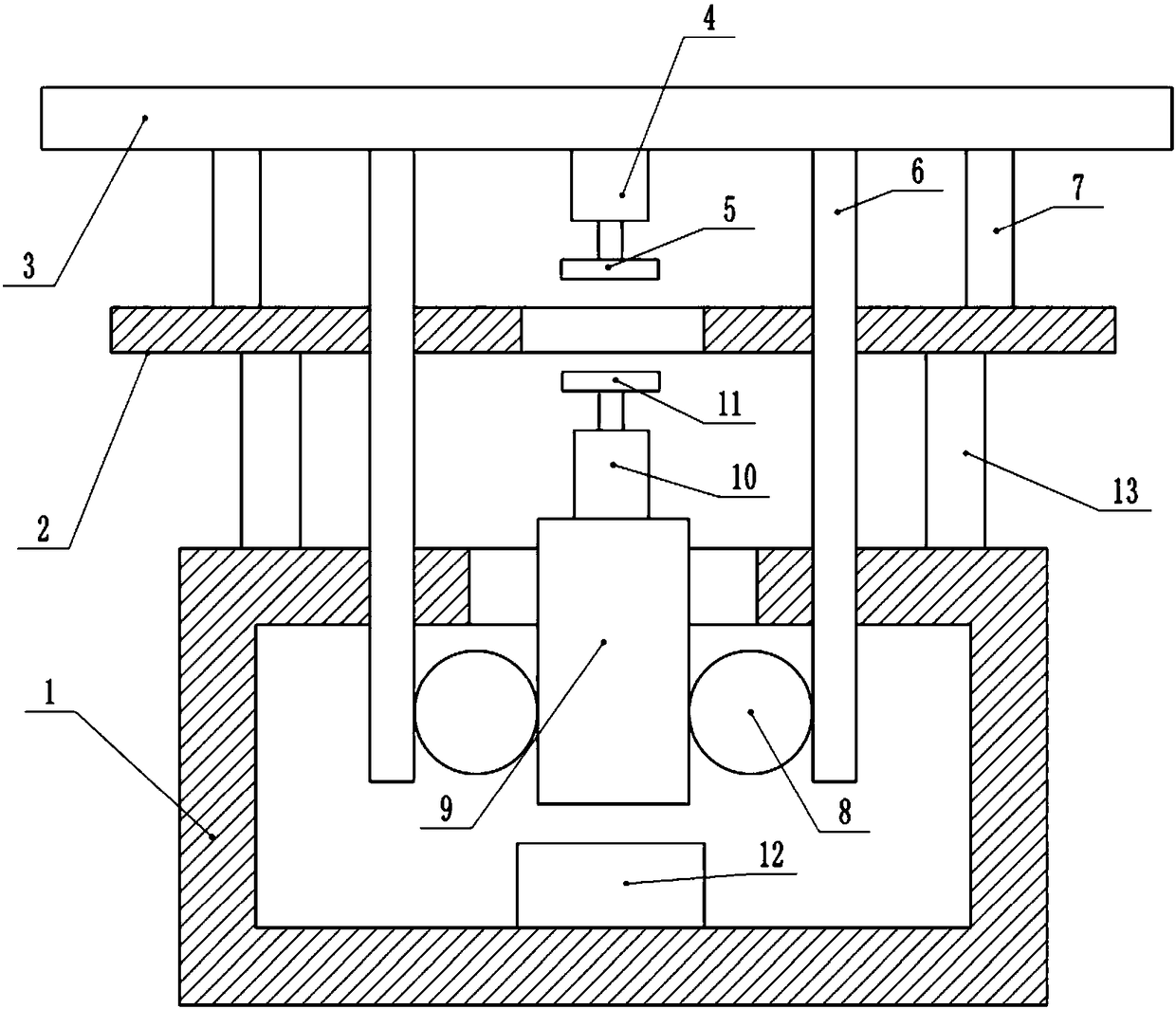

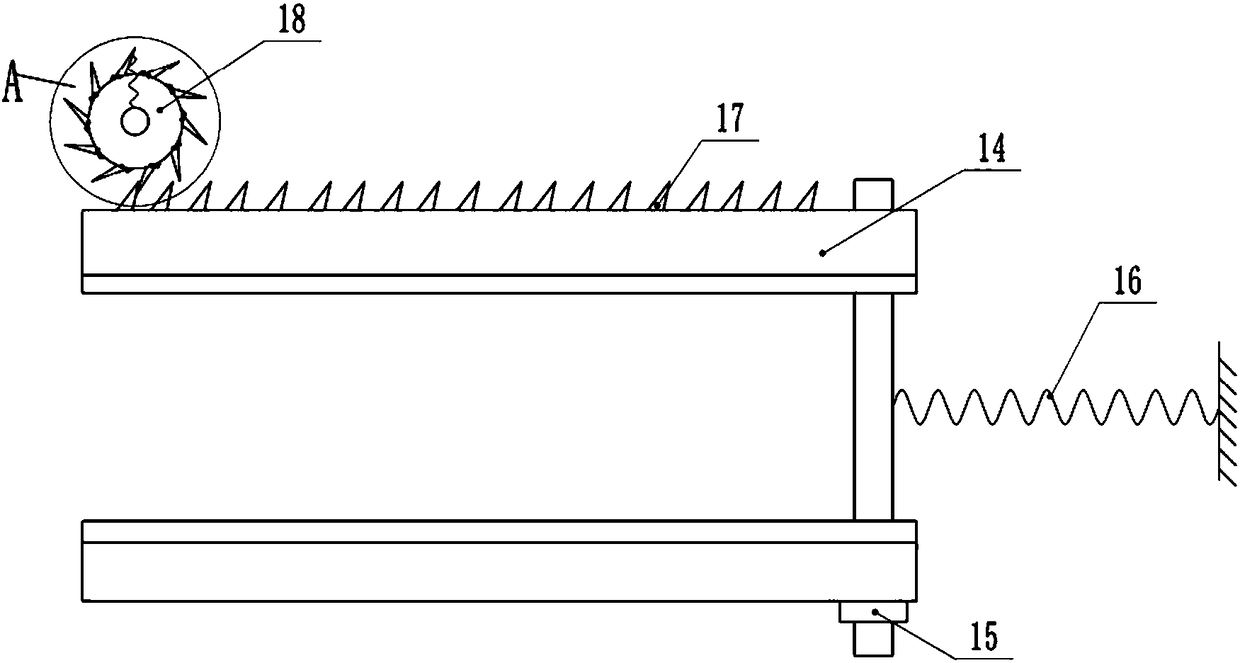

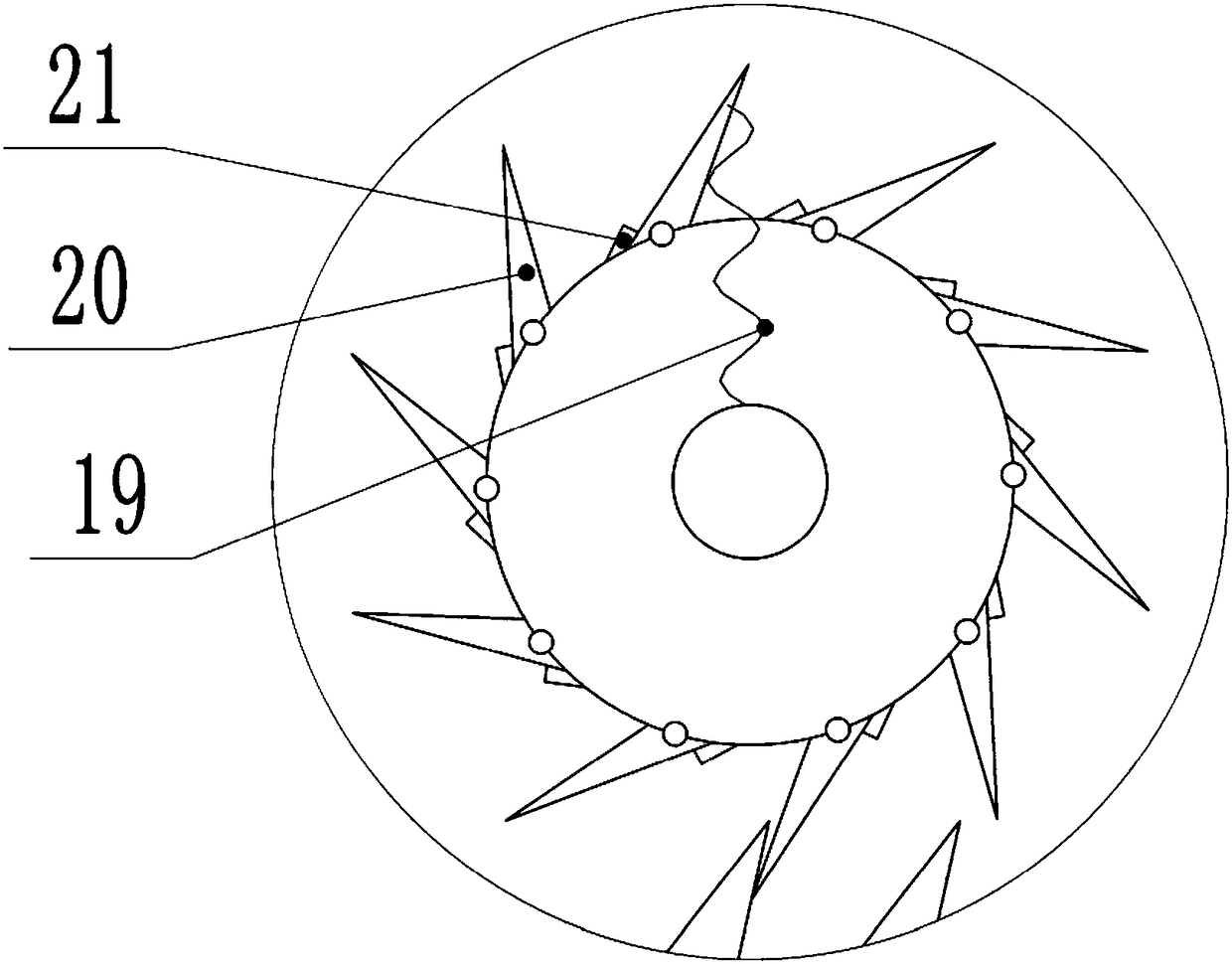

The invention belongs to the technical field of grinding equipment and particularly discloses a strip-shaped plate grinding device. The strip-shaped plate grinding device comprises a base and workingtables fixedly connected to the base. Telescopic rods are arranged on the working tables, and a fixed table is fixedly connected to the upper ends of the telescopic rods. Moving rods are arranged on the fixed table, and the lower ends of the moving rods are provided with gear teeth which are located in the base. Two gears engaged with the moving rods are arranged in the base, and a lifting table is engaged between the two gears. The lifting table and the fixed table are each provided with a grinding disc and a motor for driving the grinding disc to rotate. Material frames used for storing plates are arranged on the working tables, and through holes are formed in the middles of the working tables. First ratchets are arranged on one sides of the material frames, and rotary discs are arrangedon the working tables. Second ratchets are hinged to the rotary discs, and rotary shafts are fixedly connected to the rotary discs. Shaft sleeves are slidably connected to the rotary shafts, and springs are connected between the second ratchets and the shaft sleeves. Transmission mechanisms are arranged between the rotary shafts and output shafts of the motors, and the upper ends of the shaft sleeves are fixedly connected to the transmission mechanisms.

Description

technical field [0001] The invention belongs to the technical field of grinding equipment, and in particular relates to a strip-shaped plate grinding device. Background technique [0002] Grinding machines are widely used in finishing and surface polishing in the manufacturing industry. With the development of science and technology, product processing equipment is also developing at a high speed. The quality of finished products is closely related to the effect of processing. Grinding is required in many aspects The machine will polish the product, which can make the product more perfect, but If the effect is not good, it may greatly affect the quality of the product. The existing grinding machine can only polish the single layer of the accessories. When grinding the double layer, it needs to be repeatedly operated for grinding, which wastes a lot of time and increases manpower. The amount of labor and low work efficiency. [0003] In order to solve the problem, Chinese ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24B27/00B24B41/06B24B55/06B24B41/02B24B7/07B24B55/00

CPCB24B7/07B24B27/0076B24B41/02B24B41/06B24B55/00B24B55/06

Inventor 肖福禄

Owner CHONGQING JIANAN IND & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com