Joinery board grinding device for furniture production and processing

A woodworking board and furniture technology, which is applied in metal processing equipment, grinding machines, manufacturing tools, etc., can solve the problems of inability to grind and shape, the grinding structure is small, and the operation of adjusting the fixed structure is not convenient enough, and the effect of fixing and convenient is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

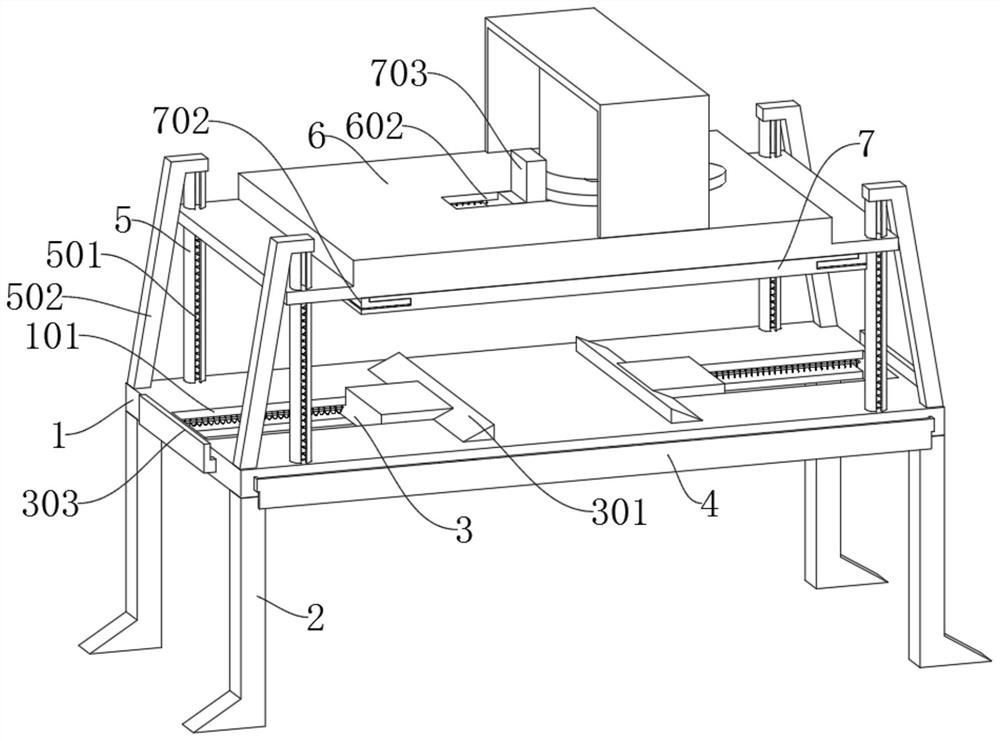

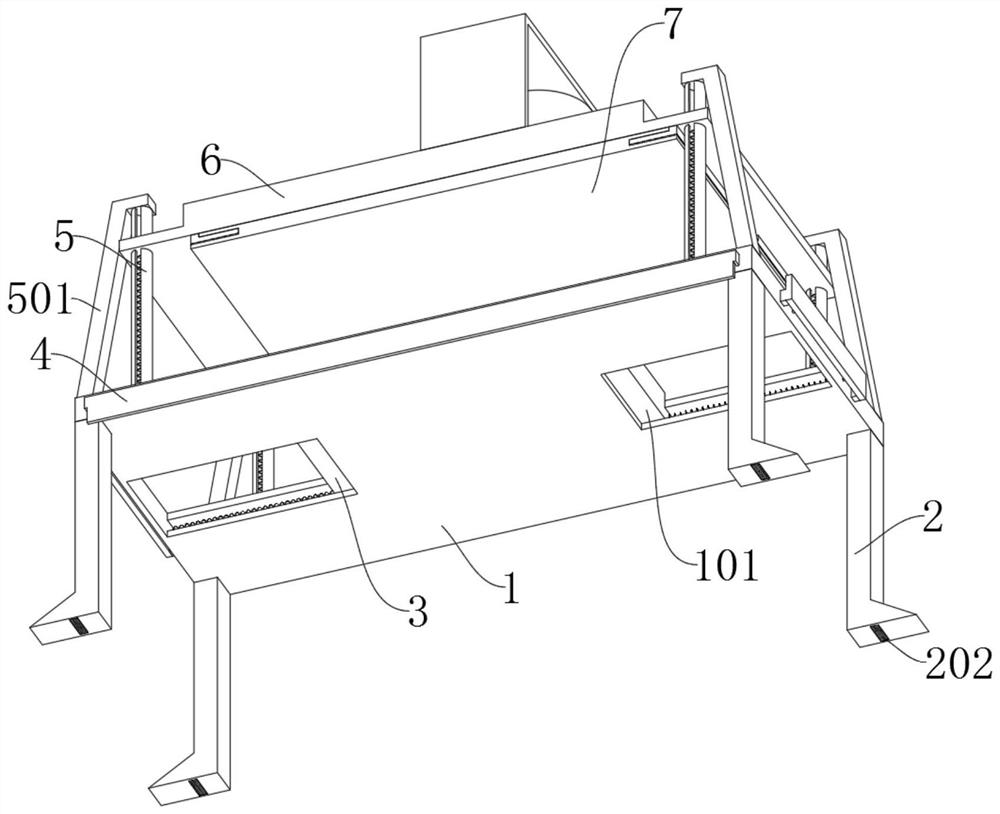

[0035] as attached figure 1 to attach Figure 9 Shown:

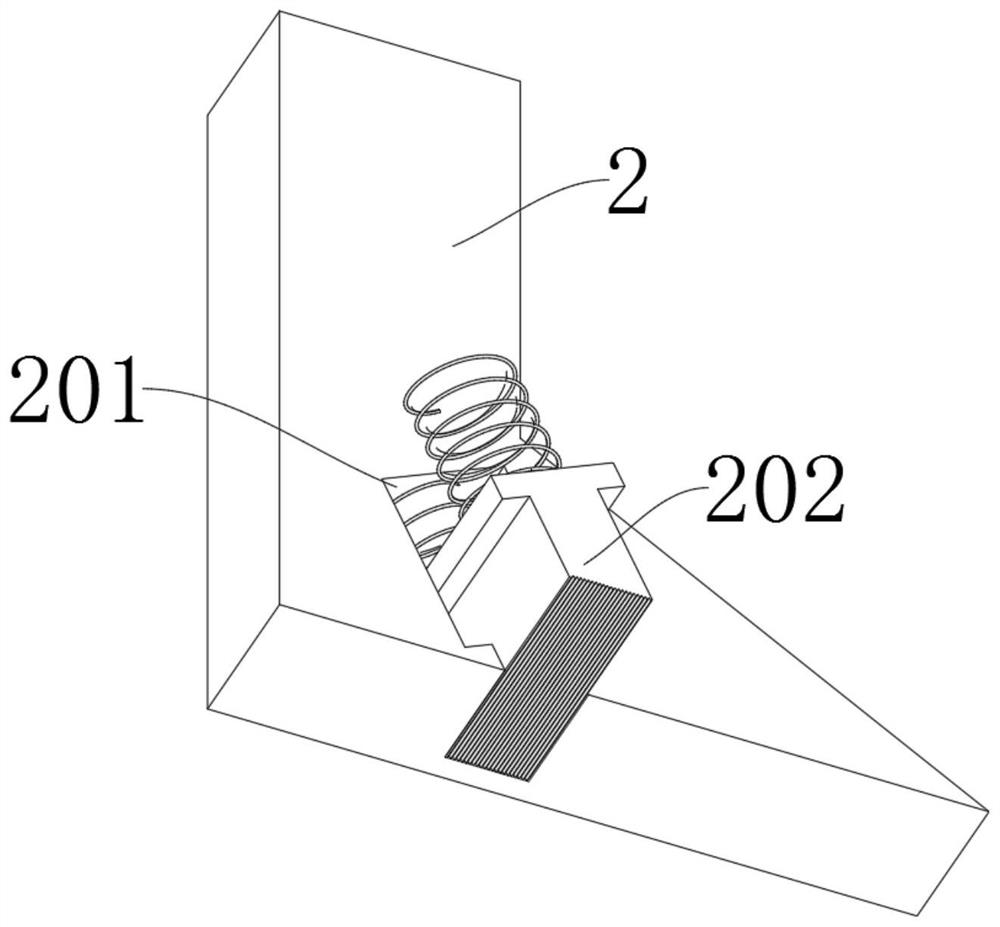

[0036] The invention provides a woodworking board grinding device for furniture production and processing, which includes a main body 1, a support member 2, a force receiving member 3, a side member 4, a guide rod 5, a moving plate 6 and a grinding member 7; the main body 1 is a rectangular plate-shaped structure , and the main body 1 has been frosted; the support member 2 is at the bottom corner of the main body 1, and the top of the support member 2 is connected to the bottom corner of the main body 1 through a fixed connection; the side member 4 is at the bottom corner of the main body 1 The front end, and the clamping plate 401 of the side piece 4 is installed in the inside of the side groove 102, and the two sides of the outer end of the clamping plate 401 are connected with the inside of the side groove 102 by springs; the bottom of the guide rod 5 and the top corner of the main body 1 The positions are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com