Grinder for part machining

A technology for parts processing and grinding machines, which is applied in the field of grinding machines for parts processing, can solve problems such as troublesome operation and low efficiency, and achieve the effects of improving processing efficiency, avoiding hardness reduction, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

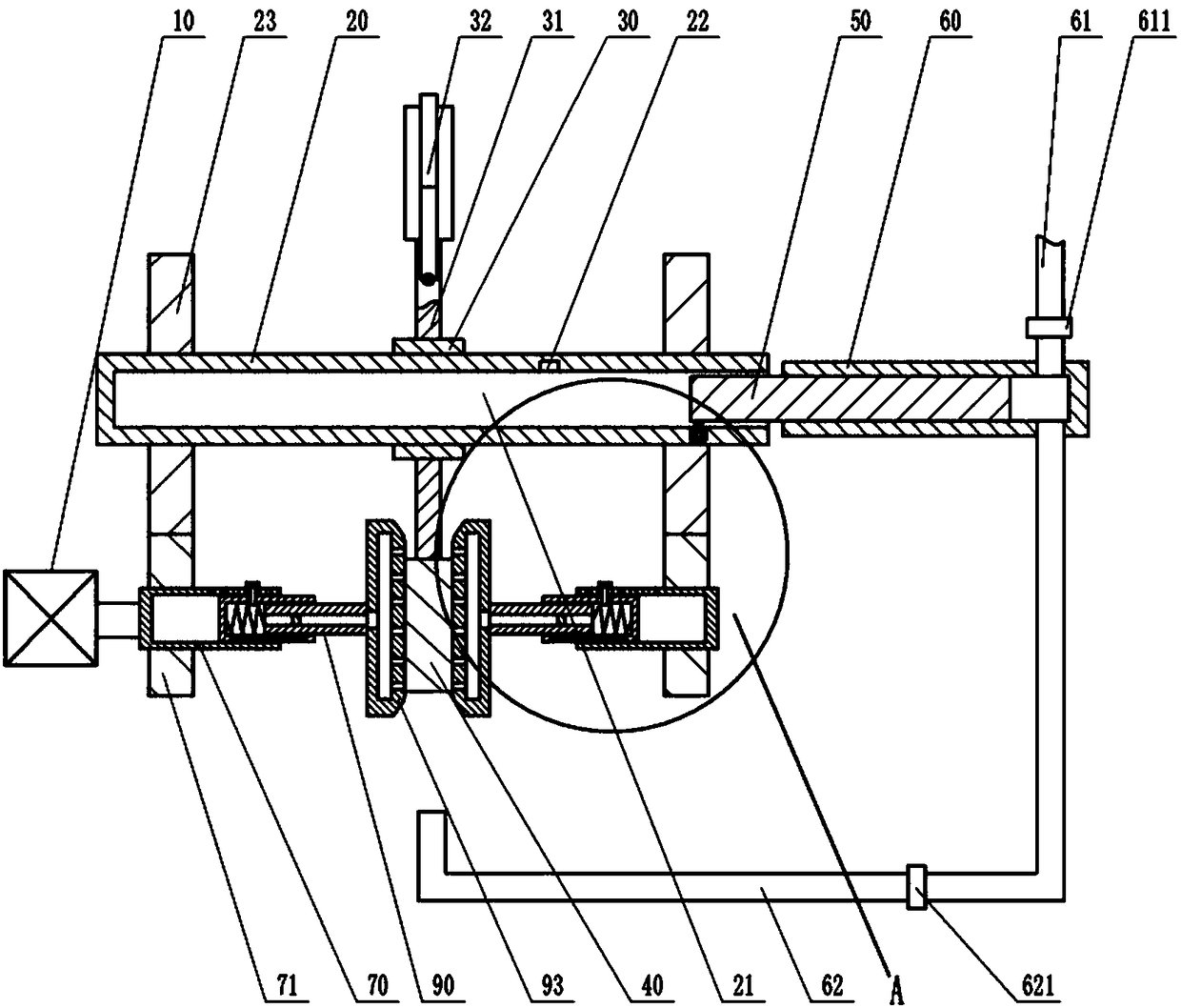

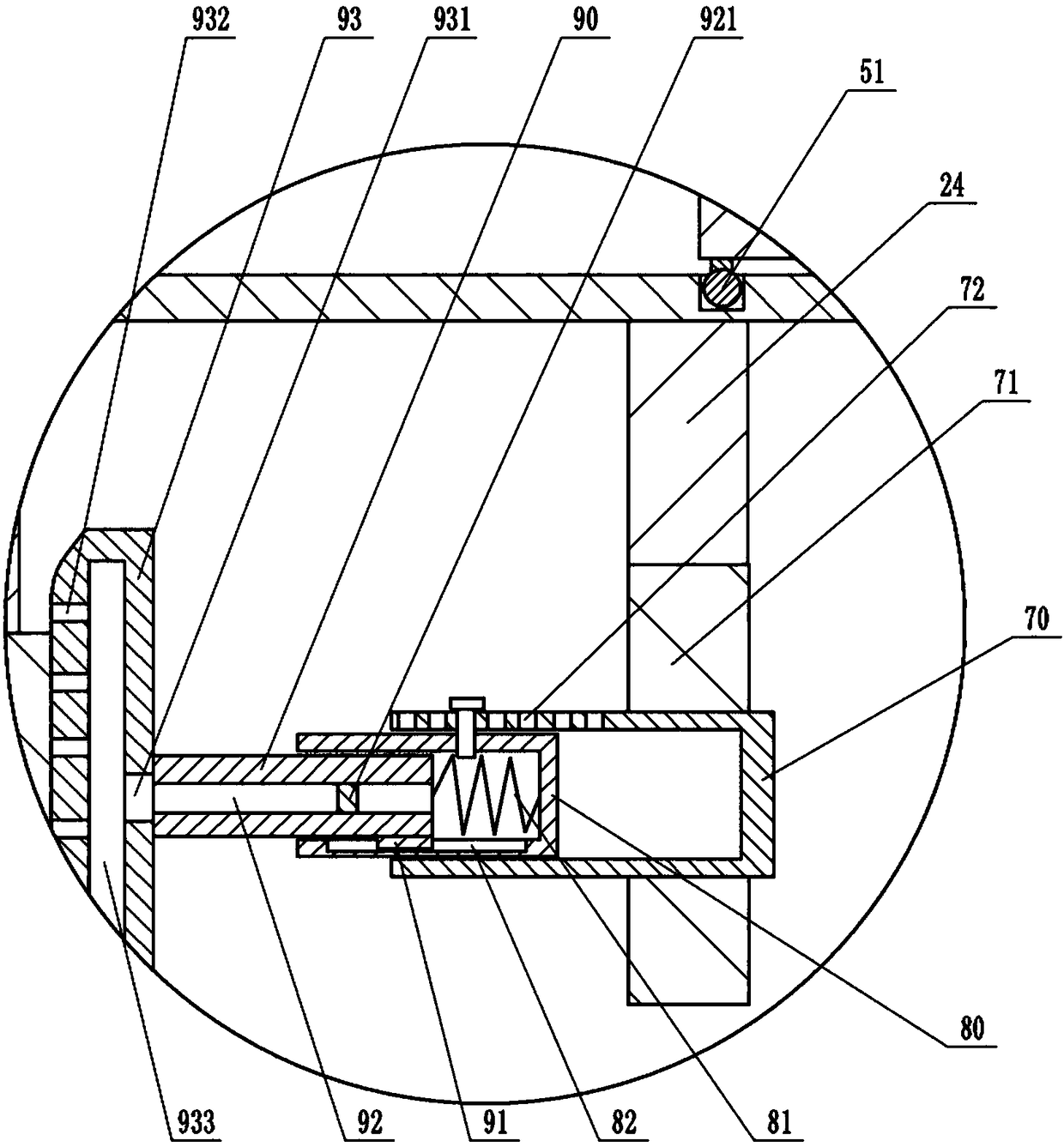

[0019] Instructions attached Figures 1 to 2 The reference signs in include: motor 10, rotating shaft 20, cavity 21, curved groove 22, second gear 23, fixed ring 30, cross bar 31, clamp 32, parts 40, plunger 50, rolling ball 51, piston Barrel 60, water inlet pipe 61, one-way water inlet valve 611, drain pipe 62, one-way drain valve 621, outer rod 70, first gear 71, second threaded hole 72, first rod 80, spring 81, chute 82 , the second rod 90, the protrusion 91, the through cavity 92, the one-way intake valve 921, the grinding disc 93, the channel 931, the through hole 932, and the air cavity 933.

[0020] Such as figure 1 , figure 2 As shown, the grinding machine for parts processing includes a frame, a transmission unit, a motor 10 fixed on the frame, and two grinding units respectively used for grinding the opposite sides of the parts 40, and the two grinding units are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com